Anti-theft lock

A technology of locks and lock casings, applied in the field of locks, which can solve problems such as poor security, waste of effective travel of marbles, and reduction of lock key density, so as to achieve the effect of increasing density, preventing technical unlocking, and preventing violent opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

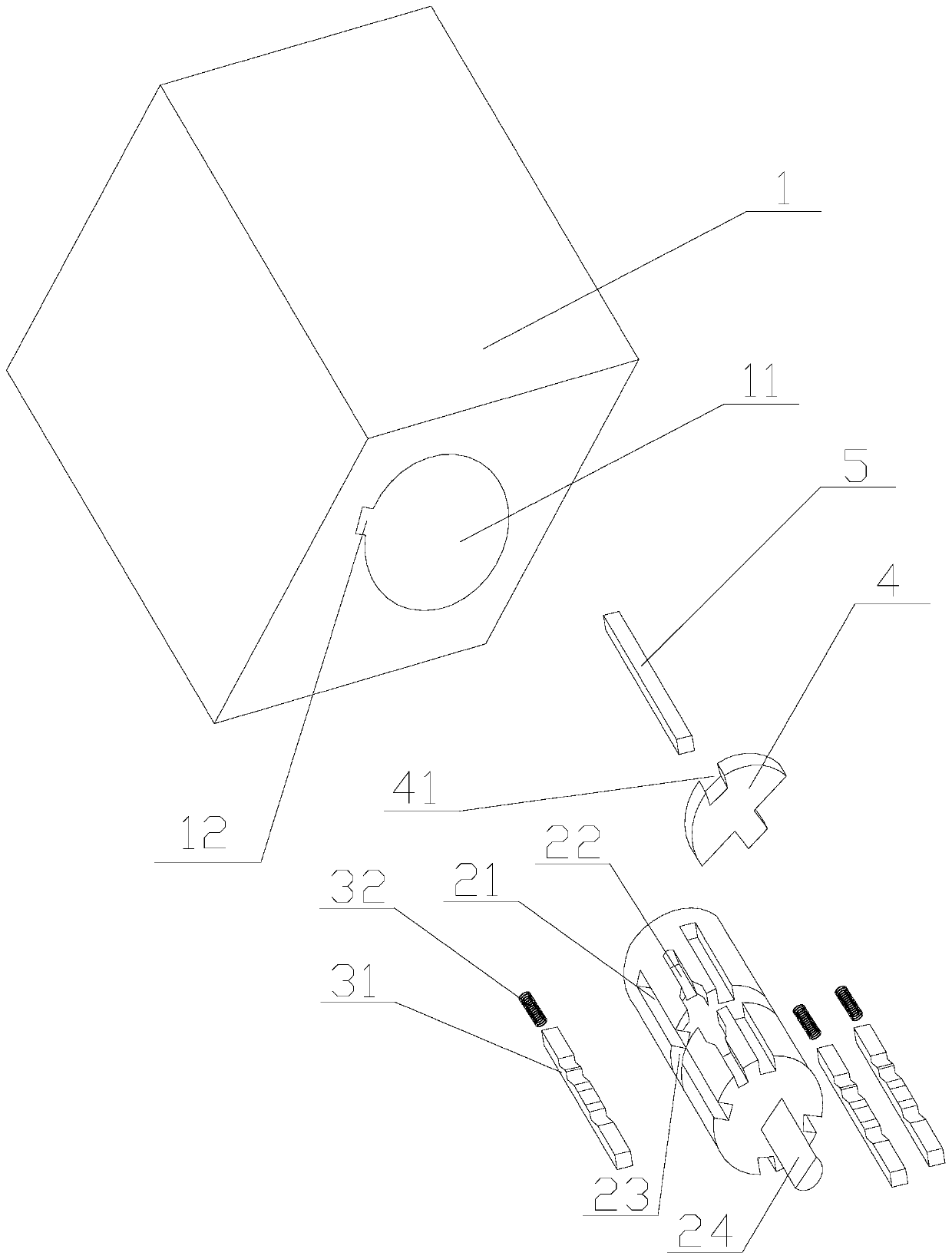

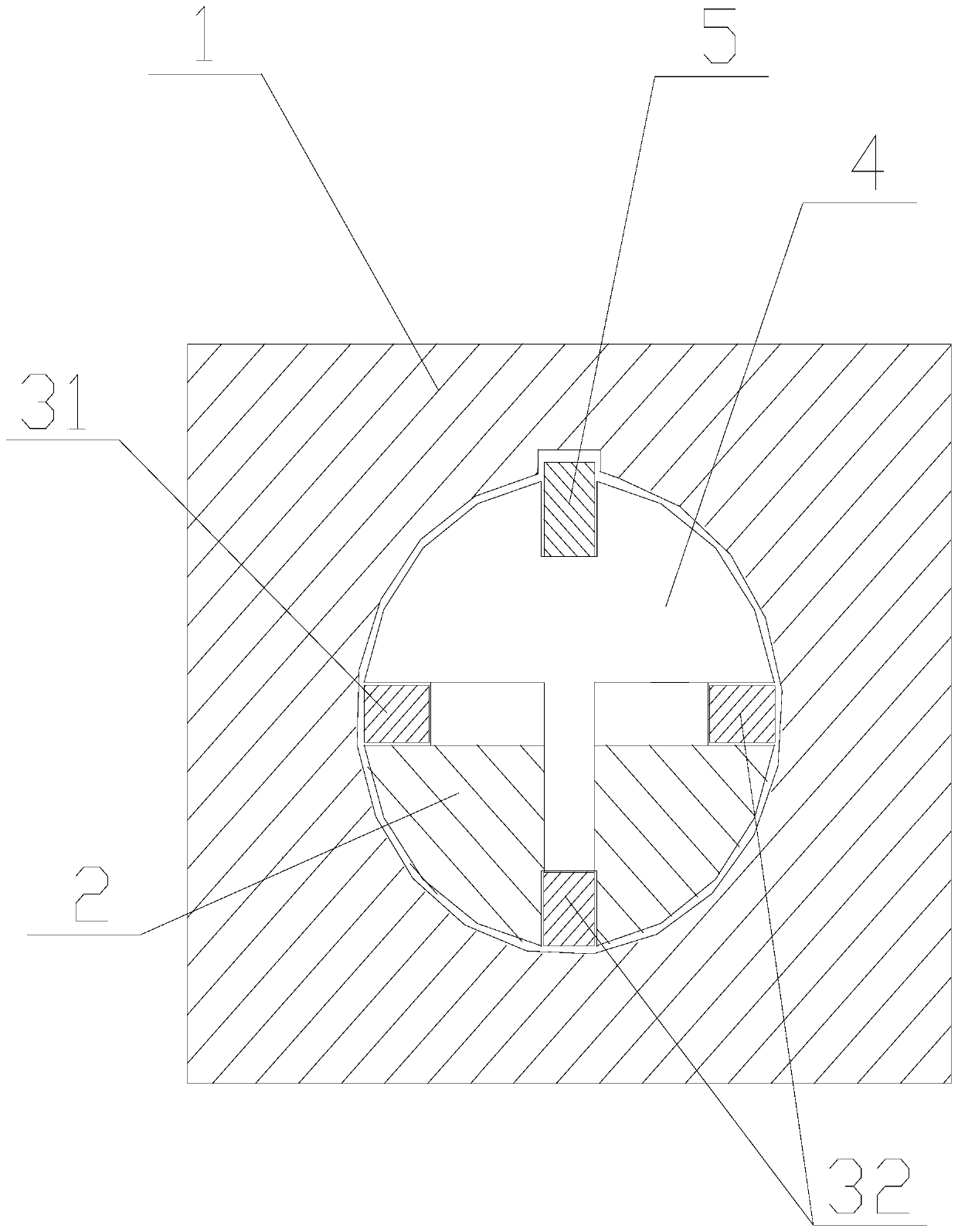

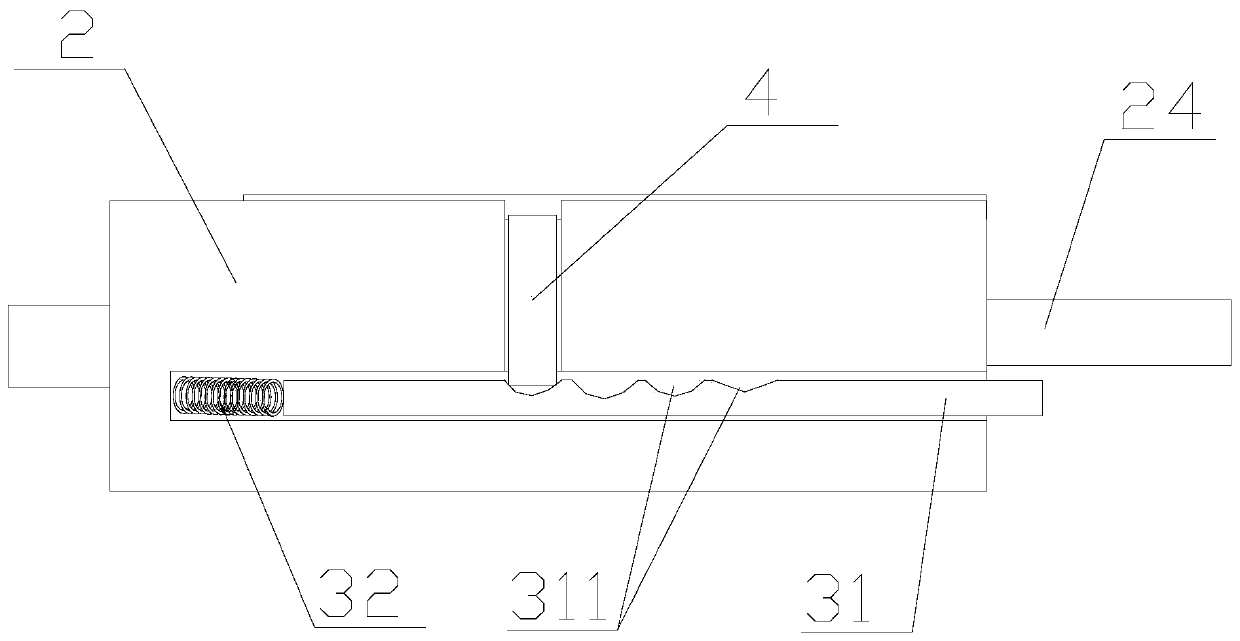

[0026] Figure 1 to Figure 3 An anti-theft lock according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a lock case 1 and a lock cylinder 2 .

[0027] Wherein, a lock housing hole 11 and a lock housing groove 12 are provided inside the lock housing 1 .

[0028] The lock case groove 12 is arranged on the side wall of the lock case hole 11 .

