A method for detecting the movement position and posture of the end of the hybrid automobile electrophoretic coating conveying mechanism

A technology of conveying mechanism and electrophoretic coating, which is applied in the direction of measuring device, surveying and navigation, computer parts, etc., which can solve the problem of difficult accurate detection, low accuracy of detection of motion position and posture at the end of the mechanism, and the characteristic points of the connecting rod at the end of the complex mechanism. It is difficult to extract and other problems to achieve the effect of ensuring rapidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

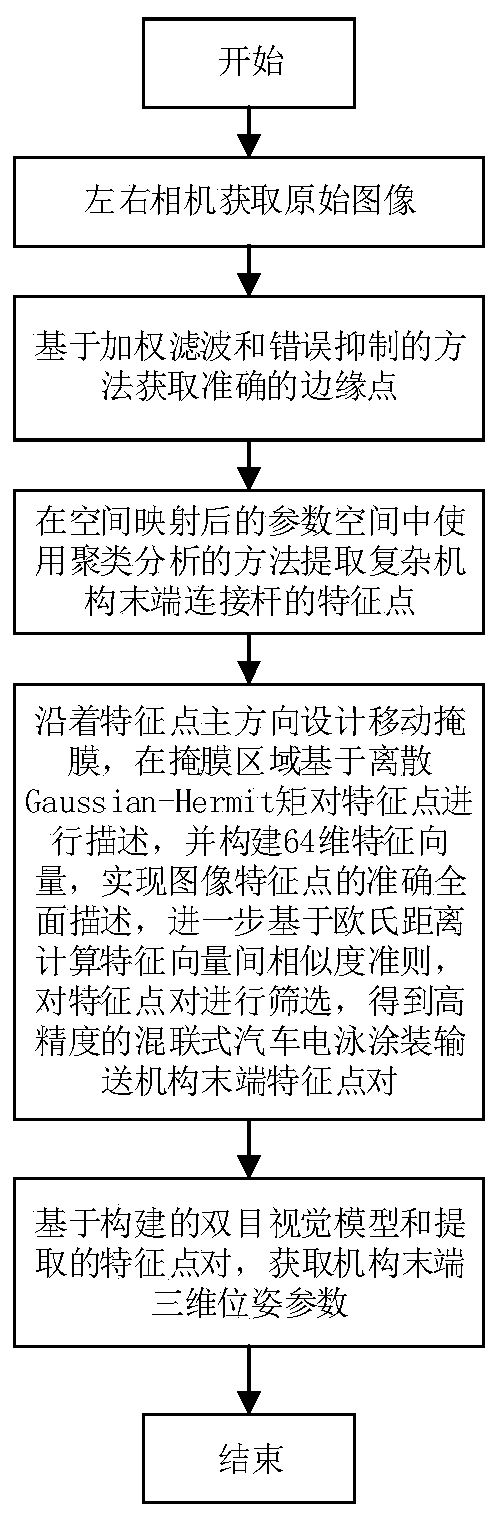

[0095] The present invention emphatically proposes a method for detecting the movement position and posture of the end of the hybrid automobile electrophoretic coating conveying mechanism, which solves the problem of light interference in the working environment, blurred boundaries between mechanism components, and occlusion during the operation of the hybrid automobile electrophoretic coating conveying mechanism. The problem that the end of the mechanism based on vision is difficult to detect and the detection accuracy is not high caused by these factors.

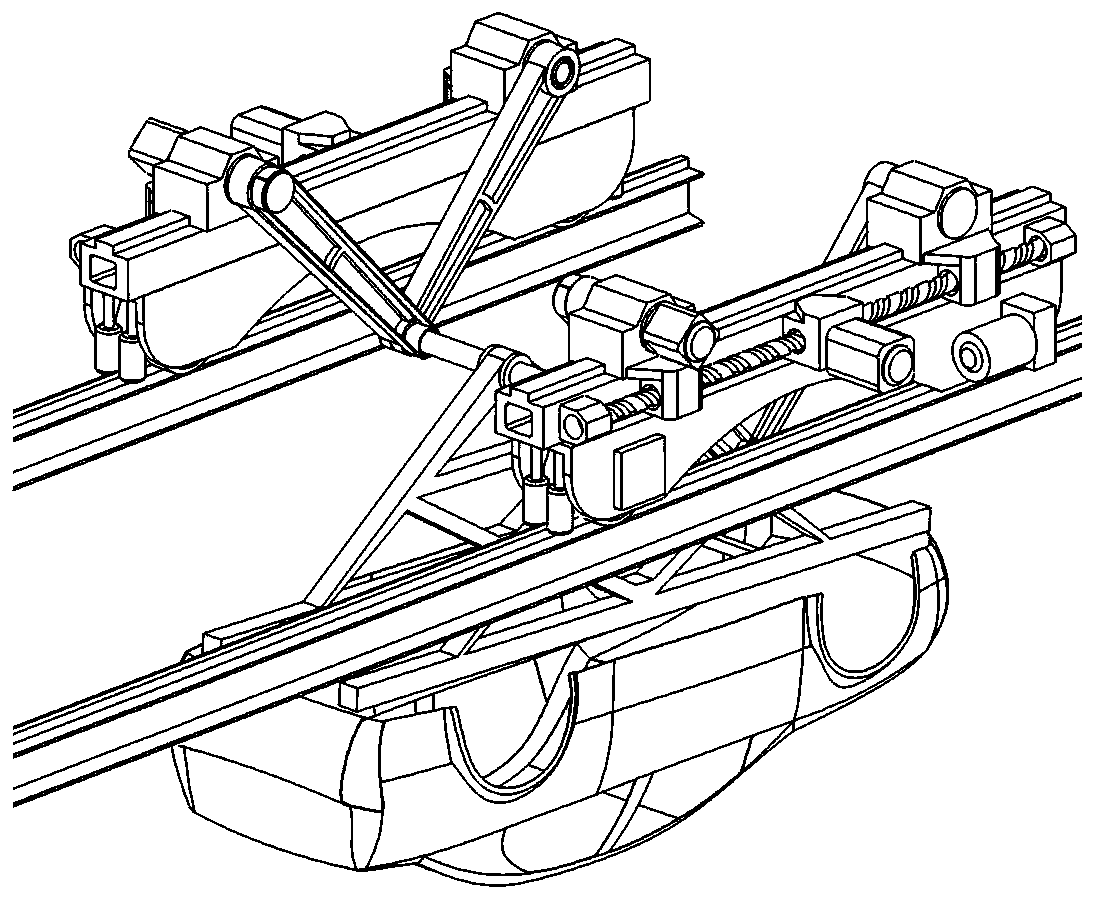

[0096] Specific embodiments are described by taking the new hybrid automobile electrophoretic coating conveying mechanism developed by our research group as the detection object, and its specific implementation methods are as follows:

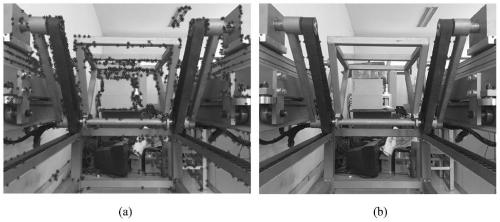

[0097] 1. Collect the original image of the conveying mechanism. The image of the new type hybrid electrophoretic coating conveying mechanism is collected by a binocular camera. The camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com