a welding method

A welding method and welding parameter technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor arc accessibility at the root of the weld, and the welding quality cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

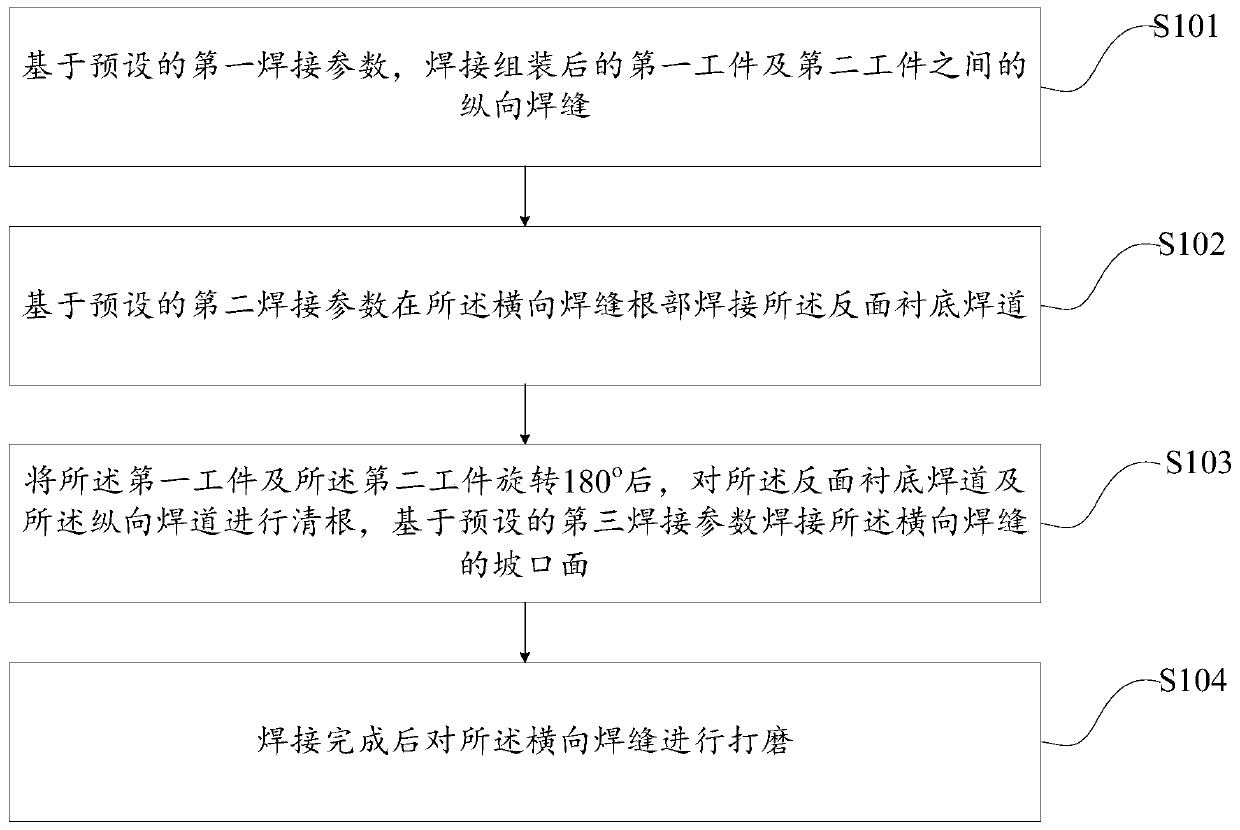

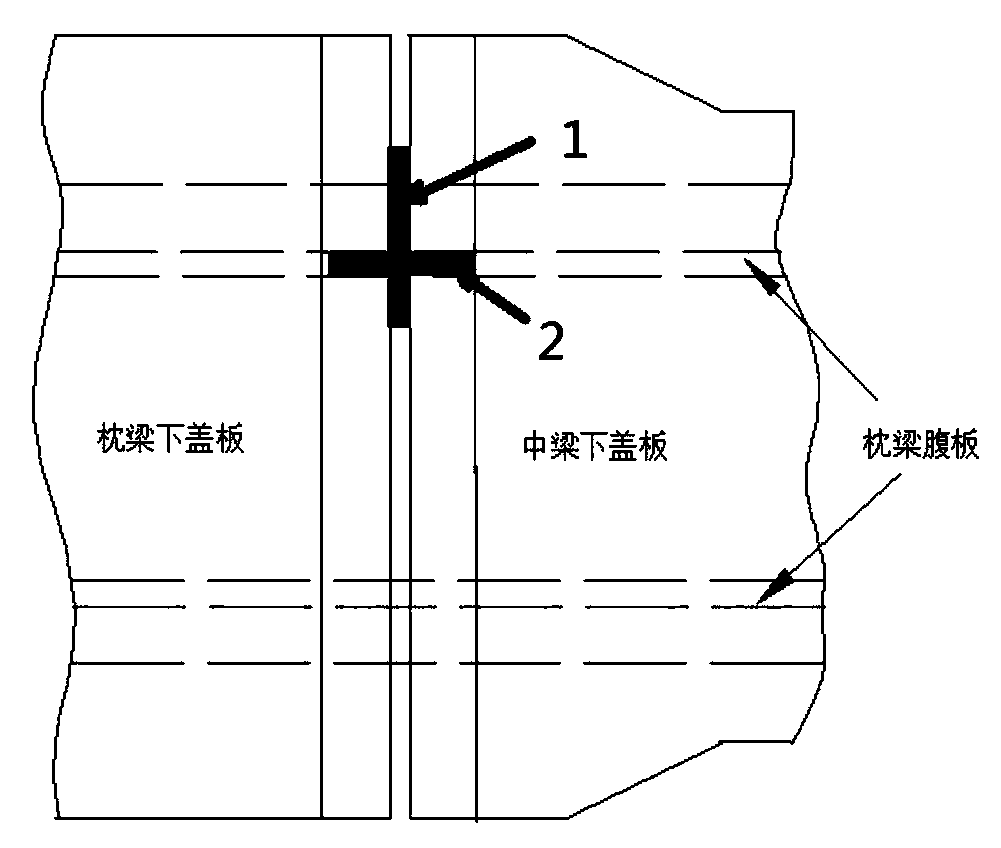

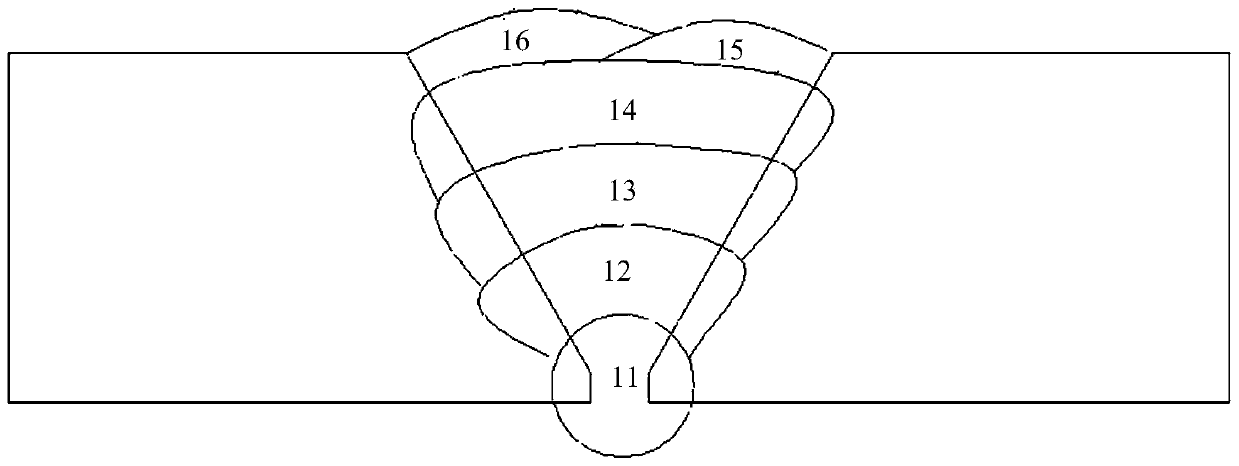

[0031] In order to solve the technical problem that the arc accessibility at the root of the weld seam is poor due to the characteristics of the weld seam distribution structure when welding the "cross" weld seam in the railway freight car in the prior art, and the welding quality cannot be guaranteed. , the present invention provides a welding method, which is applied to a "cross" weld, the method comprising: based on a preset first welding parameter, welding the assembled longitudinal weld between the first workpiece and the second workpiece ; There is also a transverse weld between the first workpiece and the second workpiece, and there is an angle between the transverse weld and the longitudinal weld; based on the preset second welding parameters in the transverse weld Welding the reverse substrate weld bead at the seam root; after rotating the first workpiece and the second workpiece by 180°, cleaning the reverse substrate weld bead and the longitudinal weld bead, based on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com