Self-discharge test method for lithium ion battery

A lithium-ion battery and testing method technology, which is applied in the field of self-discharge testing of lithium-ion batteries, can solve problems such as long medium-discharge time and complicated procedures, and achieve accurate self-discharge conditions and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

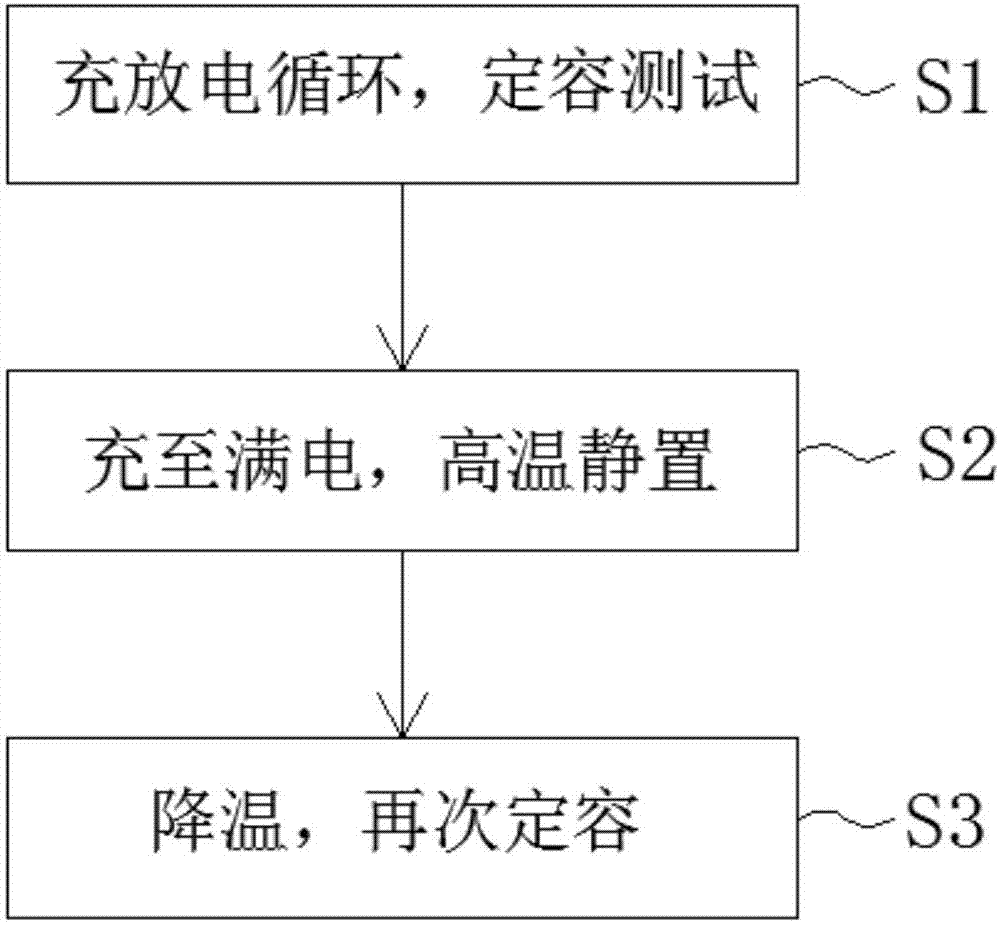

Method used

Image

Examples

Embodiment approach 1

[0032] Step S1: Randomly select 5 formed batteries with a rated capacity of 72Ah. First cycle the battery for 8 times. After the cycle is completed, adjust the battery to constant capacity. The cycle conditions are: in the constant capacity workshop (25±2°C) Under normal conditions, the charge-discharge cycle is carried out with a current of 1C; after the cycled battery is left to stand for 3 hours, the volume is constant. Discharge 0.5C to 2.5V, and then use 0.1C to discharge completely, that is to complete the constant volume.

[0033] Step S2: Charge the battery with a constant current of 0.5C to a fully charged state, then transfer the battery to a high-temperature room at 45°C, and store it for 7 days.

[0034] Step S3: Transfer the static battery to the constant volume room. After static for 8 hours, discharge the battery, then fully charge it, and constant volume. Refer to the second step for discharge conditions and constant volume conditions.

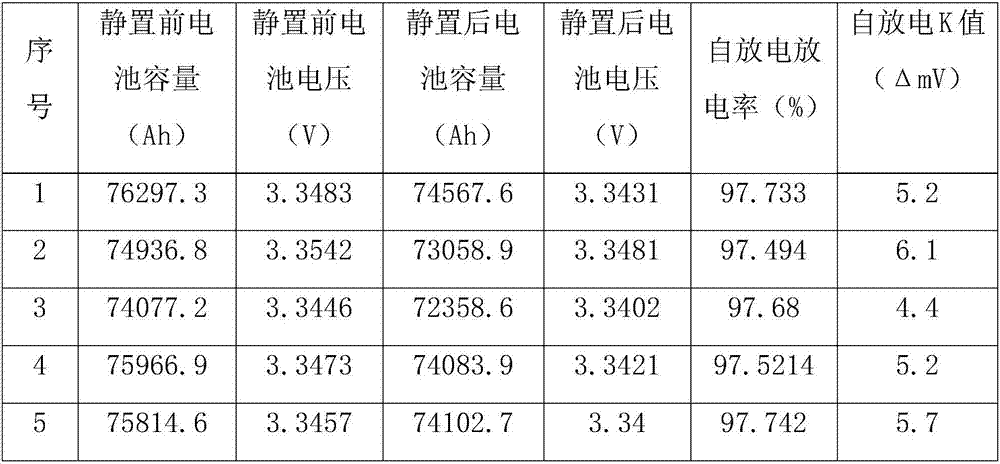

[0035] Table 1. Batter...

Embodiment approach 2

[0039] Step S1: Randomly select 5 formed batteries with a rated capacity of 72Ah. First cycle the battery 5 times. After the cycle is completed, constant the capacity of the battery. The cycle conditions are: in the constant capacity workshop (25±2°C) Under normal conditions, the charge-discharge cycle is carried out with a current of 1C; after the cycled battery is left to stand for 3 hours, the volume is constant. Discharge 0.5C to 2.5V, and then use 0.1C to discharge completely, that is to complete the constant volume.

[0040] Step S2: Charge the battery with a constant current of 0.1C to a fully charged state, then transfer the battery to a high temperature room at 45°C, and store it for 10 days.

[0041] Step S3: Transfer the static battery to the constant volume room. After static for 8 hours, discharge the battery, then fully charge it, and constant volume. Refer to the second step for discharge conditions and constant volume conditions.

[0042] Table 2. Battery self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com