Positioning system for layered storage rack for automobile punching parts

A technology of automobile stamping parts and positioning system, which is applied in tool storage devices, manufacturing tools, etc., can solve the problems of large area, small thickness of large stamping parts, and difficult positioning, and achieve the effect of accurate positioning and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, with reference to the drawings, through the description of the embodiments, the shape, structure, connection relationship and working principle of each part involved in the specific implementation of the present invention will be further described in detail.

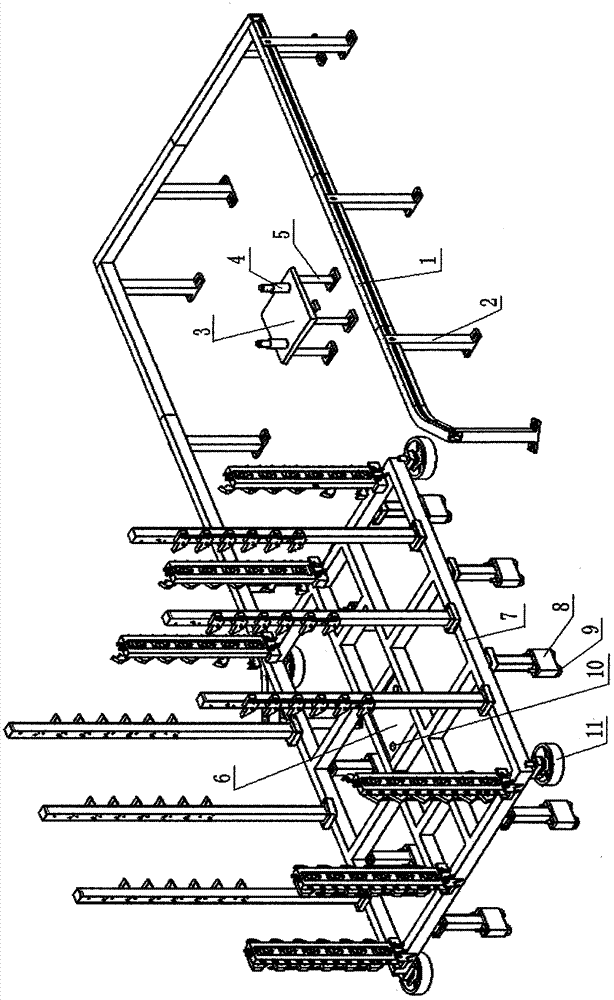

[0019] figure 1 It is a structural schematic diagram of a layered shelf positioning system for automobile stamping parts of the present invention; figure 1 A layered shelf positioning system for automotive stamping parts of the present invention is shown, including a layered shelf positioning assembly for automotive stamping parts and a flexible positioning part; the layered shelf positioning assembly for automotive stamping parts includes a positioning support and a guide rail surrounding three sides , The positioning support includes a positioning support body 3 and a support fixing rod 5. The positioning support body 3 is a horizontally placed rectangular plate that fits the positioning plate 6 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com