Preparation method of cold spraying coating based on heat treatment aluminum alloy powder

An aluminum alloy, cold spray technology, applied in pressure inorganic powder coating and other directions, can solve the problem of coating strength and toughness constraints, and achieve the effect of improving comprehensive mechanical properties, improving plastic deformation ability, ensuring fluidity and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

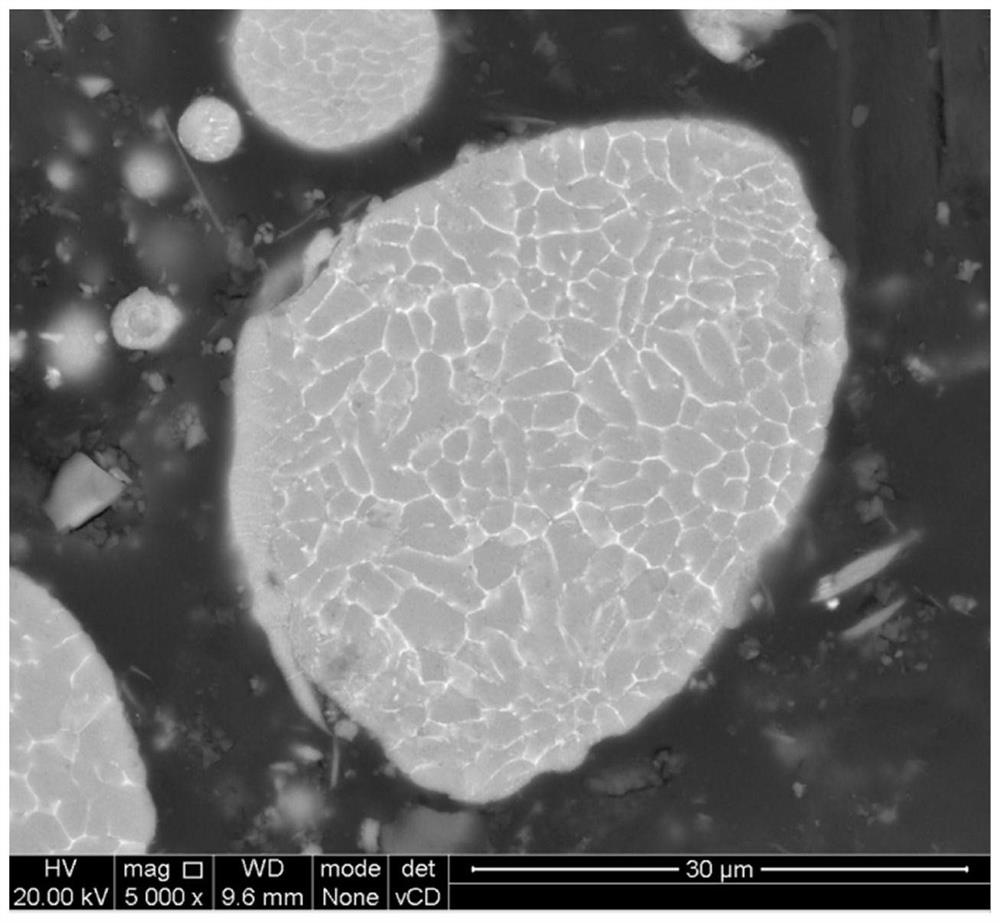

[0033] In this embodiment, the heat treatment method using 7075 aluminum alloy powder for cold spraying includes the following steps:

[0034] 1) Obtain 7075 aluminum alloy powder by gas atomization method.

[0035] Wherein, the proportion of the alloy powder with particle size less than or equal to 3 μm is less than or equal to 5%, the proportion of powder with particle size of 3 μm-60 μm is greater than or equal to 90%, and the proportion of powder with particle size of powder greater than or equal to 60 μm is less than or equal to 5%.

[0036] Powder cumulative particle size distribution D10≤6μm, D50≤23μm, D90≤50μm.

