A multi-nested high-speed experimental water tunnel

A nested and experimental technology, applied in the research field of hydrodynamics experiment technology, can solve the problems of unstable flow, affecting the smooth development of physical model experiments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

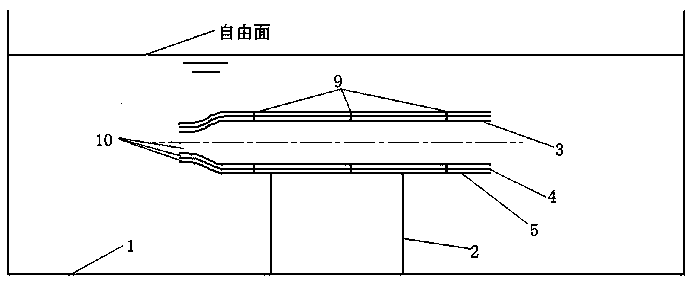

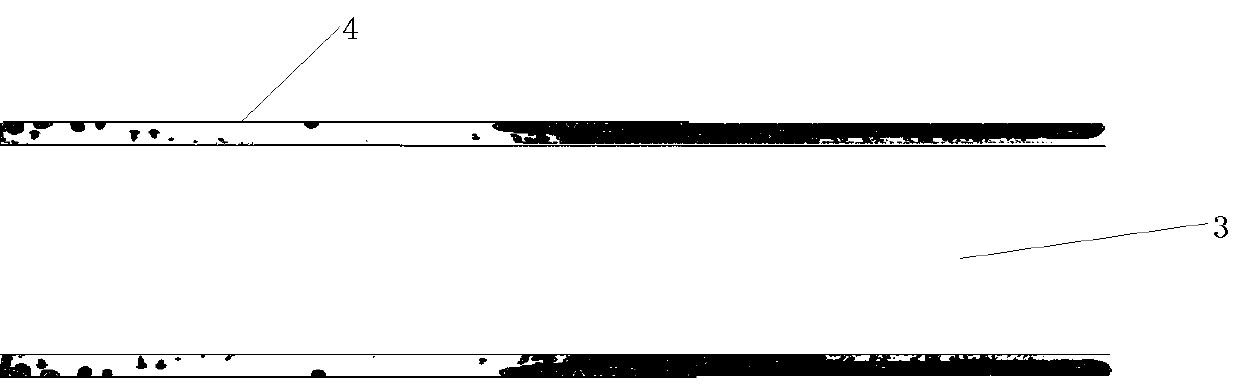

[0022] A schematic diagram of a multiple nested high-speed experimental water tunnel in this embodiment is as follows figure 1 As shown, it includes a large experimental pool 1, a main water pipe 3, a plurality of control water pipes and a plurality of water pumps; a plurality of control water pipes are sequentially nested outside the main water pipe 3, and gaps are provided between adjacent pipes; The two ends of the main water pipe 3 and each control water pipe are respectively provided with an outlet 10 and an inlet, and each outlet 10 is connected to a different water pump;

[0023] The size of the gap between adjacent tubes is related to the shape of the outlet 10, the diameter of the tube, and the length of the test section during the physical model test, and can be set according to specific experiments.

[0024] In the present invention, the main waterway pipe 3 and a plurality of control waterway pipes are nested, and the outlets 10 of the main waterway pipe 3 and each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com