Compression device for soot filter carrier

A filter and carrier technology, which is applied in the field of soot filter carrier pressing devices, can solve the problems of relatively high pressing efficiency and stability, poor stability, and low scrap rate, and achieve carrier fragmentation avoidance, strong stability, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

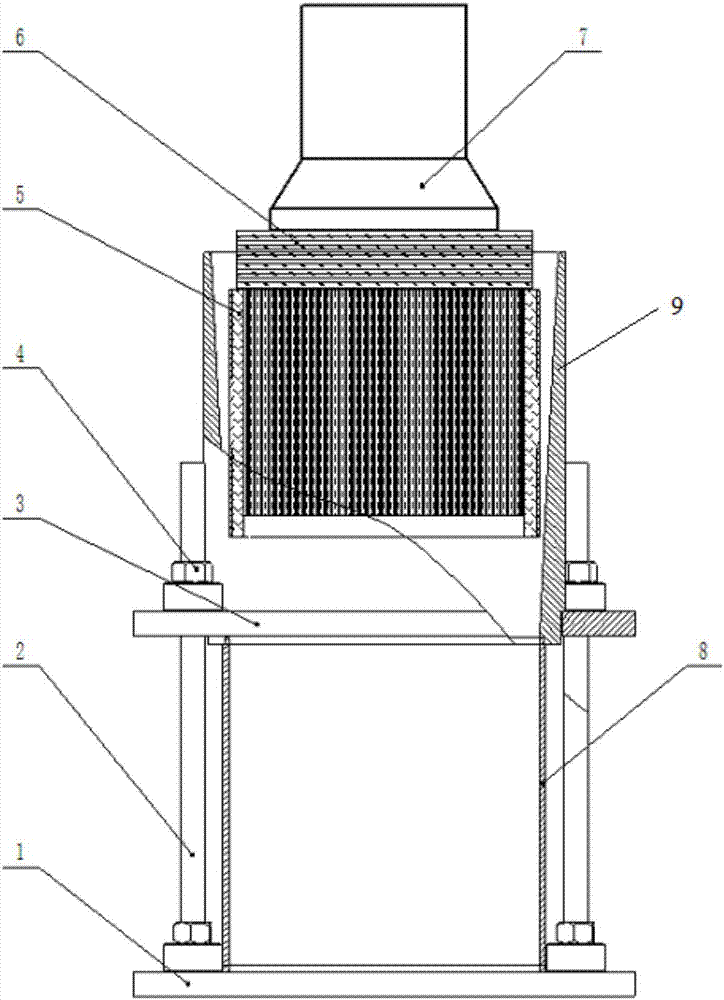

[0016] The present invention will be further described below in conjunction with specific drawings.

[0017] like figure 1 As shown, the soot filter carrier pressing device of the present invention includes a lower tray 1, and a guide upper cover 3 is arranged above the lower tray 1, and the lower tray 1 and the guide upper cover 3 are connected by a threaded guide post 2, and the upper guide The cover 3 can move up and down along the threaded guide column 2 and is positioned by the fastening bolt 4, which is used for pressing the carrier 5 at different heights; a shell 8 is arranged between the lower tray 1 and the guide upper cover 3, and the lower tray 1 and the guide upper cover 3 Both are provided with positioning notches, and the housing 8 is fixed by the positioning notches; the guide upper cover 3 is provided with a guide tube 9, the inner cavity of the guide tube 9 is inverted tapered, and the inlet diameter of the guide tube 9 is larger than that of the carrier 5 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com