[0037] 2) Heat treatment of the powder: put the 7075 aluminum alloy powder into a tank and put it into a rotary heat treatment vacuum furnace, and vacuumize the furnace to 7×10 -3 Pa, with the furnace heating up to 120°C, the holding time is 1h, after the holding is over, high-purity argon is introduced to protect the powder, and it is air-cooled to room temp...

Embodiment 2

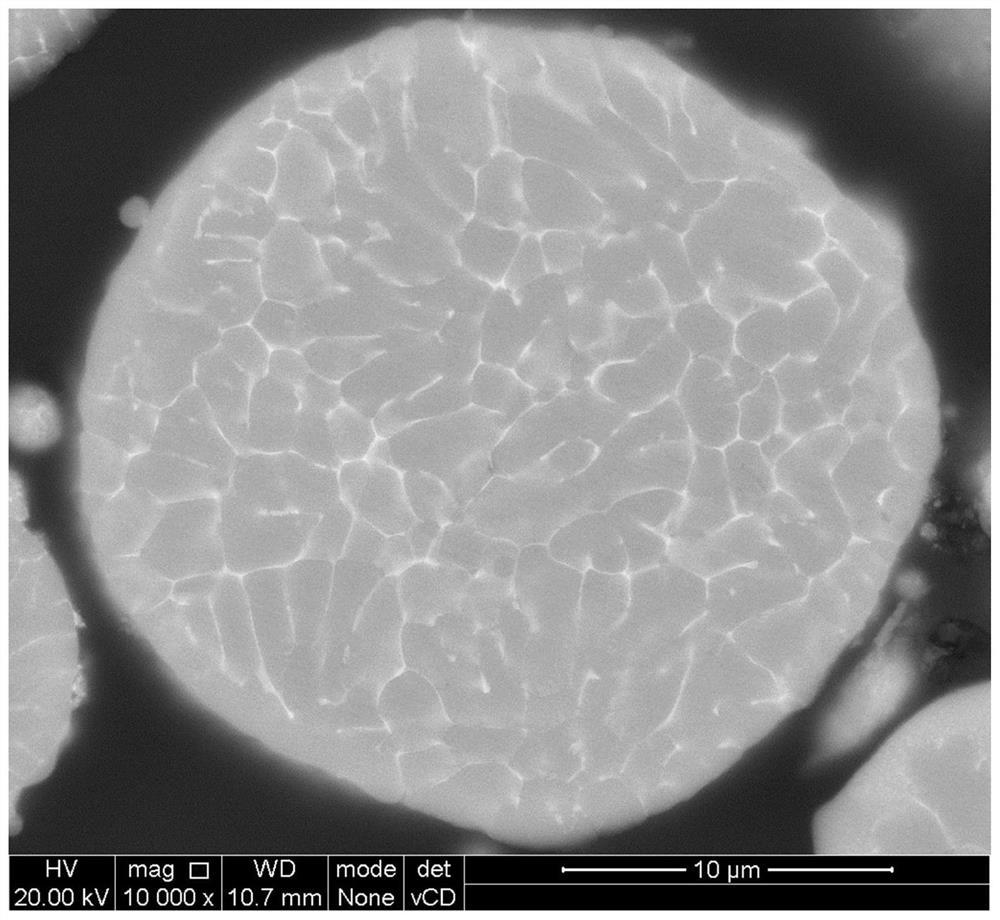

[0042] In this embodiment, the heat treatment method using 7075 aluminum alloy powder for cold spraying includes the following steps:

[0043] 1) Obtain 7075 aluminum alloy powder by gas atomization method.

[0044] Wherein, the proportion of the alloy powder with particle size less than or equal to 3 μm is less than or equal to 5%, the proportion of powder with particle size of 3 μm-60 μm is greater than or equal to 90%, and the proportion of powder with particle size of powder greater than or equal to 60 μm is less than or equal to 5%.

[0045] Powder cumulative particle size distribution D10≤6μm, D50≤23μm, D90≤50μm.

[0046] 2) Heat treatment of the powder: put the 7075 aluminum alloy powder into a tank and put it into a rotary heat treatment vacuum furnace, and vacuumize the furnace to 7×10 -3 Pa, with the furnace heating up to 140°C, the holding time is 1h, 4h, 8h, 12h, after the holding time is over, high-purity argon gas is introduced to protect the powder, and it is a...

