Automatic feeding device for long pole workpieces

An automatic loading and workpiece technology, which is applied to assembly machines, metal processing, manufacturing tools, etc., can solve problems such as the inability to complete the installation by a single person, the consumption of physical strength, and the shortage of personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The automatic feeding device for long rod workpieces of the present invention will be described in detail below in conjunction with several embodiments of the accompanying drawings:

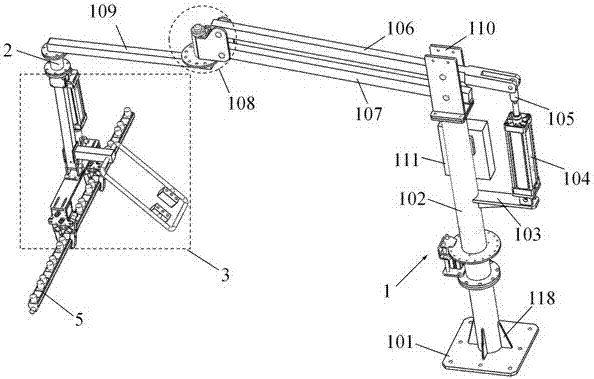

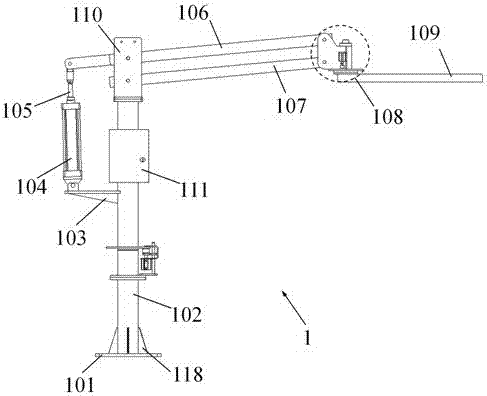

[0067] Such as figure 1 As shown, an automatic loading device for long rod workpieces includes a cantilever crane 1 and a clamp assembly connected to the cantilever crane 1 through an adapter flange 2 , and the clamp assembly includes a single clamp 3 and three clamps 4 .

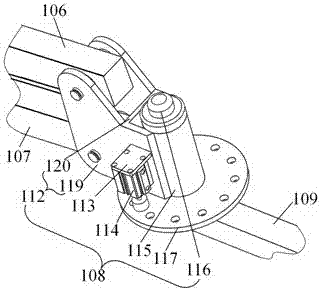

[0068] Such as figure 1 , 2 As shown, the cantilever crane 1 includes a base 101; a column 102 is vertically arranged on the base 101; two rod fixing plates 110 are vertically arranged on the top of the column 102, and a mobile cylinder mounting frame 103 is provided on the outer peripheral wall of the middle part; Cylinder 104 is installed on the mobile cylinder mount frame 103; The cylinder rod 105 of mobile cylinder 104 is connected with active rod 106; The gap between them is connected to the two rod fixing plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com