Peanut automatic carefully chosen based gynophore removal adaptive matching control system and method

A technology of adaptive matching and control method, applied in application, food science, food processing and other directions, can solve the problems of low classification efficiency and poor quality, and achieve the effect of improving quality, ensuring reliability, and realizing intelligence and informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

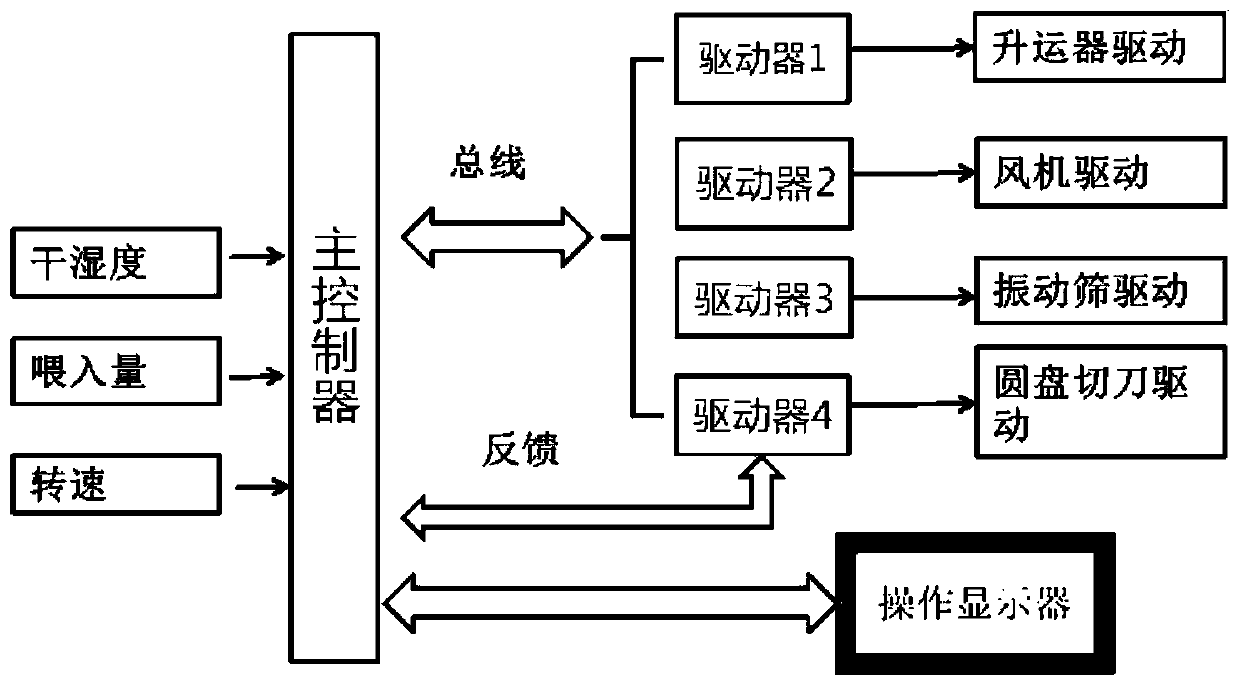

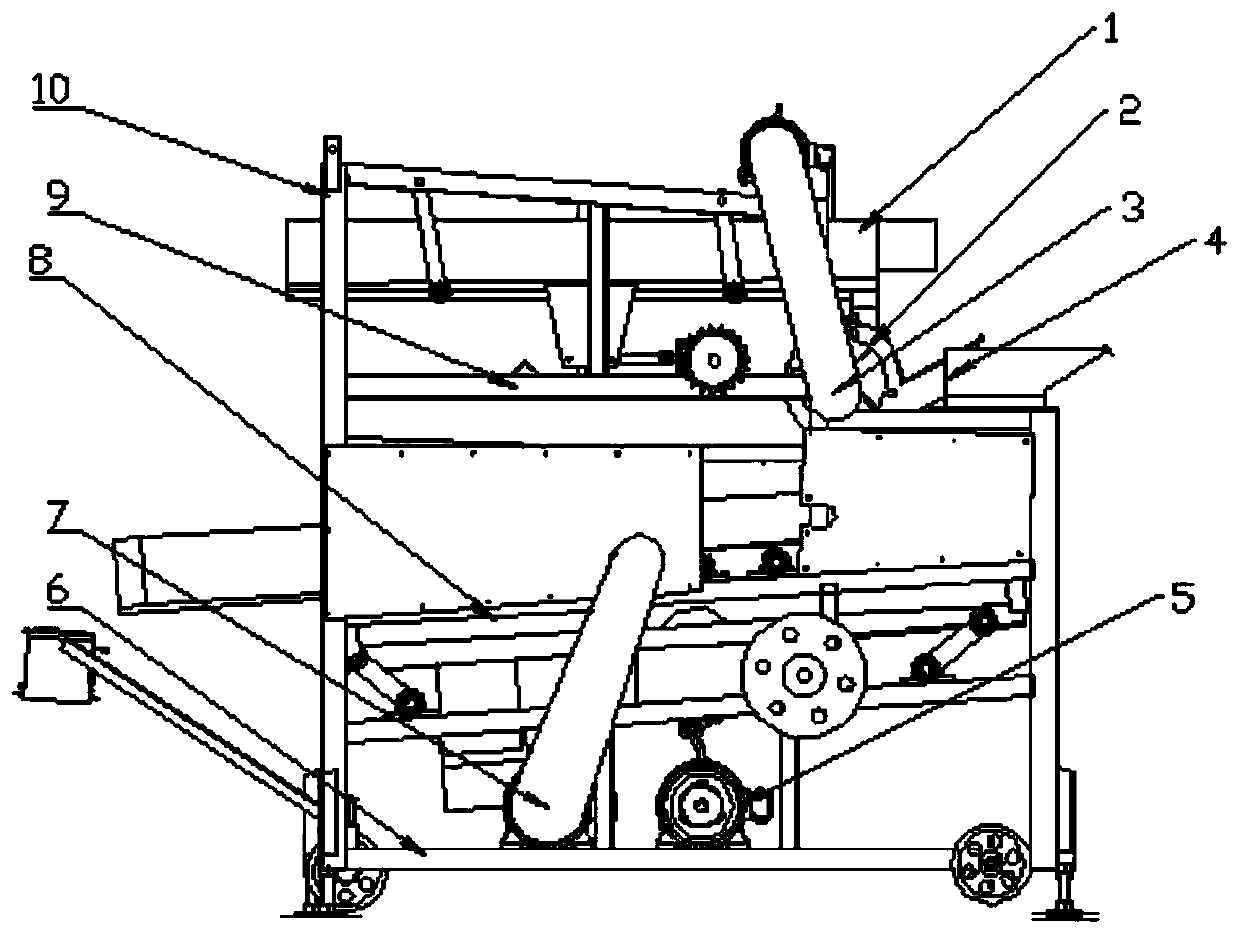

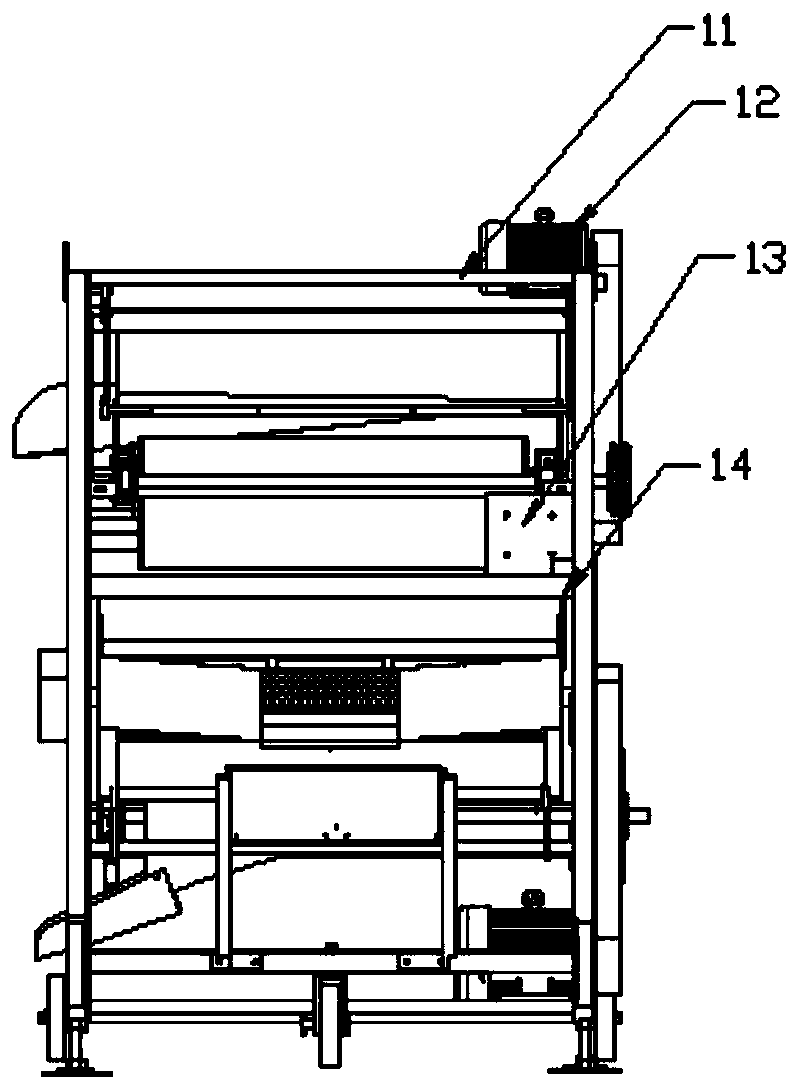

[0069] Embodiment 1. A self-adaptive matching control system for removal of ovary stalks based on automatic selection of peanuts, based on the size of the feeding amount of the peanut selection mechanism and the dry humidity to regulate the operating frequency of the motors of each part of the machine to achieve the best automatic selection. Adapt to the control state, the block diagram is as follows figure 1 As shown, including main controller, elevator motor and elevator motor driver, fan and fan driver, vibrating screen motor and vibrating screen motor driver, disc cutter motor and disc cutter motor driver (disc The cutter group is used to cut the peanut ovary stalk), the motor driver of the elevator, the fan driver, the motor driver of the vibrating screen and the motor driver of the disc cutter group are all electrically connected with the main controller, the structure diagram of the peanut selection mechanism Such as Figure 2-4 As shown, it is also provided with a dry...

Embodiment 2

[0071] Embodiment 2, based on the control system proposed in Embodiment 1, the specific adaptive matching process based on the data collected by each sensor is realized in the following manner:

[0072] 1. Data extraction:

[0073] 1. Feed amount information extraction:

[0074] The second stress sensor detects the amount of peanut feeding and transmits the stress data to the main controller. After filtering and vibration elimination, the voltage signal reflects the stress, and the motor speed is controlled by adjusting the operating frequency according to the voltage.

[0075] When determining the actual feeding amount information, the stress sensor data whose value is in an abnormal state is first eliminated according to the specific working condition type. When determining the weight corresponding to each stress sensor, the actual value of the stress sensor is arranged in descending order. And the weight distribution is carried out according to the number of effective sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com