Small load-following nuclear power generation system using heat deformation of reflector caused by thermal expansion phenomenon

A technology of nuclear power generation and reflector, which can be used in nuclear power generation, nuclear power plants, and the conversion of reactor thermal energy into mechanical energy, etc., and can solve problems such as runaway nuclear reactions in the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

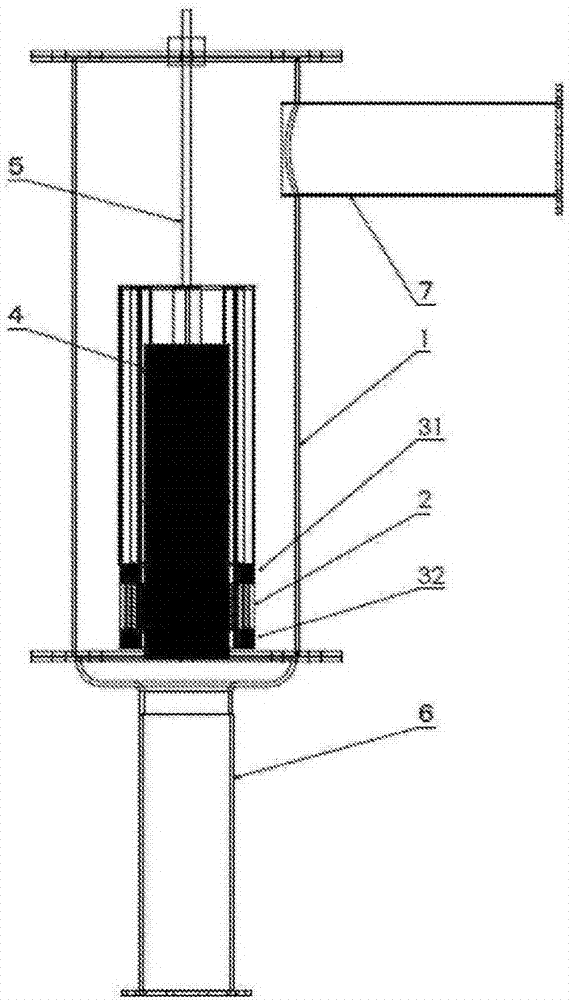

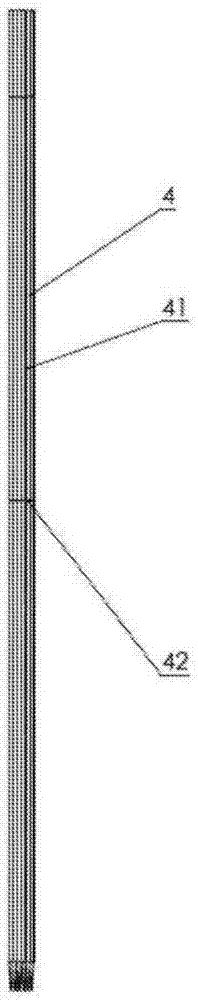

Embodiment 1

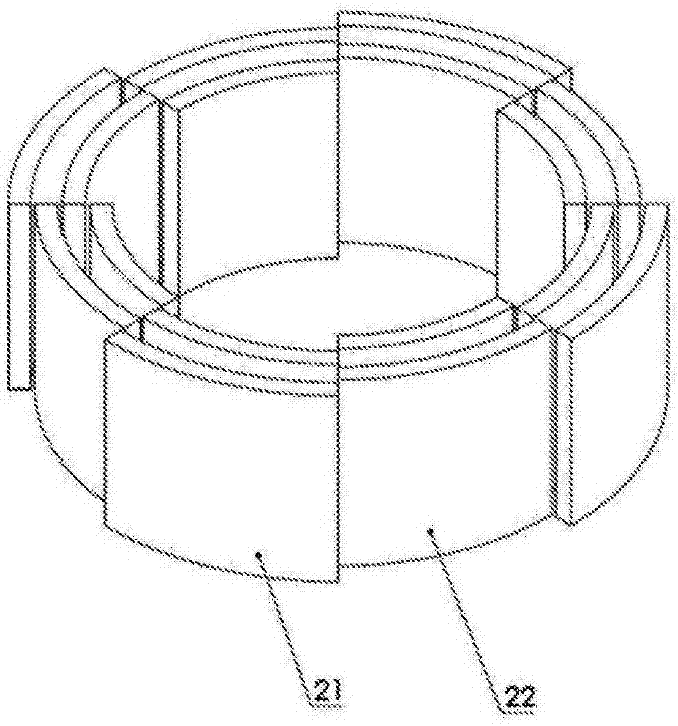

[0114] Next, refer to Figure 3A , 3B and Figure 4 , to illustrate the most important reflector in the load-following control of the present invention. Such as Figure 3A As shown, the reflector is formed of graphite and has a double structure with a thickness of 10 cm. This double structure is divided into eight parts in the circumferential direction, and each part is equipped with two kinds of reflectors A21 and B22 with different radii. When the circumferential direction is staggered, each other can be accommodated inside. Such as Figure 3B As shown, the dual structure of the reflector A21 and the reflector B22 is fixed by the reflector support plate 20 . The reflector B22 had an inner diameter of 52 cm and a height of 50 cm. By shifting such two types of reflectors with a double structure from each other, a gap (slit) can be formed between the reflector A21 and the reflector B22, thereby reducing the reflection efficiency. Carbon (for example, graphite carbon fine...

Embodiment 2

[0119] Next, it is explained that raising K eff Method for the temperature of the critical point of "1". Such as Figure 7 As shown, in addition to the reflector A21 and the reflector B22 divided into four parts, an overlapping part 23 is provided. This adjusts the width of the slit that occurs due to thermal expansion of the reflector. Figure 8 Indicates that the overlapping part of the reflector is set due to K eff Calculated results related to the width of the slit that occurs due to thermal expansion. according to Figure 8 It can be seen that K eff The temperature rise for =1 is about 500°C. In this way, in the split reflector, the K can be adjusted by adjusting the length of the overlapping portion eff =1 temperature.

Embodiment 3

[0121] Figure 9 Other examples of reflector structures of the present invention are shown. In Examples 1 and 2, split reflectors are arranged by providing slits between reflectors in the circumferential direction, thereby controlling K eff of. But in this embodiment, K is controlled by moving the reflector in the radial direction eff . Figure 9 describe its organization. In order to allow the double reflectors 21 and 22 divided into eight parts to separate from the fuel assembly as the temperature rises, the thermal expansion of the adjustment spring 26 is used. First, on the outer side of the double reflectors 21 and 22 divided into eight parts, a fixing cylinder 24 for fixing the adjustment spring 26 is arranged, and on the outer side, eight spring-driven jigs for moving the reflector are arranged corresponding to the divided reflectors. , the spring-driven jig for moving the reflector is formed by combining the adjustment spring support plate 27 , the reflector adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com