Multifunctional hard alloy saw blade for doors and windows as well as woodworking industry

A hard alloy, multi-functional technology, used in metal sawing equipment, saw blades, circular saws, etc., can solve the problems of increased operating costs for end users, short service life of saw blades, and uneven end faces, reducing work efficiency. , Improve heat dissipation performance, eliminate uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

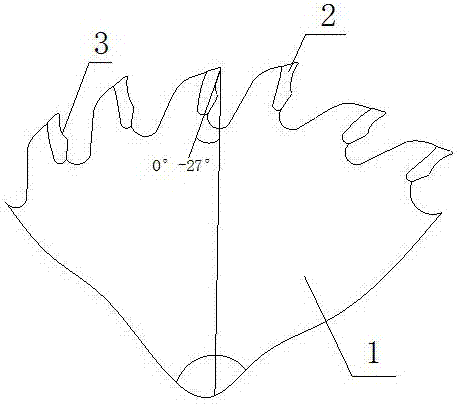

[0021] Such as figure 1 As shown, the multifunctional carbide saw blade used in the door, window and woodworking industries includes a number of arc-shaped teeth 2 arranged in a staggered front and rear on the periphery of the saw blade body 1, and all arc-shaped teeth 2 are of equal height, that is, all arc-shaped teeth 2 The distance from the central hole of the saw blade body 1 to the tip of the arc-shaped tooth is the same.

[0022] The arc-shaped tooth 2 means that all the rake angles of the teeth on the saw blade are arc-shaped. Each arc-shaped tooth 2 is composed of two small arc-shaped teeth staggered forward and backward (not shown in the figure). The included angle between the tangent to the top of the curve 3 on the curved surface of the curved tooth 2 and the line connecting the top to the center of the saw blade is 0°-27°.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com