Underground pipe network mounting assisting device

A technology for installation assistance and underground pipe network, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of unfavorable sling service life and hoisting safety, etc., to improve hoisting safety, convenient connection or disconnection, Avoid flipping or slipping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

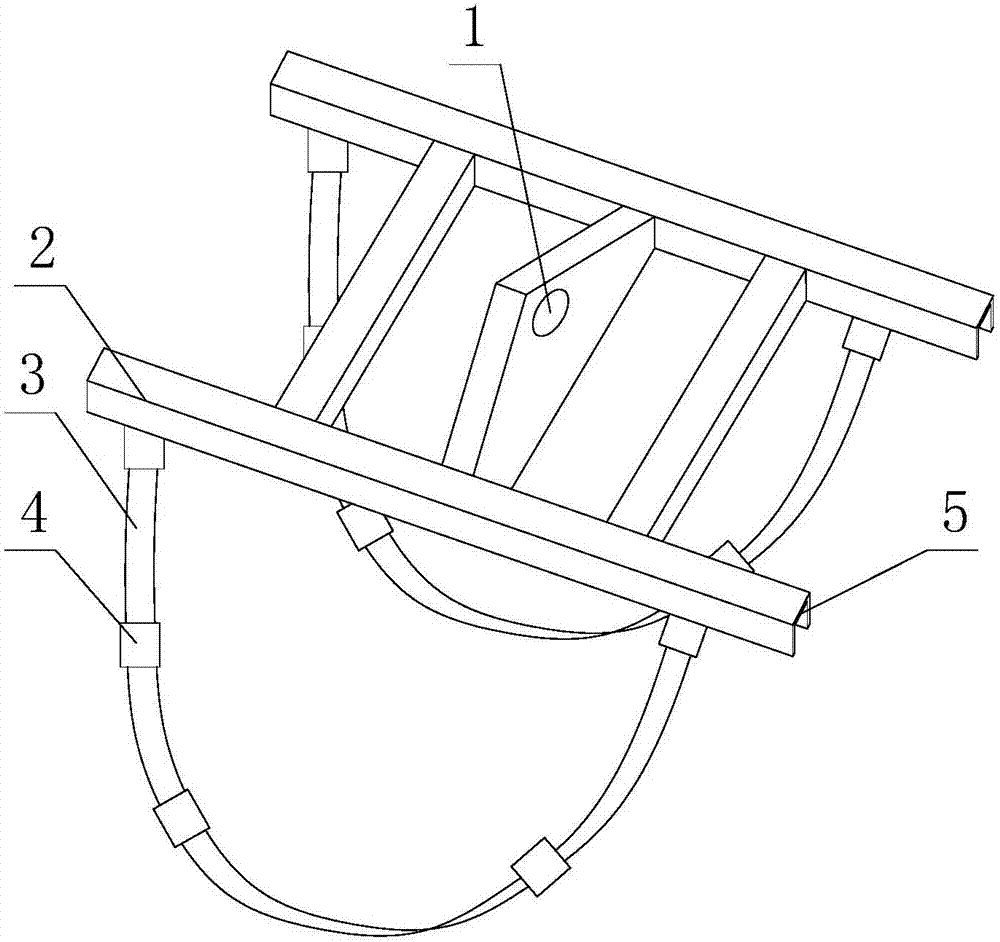

[0026] Such as figure 1 and figure 2 As shown, an auxiliary device for installing an underground pipe network includes a hanger 2, and also includes at least two ropes 3 fixed on the hanger 2, and each rope 3 has at least one end connected to the hanger 2. Disassemble the connection relationship, after the two ends of each rope 3 are fixedly connected with the hanger 2, the space surrounded by all the ropes 3 and the hanger 2 together constitutes the restraint space of the device for the pipe section;

[0027] Each rope 3 is connected in series by a plurality of rope segments in sequence, and the two connected rope segments are connected by a series device 4, and the connection relationship between each series device 4 and the corresponding two rope segments is a detachable connection relationship;

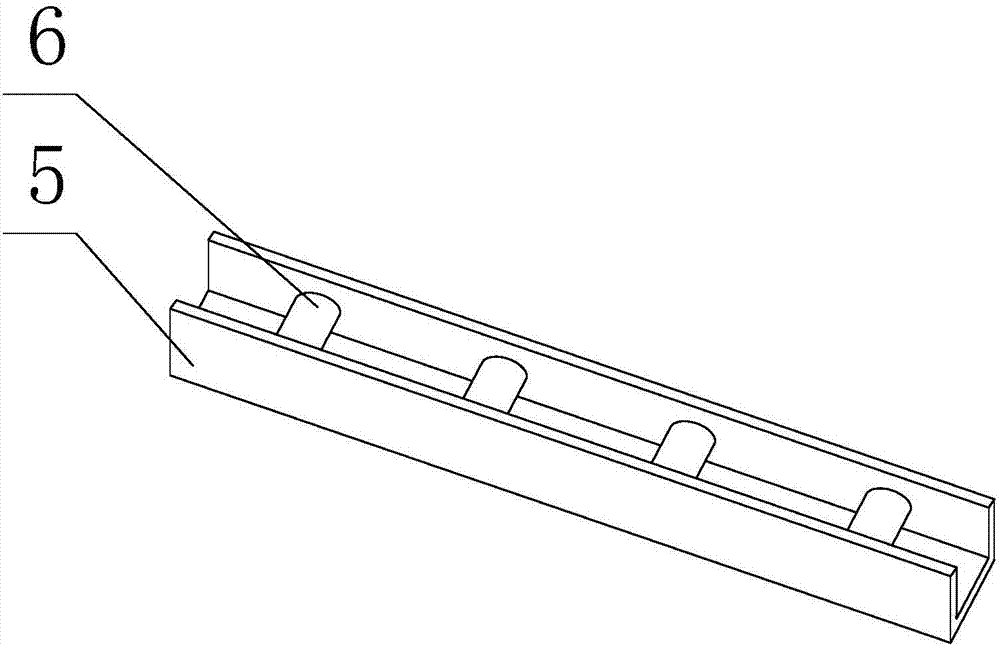

[0028] Described hanger 2 comprises the crossbar 5 that quantity is equal to number of rope 3, and described hanger 2 also comprises the connecting rod that is used to connect a...

Embodiment 2

[0033] Such as figure 1 and figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: as the specific structural realization and connection realization of both the rope 3 and the hanger 2, the ends of the detachable connection between each rope 3 and the hanger 2 The upper part is connected with the hanger 2 through a shackle, the cross bar 5 is a channel steel with the opening facing downward in the use state, and the fixing seat 6 is a circle with two ends fixedly connected with the inner sides of different side plates of the corresponding channel steel. Steel, and the end of each pocket rope 3 is all connected with round steel by shackle. The scheme is simple in structure and reliable in connection.

[0034] In order to make the device in use, the rope 3 can be completely separated from the hanger 2, so that when hoisting, the rope 3 can be pre-laid below the pipe section independently of the device, so that when using a crane for hoisting, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com