Tubular product structure with opening groove and machining equipment and machining method of tubular product structure

A technology of opening grooves and pipes, which is applied to clothing, watch chains, decorative chains, etc., and can solve problems such as hollow wires sinking, high consumables, and affecting sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

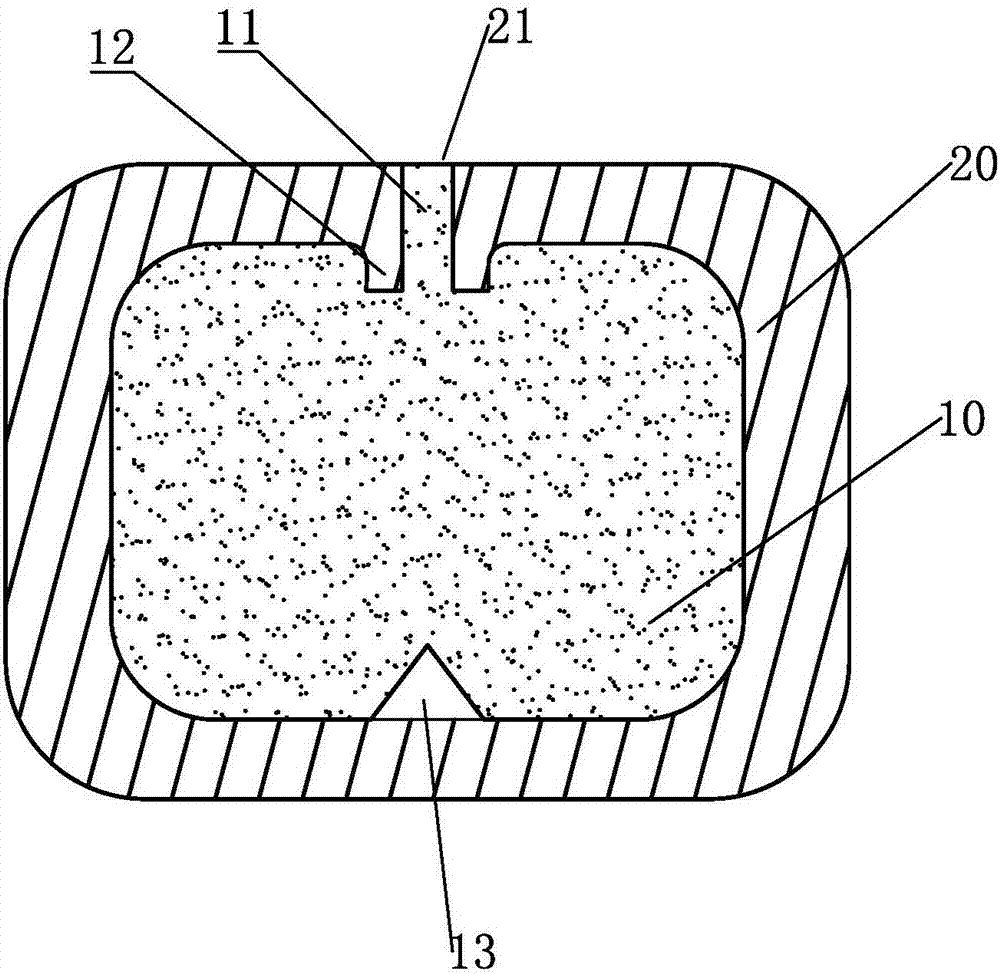

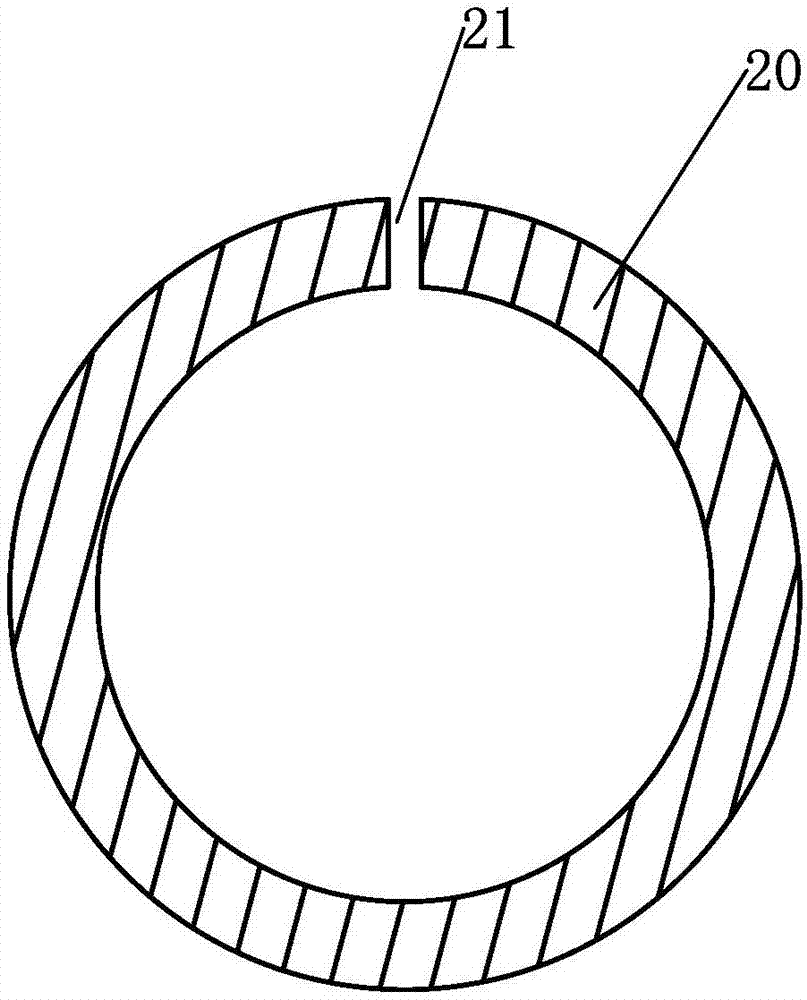

[0068] like figure 1 and figure 2 As shown, the pipe structure with an open slot includes a mandrel 10 made of iron, and a tubular body 20 wrapped around the mandrel 10 and made of gold; the tubular body 20 is provided with an open slot 21; the gap between the open slot 21 The width is 0.01-0.1 mm; the outer diameter of the tubular body 20 is 0.3-1 mm.

[0069] Further, in other embodiments, one side of the mandrel 10 is provided with a raised portion 11; the raised portion 11 is located at the opening groove 21, and a sunken portion 12 is respectively provided on both sides; the two sides of the opening groove 21 are embedded In the sag 12; the cross section of the mandrel 10 is a circular arc chamfering rectangle, the ratio of the chamfering radius to the width of the rectangle is 1: (3-5); The ratio is 1:(4-8), and the height is the same as the thickness of the tubular body 20 .

[0070] Further, in other embodiments, the other side of the mandrel 10 is provided with an...

Embodiment 2

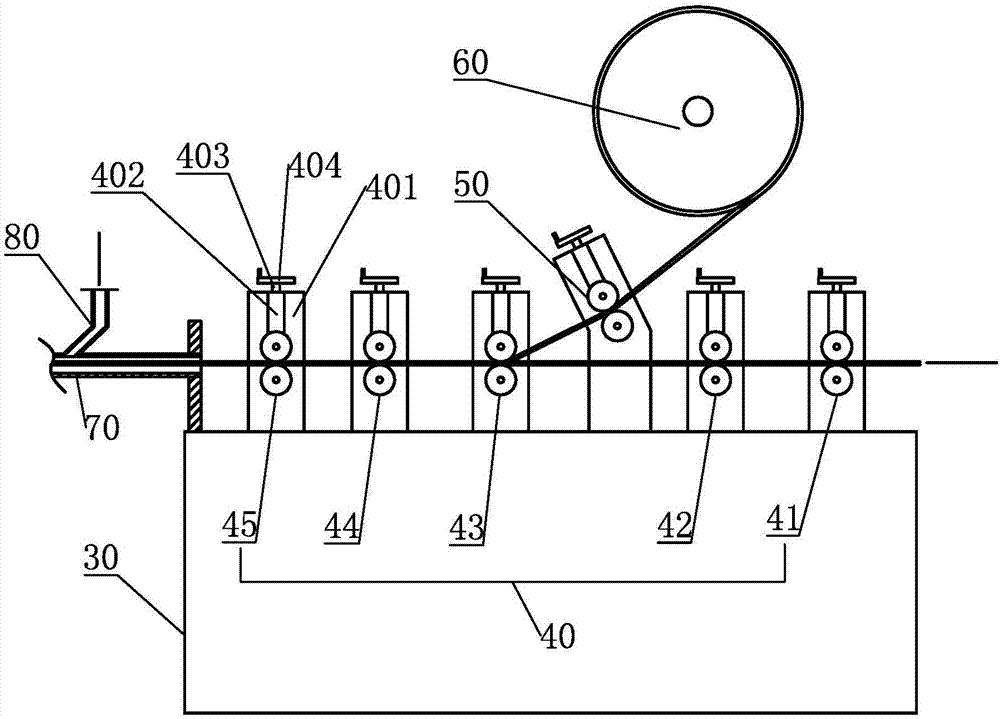

[0073] like image 3 Shown, a kind of processing equipment that is used to process the pipe structure with open slot in embodiment 1, comprises machine base 30, is located at the extrusion forming wheel set 40 (also can be called rolling forming) on machine base 30 , and a set of guide wheels 50 provided on the base 30 and used to guide the mandrel 10;

