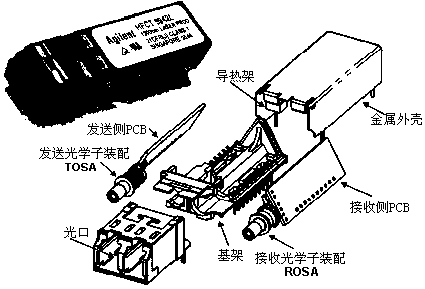

SIP packaging structure with integrated photoelectric transceiver function and manufacturing method thereof

A technology of optoelectronic transceiver and packaging structure, applied in the coupling of optical waveguides, etc., can solve the problems of poor resistance to external force, low production efficiency, and many processes, so as to enhance the ability to resist external force, improve production efficiency, and avoid water vapor corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

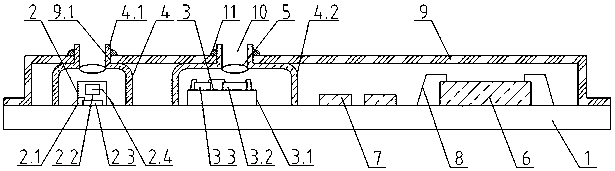

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

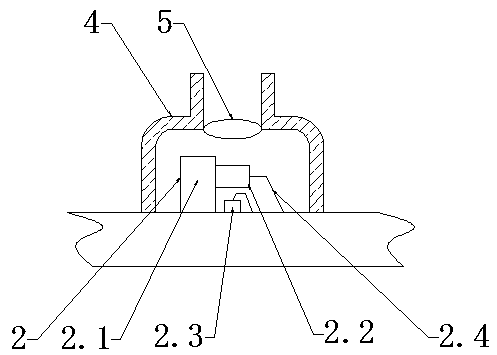

[0047] Such as figure 2 , image 3 As shown, a SiP packaging structure with integrated photoelectric transceiver function in this embodiment includes a substrate 1 on which an optical transmitter 2 and an optical receiver 3 are mounted, and the optical transmitter 2 includes a first A copper block 2.1, a laser 2.2 is mounted on the side of the first copper block 2.1, a backlight tube 2.3 is mounted on the substrate 1 below the laser 2.2, and the backlight tube 2.3 and the laser 2.2 are connected by a first metal wire 2.4 To the substrate 1, the optical receiver 3 includes a second copper block 3.1, a detector 3.2 and a pre-amplifier IC3.3 are mounted on the second copper block 3.1, and the connection between the detector 3.2 and the pre-amplifier IC3.3 between the detector 3.2 and the second copper block 3.1, and between the preamplifier IC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com