Embodiment 3

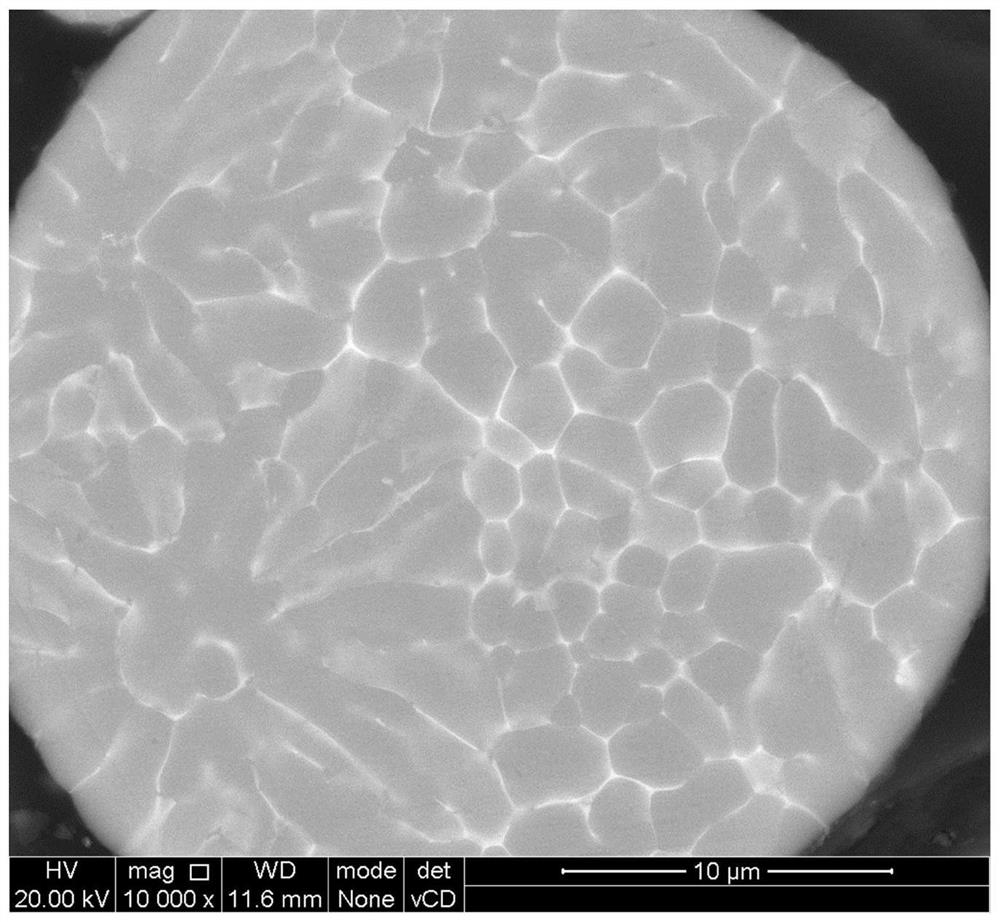

[0051] In this embodiment, the heat treatment method using 7075 aluminum alloy powder for cold spraying includes the following steps:

[0052] 1) Obtain 7075 aluminum alloy powder by gas atomization method.

[0053] Wherein, the proportion of the alloy powder with particle size less than or equal to 3 μm is less than or equal to 5%, the proportion of powder with particle size of 3 μm-60 μm is greater than or equal to 90%, and the proportion of powder with particle size of powder greater than or equal to 60 μm is less than or equal to 5%.

[0054] Powder cumulative particle size distribution D10≤6μm, D50≤23μm, D90≤50μm.

[0055] 2) Heat treatment of the powder: put the 7075 aluminum alloy powder into a tank and put it into a rotary heat treatment vacuum furnace, and vacuumize the furnace to 7×10 -3 Pa, with the furnace heating up to 160°C, the holding time is 1h. After the holding time is over, high-purity argon gas is introduced to protect the powder, and it is air-cooled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com