Quiet gear wheel and method for producing such a gear wheel

A technology of gears and gear bodies, applied in additive manufacturing, components with teeth, belts/chains/gears, etc., can solve the problems of increased manufacturing costs, high cost of semi-finished products, etc., and achieve the effect of improving vibration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

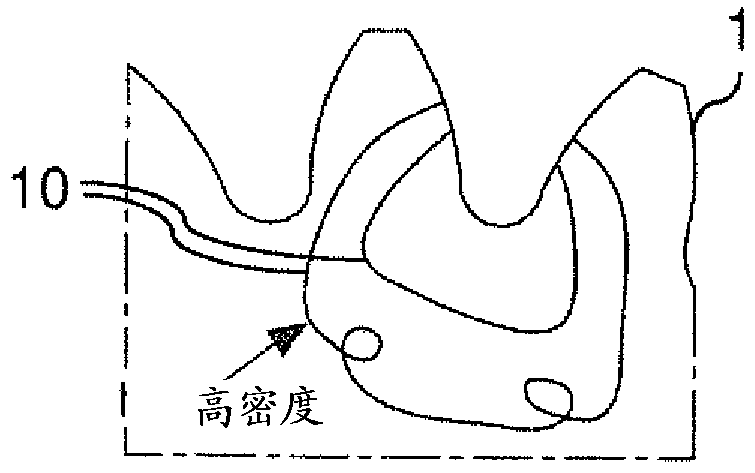

[0066] figure 1 and figure 2 Different embodiments of a closed density profile 3 arranged around an axis of rotation 2 of a gear wheel 1 are shown. The corresponding geometry of regions of different densities can have smooth transitions 4 or also jumpy density differences. They can have a transitional, wave-like or also sawtooth-like design.

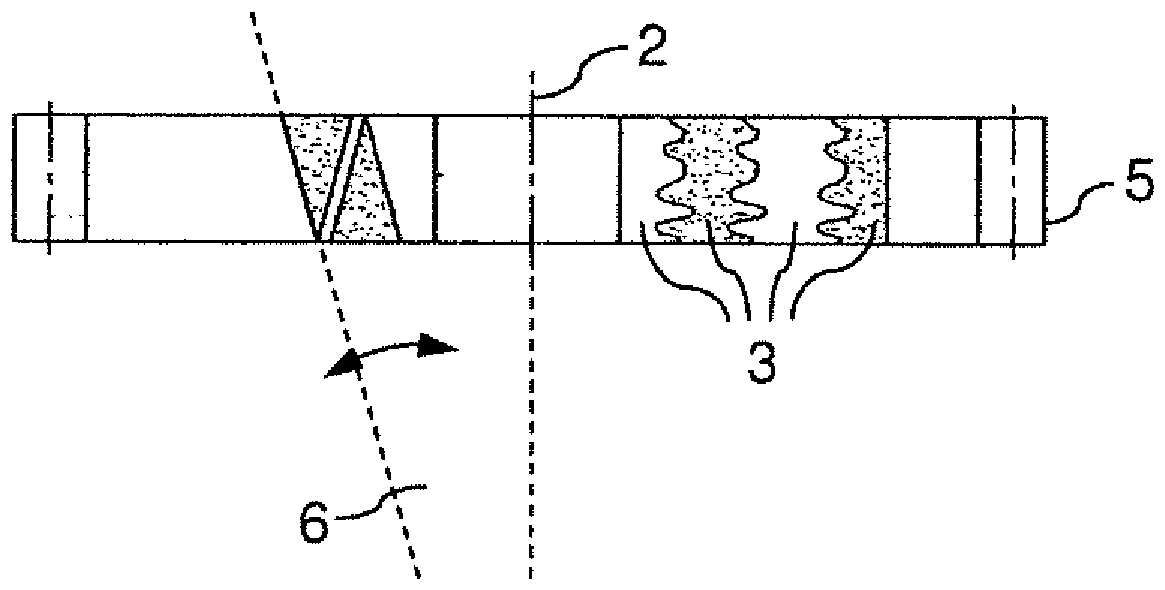

[0067] image 3 It is shown that the individual components 5 with different densities 3 can change shape in the axial direction. Along the axial extension, these density differences can run parallel to the axis of rotation 2 and at an angle 6 relative to the axis of rotation.

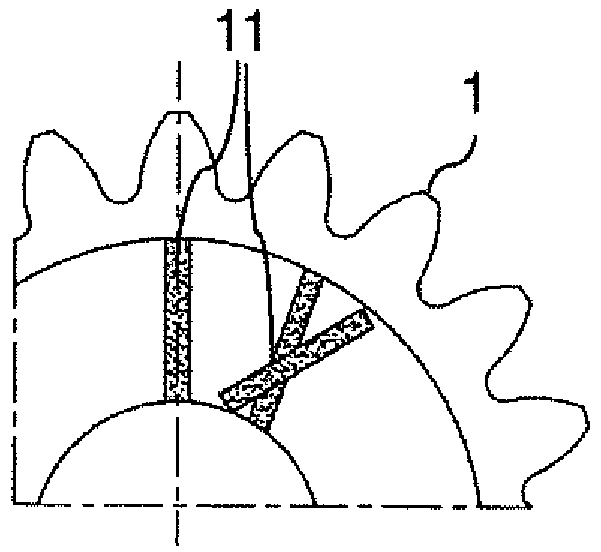

[0068] Figures 4 to 6 A local, preferably asymmetrically arranged density change 8 is shown not only in the radial direction 7 but also in the axial direction 2 . For this purpose, on the one hand the stiffness and thus the natural frequency of the gear wheel 1 can be influenced. On the other hand, bulk sound can be absorbed, deflected or also redirected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com