Direct reduction iron shaft furnace raw material tower harmful gas discharging and diffusing method

A technology of harmful gas and raw material tower, applied in shaft furnaces, furnaces, furnace types, etc., can solve problems such as fire, explosion, operator personal injury, etc., and achieve the effect of reducing work energy consumption, ensuring personal safety, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

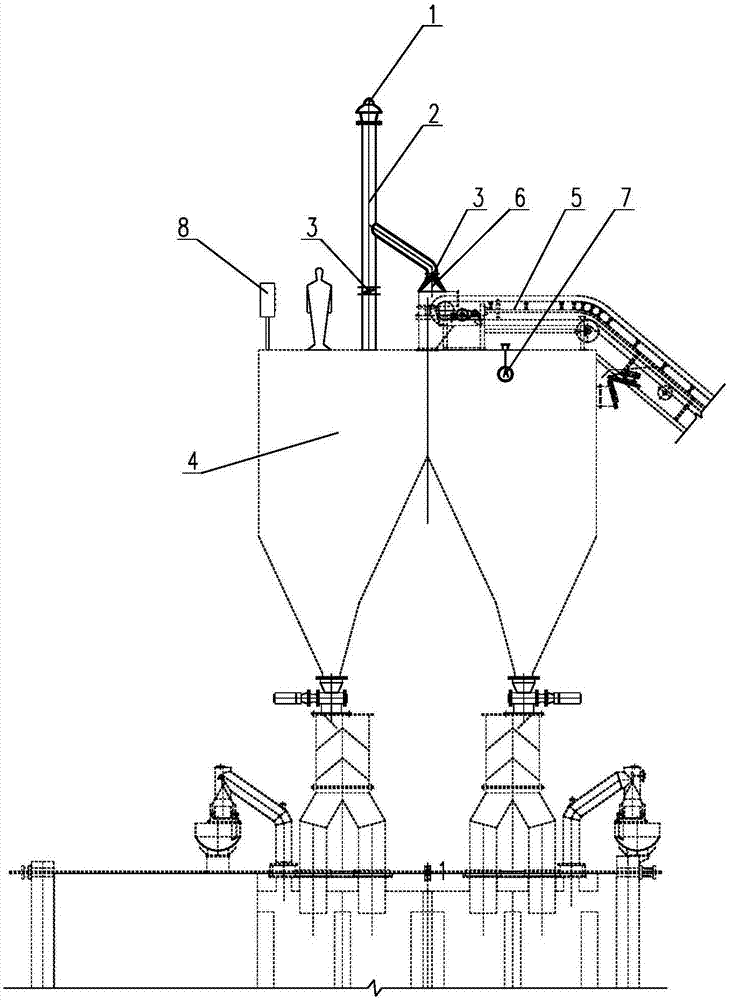

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as figure 1 , figure 2 Shown, a kind of direct reduction iron shaft furnace raw material tower harmful gas release method described in the present invention comprises the following steps:

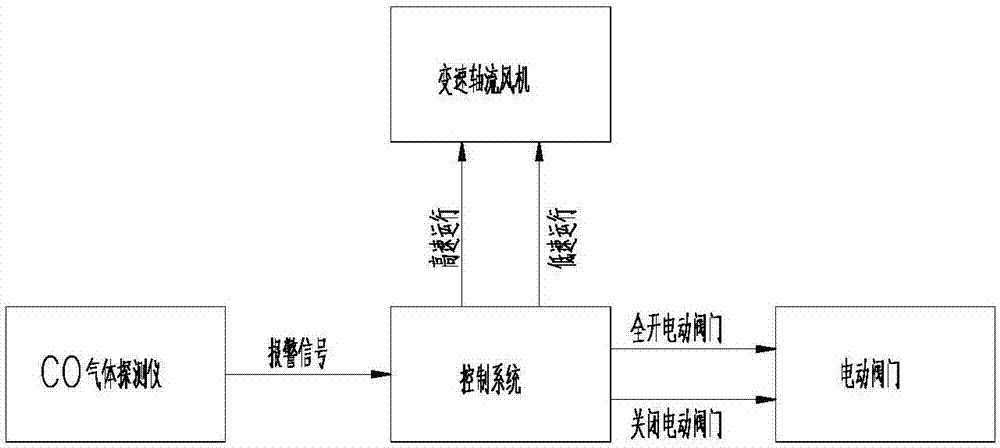

[0019] 1) When the direct reduction iron shaft furnace is in normal production, the CO gas detector 7 is used to detect the CO gas concentration inside the raw material tower 4, and the gas in the raw material tower 4 and the distribution device 5 at the top of the raw material tower is released through the harmful gas release pipe 2, which is harmful A variable-speed axial flow fan 1 is installed at the gas outlet of the upper part of the gas release pipeline 2, and the lower part is respectively connected to the ventilation hood 6 in the raw material tower 4 and on the top distribution device 5;

[0020] 2) When the monitored CO gas concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com