Hot air circulating furnace structure and assembly process thereof

A technology of hot air circulation and heating components, which is applied to lighting and heating equipment, partial agitation dryers, and dryers for static materials, etc. It can solve problems such as high cost, complex structure, and troublesome manufacturing and installation, and achieve high production efficiency. The effect of short process line and simple alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

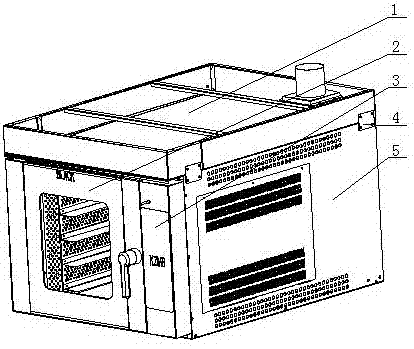

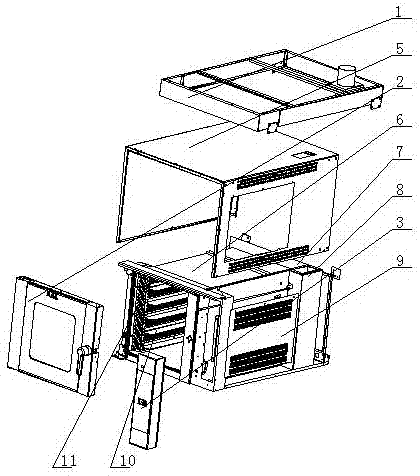

[0030] Such as figure 1 with figure 2 As shown, the structure of the hot air circulating furnace in this embodiment includes an inner box assembly 6, the rear end of the inner box assembly 6 is equipped with a heating assembly 7 and an exhaust assembly, the bottom of the inner box assembly 6 is a bottom plate, and one side of the inner box assembly 6 Electrical assembly 9 and exhaust pipe 8 are installed on the wall, and outer box board 5 is covered on the outside of inner box assembly 6. Furnace roof 1 is installed on the top of outer box board 5, and its front end is furnace door 2 and control panel assembly 3.

[0031] Outer bag board 5 becomes "┏┓" structure, and has a square hole on one side thereof.

[0032] There are air duct plates 11 on both sides of the inner box assembly 6, and a plurality of round holes are evenly opened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com