[0074] The extrusion forming wheel set 40 comprises a primary concave forming wheel set 41, a secondary concave forming wheel set 42, a primary outer wrapping wheel set 43, a secondary outer wrapping wheel set 44 and Shaping wheel set 45;

[0075] like Figure 4 As shown, the primary concave forming wheel set 41, the secondary concave forming wheel set 42, the primary outer wrapping wheel set 43, the secondary outer wrapping wheel set 44, the shaping wheel set 45 and the guide wheel set 50 each include a fixed wheel (refers to the roller located below) and movable wheel (refers to the roller located above), the wheel base...

Embodiment 3

[0089] As the processing method of the pipe structure with open groove in embodiment 1, comprises the steps:

[0090] a. The sheet-shaped acid-insoluble metal material is rolled into a semi-finished tubular body in an indented shape;

[0091] b. Embedding a mandrel with a raised portion made of an acid-soluble metal material into the recessed position of the semi-finished tubular body;

[0092] c. Continue the rolling process so that the semi-finished tubular body wraps the mandrel, leaving only one open slot, and making the protrusion of the mandrel located at the open slot;

[0093] d, further rolling processing, so that the outer diameter of the semi-finished product of the tubular body becomes smaller;

[0094] e. Process the semi-finished tubular body into jewelry products;

[0095] f. Put jewelry products into acidic solution to corrode the mandrel;

[0096] g. After the mandrel is completely corroded, remove the jewelry product from the acidic solution and clean it. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap