Elastic sweeping mechanism of insulator sweeping and scrubbing robot

A cleaning mechanism and cleaning removal technology, which is applied in the direction of instruments, building structures, time registers, etc., can solve the problems of high maintenance costs, ineffective cleaning, and theft of cleaning robots, so as to prevent criminals from stealing, low maintenance costs, Good cleaning and decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

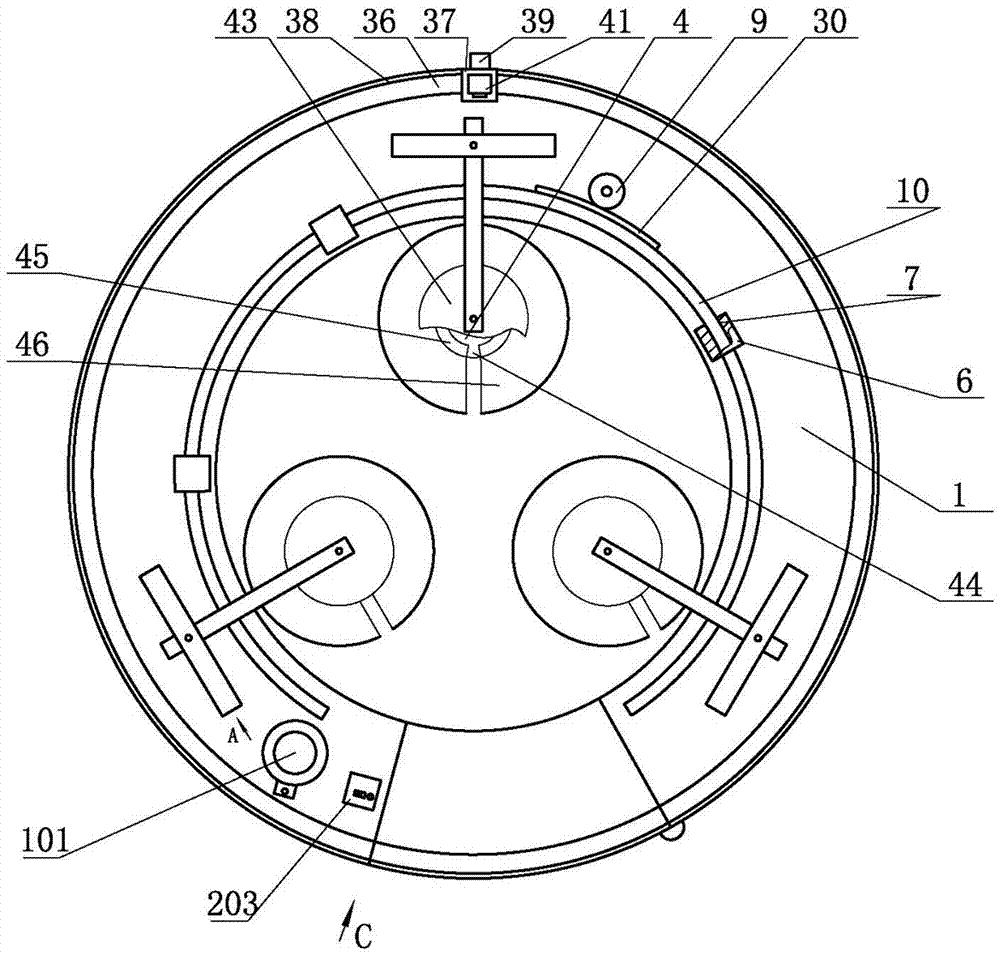

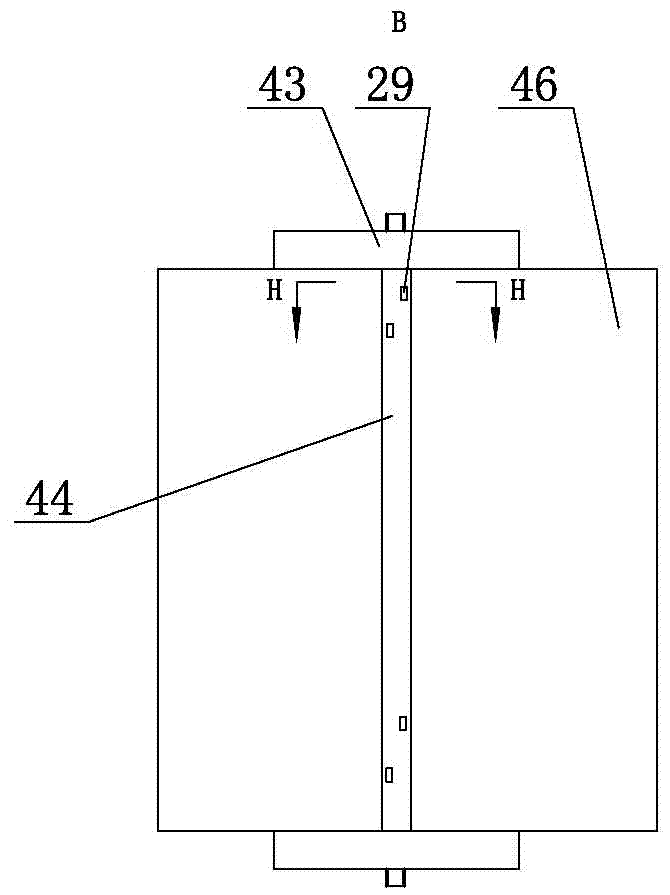

[0019]The elastic cleaning mechanism of the insulator cleaning and decontamination robot includes a circular shell 1 on which several inverted U-shaped fixing frames 2 are evenly arranged around the center of the circle, and several U-shaped cleaning mechanism brackets 3 are hinged on the shell 1 The lower end of the lower end of the cleaning mechanism support 3 is hinged with the corresponding fixed frame 2 tops, the side of the cleaning mechanism support 3 is equipped with a drive roller 4, and the bottom of the cleaning mechanism support 3 is equipped with a power motor 5, and the power motor 5 is connected with the drive roller 4 and can The driving roller 4 is driven to rotate, the upper and lower ends of the driving roller 4 are respectively equipped with limit rings 43, and a cleaning brush is installed between the two limit rings 43, and several guide blocks 6 are fixedly installed on the housing 1 along the circumferential direction, and the guide blocks 6 A guide hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com