Device and method for distinguishing matrix pores from microcracks of shale reservoir

A shale reservoir and micro-fracture technology, applied in the field of petrophysics, can solve the problem of accurately distinguishing matrix pores and micro-fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

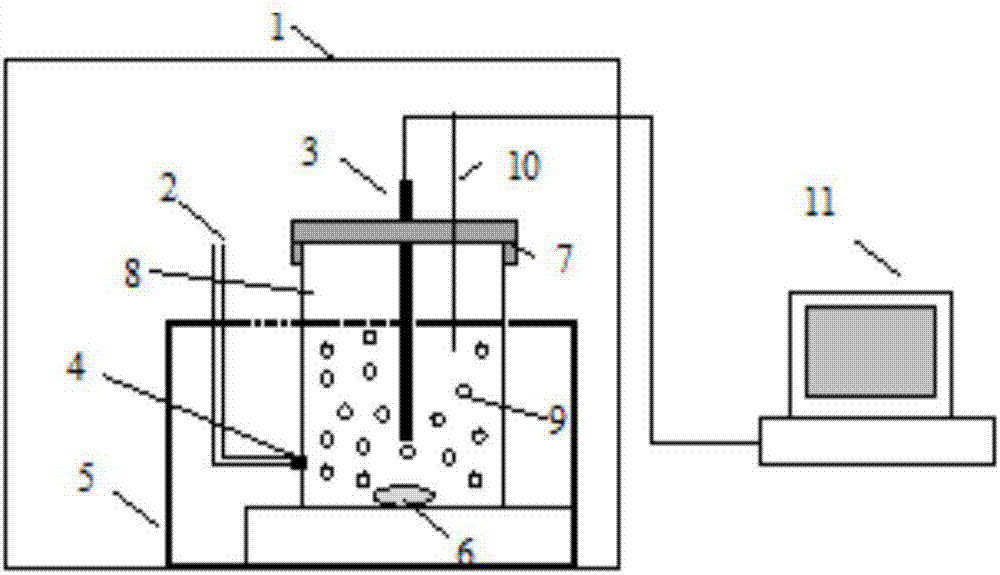

[0038] combine figure 1 As shown, in one embodiment of the present invention, a device for distinguishing shale reservoir matrix pores and micro-fractures includes an analysis control unit, a temperature control unit, an ion measurement unit and a liquid level control unit. The temperature control unit is used to control the constant temperature of the experiment process, including a thermostatic chamber 1 , a thermostatic bath 5 and a temperature sensor 10 arranged in the thermostatic chamber 1 . The ion measurement unit includes an airtight container that is located in the thermostatic tank 5 and contains the sample mixture, and a conductometer 3 that is located in the thermostatic chamber 1 and measures the conductivity of the sample mixture; the temperature sensor 10 is arranged in the airtight container. The liquid level control unit is arranged in the constant temperature tank 5, including the scale tube 2 connected to the lower end of the closed container, and the filte...

Embodiment 2

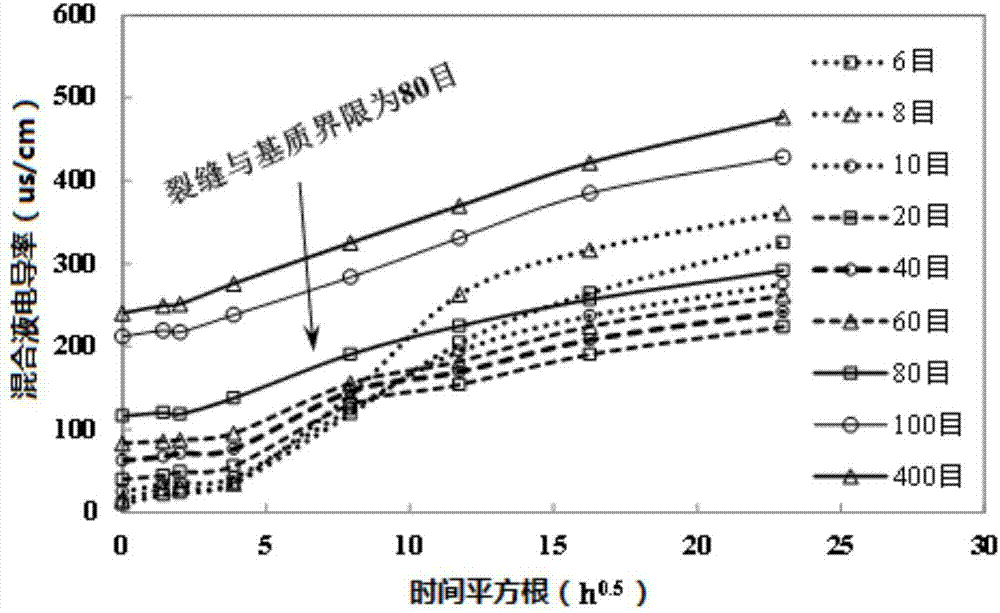

[0046] A method utilizing the device of embodiment 1 to distinguish shale reservoir matrix pores and micro-fractures, comprising the steps of:

[0047] 1) Pulverize the shale sample into particles, and then sieve the particles with a 6-mesh sieve to obtain sample particles with a particle size of 3350 μm;

[0048] 2) drying the sample particles at 105°C so that their quality does not change;

[0049] 3) Take 10g of dried sample particles and 200mL of distilled water and add them to a 250mL glass container respectively. The salt ions in the sample particles will be dispersed into the water to obtain a sample mixture; insert the lower end of the conductivity meter through the sealing cover into the sample for mixing liquid, and keep a distance of 4-6cm from the bottom of the glass container;

[0050] 4) Turn on the magnetic stirrer to stir for 2 minutes, then measure the initial conductivity of the sample mixture; after the stirring is completed, quickly measure the initial con...

Embodiment 3

[0053] The method for distinguishing matrix pores and microcracks in shale reservoirs is the same as in Example 2, and other steps remain unchanged, only step 1) is changed, such as:

[0054] 1) crush the shale sample into particles, and then sieve the particles with an 8-mesh sieve to obtain sample particles with a particle size of 2360 μm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com