Food packaging machine vacuum chamber installing component air distribution plate structure

A technology for installing components and food packaging, which is applied in the field of the air distribution tray structure of a vacuum chamber installation component of a food packaging machine, can solve the problems of easy winding of air pipes and difficult arrangement of air pipes, and achieves the effect of simple arrangement of air pipes and realization of vacuuming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

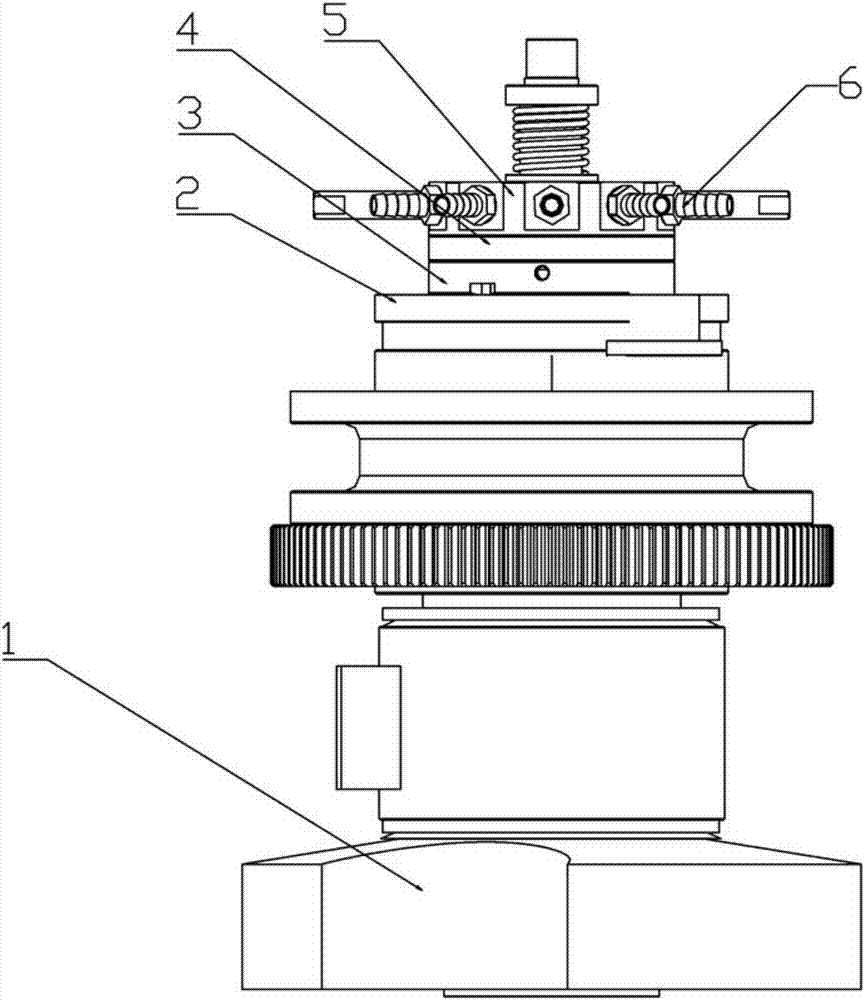

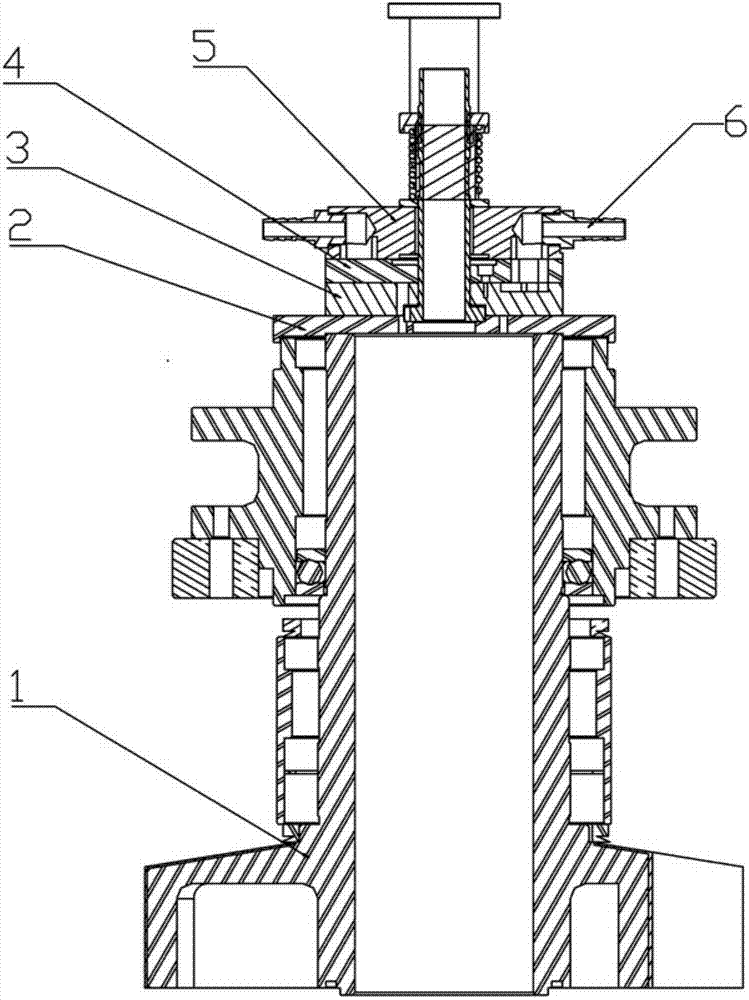

[0017] see Figure 1-2 , a food packaging machine vacuum chamber installation component gas distribution plate structure, has:

[0018] column;

[0019] The gas distribution base is fixedly installed on the upper end of the column;

[0020] The intermediate shaft is installed on the gas distribution base;

[0021] The gas distribution chassis, the gas distribution middle plate, and the gas distribution upper plate are stacked on the gas distribution base in sequence, and the gas distribution chassis, the gas distribution middle plate, and the gas distribution upper plate are rotatably set on the intermediate shaft; the gas distribution chassis, the gas distribution center There are air passages in the tray and the upper tray of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com