A kind of preparation method of high zn light weight high strength aluminum alloy

An aluminum alloy, lightweight technology, applied in the field of material processing engineering, to achieve the effects of avoiding pore defects, high energy utilization, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

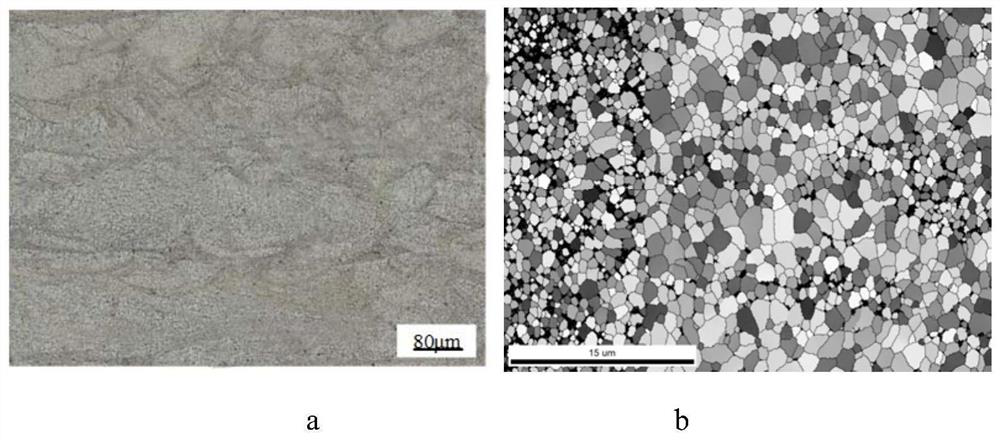

[0045] In this embodiment, Al-14Zn-2Mg-2Zr powder composition is taken as an example, and the alloy sample is tested by ball milling and selective laser melting. Adopt preparation method of the present invention as follows:

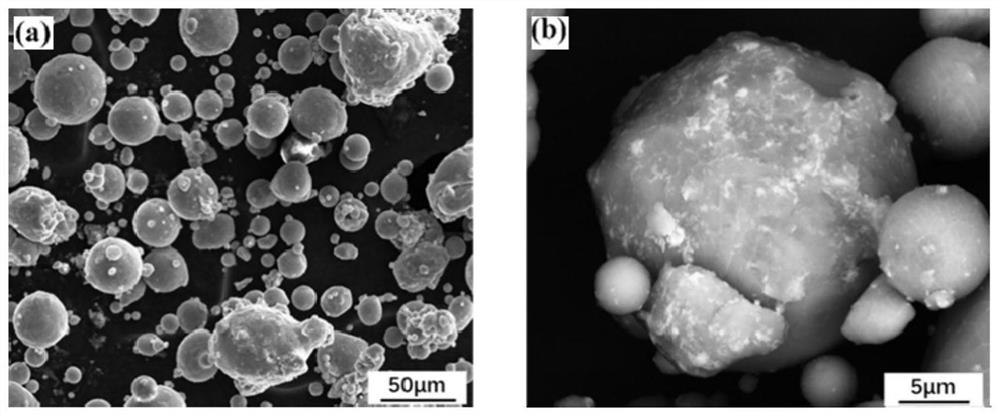

[0046] Step 1: Prepare Al powder, Zn powder, Mg powder and Zr powder respectively, the powder shapes are all spherical, the particle sizes of Al powder, Zn powder and Mg powder are all concentrated in the range of 60-80 μm, and the particle size of Zr powder is concentrated distribution In the range of 80-100μm.

[0047] Step 2: use electronic balance according to the powder ratio of above-mentioned Al-14Zn-2Mg-2Zr, the powder of different elements is weighed: promptly take by weighing 2g Zr powder, 2gMg powder and 14gZn powder and 82gAl powder, above-mentioned powder is mixed in Together.

[0048] Step 3: Use a planetary ball mill mixer to carry out mechanical mixing, feed inert gas Ar gas into the mixing tank to protect the powder from oxidation at a ...

Embodiment 7075

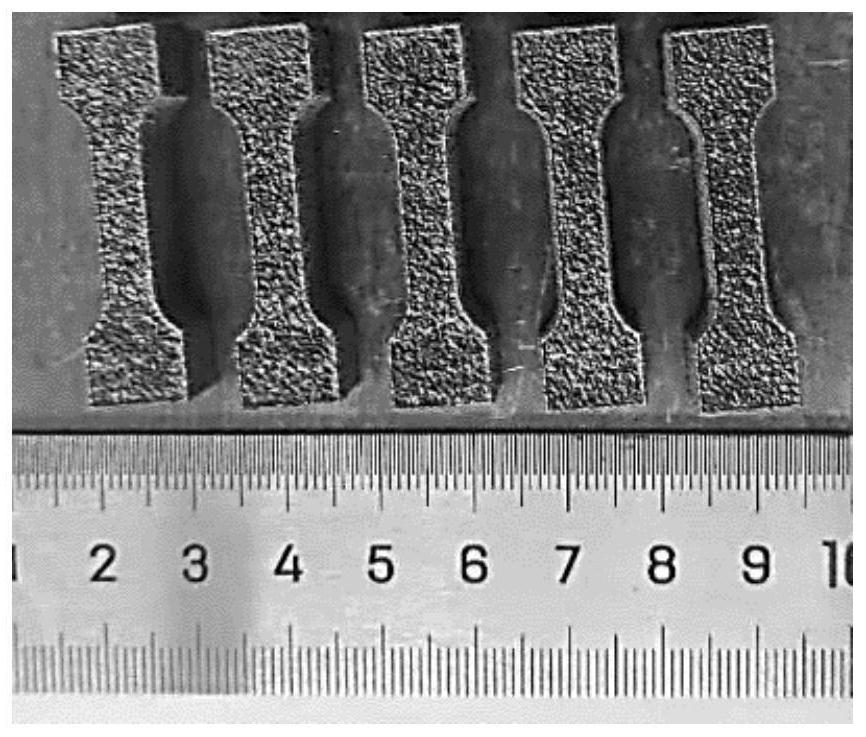

[0057] In this embodiment, 7075 aluminum alloy powder (Al-5.6Zn-2Mg) is taken as an example, and the aluminum alloy sample is formed by selective laser melting as follows:

[0058] Step 1: Draw the model through 3D drawing software, and draw the 3D model according to the pre-designed part structure and size.

[0059] Step 2: Set the thickness of powder coating in the test to 30 μm, and the software cuts the height of the planned forming component from the bottom plane into a plurality of continuous slices of equal thickness with a thickness of 30 μm.

[0060] Step 3: Pre-clamp the substrate on the forming platform, adjust the level of the substrate to ±0.025mm, fix the cooling cavity at the bottom of the substrate and near it, and inject 0°C cooling liquid with a flow rate of 5L / min.

[0061] Step 4: Set the process parameters. The laser spot diameter used in the scanning process is 0.1mm, the laser scanning distance is 0.1mm, the laser power is 360W, the laser scanning rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com