[0029] The lock core 2 is arranged in the lock case hole 11 and can rotate freely in the lock case hole 11 .

[0030] The side walls of the lock cylinder 2 are respectively provided with pin grooves 21 , lock bar grooves 22 and lock plate grooves 23 .

[0031] The lock cylinder 2 is generally provided with a plurality of pin grooves 21 .

[0032] For example, in this embodiment, the side wall of the lock cylinder 2 is provided with three pin grooves 21 .

[0033] A plurality of pin grooves 21 are respectively arranged axially along the lock cylinder 2 and the outer ends p...

Embodiment 2

[0058] Figure 4 and Figure 5 An anti-theft lock according to another embodiment of the present invention is schematically shown. As shown in the figure, the difference from Embodiment 1 is that a lock sleeve 6 is also included.

[0059] The lock sleeve 6 is provided with a lock sleeve hole 61 .

[0060] The lock sleeve 6 is arranged in the hole 11 of the lock case.

[0061] The lock core 2 is arranged in the lock sleeve hole 61 .

[0062] The side wall of the lock sleeve 6 is provided with a through lock pin hole 62 .

[0063] The locking pin 7 is disposed in the locking pin hole 62 .

[0064] When locking, the lock pin 7 enters the lock housing groove 12 to fix the position of the lock sleeve 6 and the lock housing 1, and the lock core 2 can rotate freely in the lock sleeve 6, thus forming a free-running lock.

[0065] In this embodiment, the thickness of the lock pin 7 is slightly greater than the depth of the lock pin hole 62. When locking, the inner end of the lock p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com