Elevator system

A technology of equipment and elevators, applied in elevators, transportation and packaging, etc., can solve the problems of not being able to know the damage of the bearing mechanism, achieve the effect of reducing the current intensity or voltage, and simplifying the monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

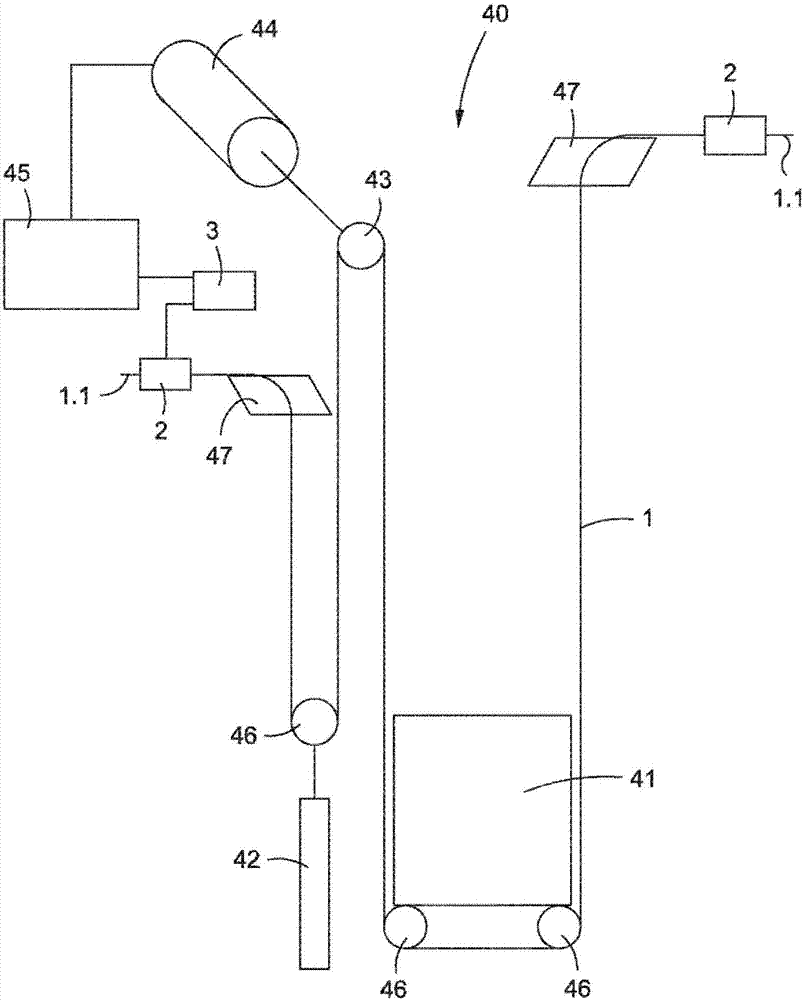

[0032] exist figure 1 The elevator installation 40 , shown in an exemplary and schematic manner, comprises an elevator car 41 , a counterweight 42 as well as a support mechanism 1 and a drive pulley 43 with an associated drive motor 44 . The drive pulley 43 drives the supporting mechanism 1 and thereby moves the elevator car 41 in the opposite direction to the counterweight 42 . The drive motor 44 is controlled by an elevator control 45 . The car 41 is designed to load and transport people or goods between floors of a building. The car 41 and the counterweight 42 are guided along guide means (not shown). In this example, the car 41 and the counterweight 42 are respectively suspended on carrying rollers 46 . In this case, the support means 1 is fixedly arranged on the first support means fastening device 47 and is then firstly guided around the support rollers 46 of the counterweight 42 . The carrier 1 is then placed on the drive pulley 43 in order to guide the carrier roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com