Urea manufacturing method

A manufacturing method and technology of urea, applied in the field of urea manufacturing, capable of solving problems such as processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

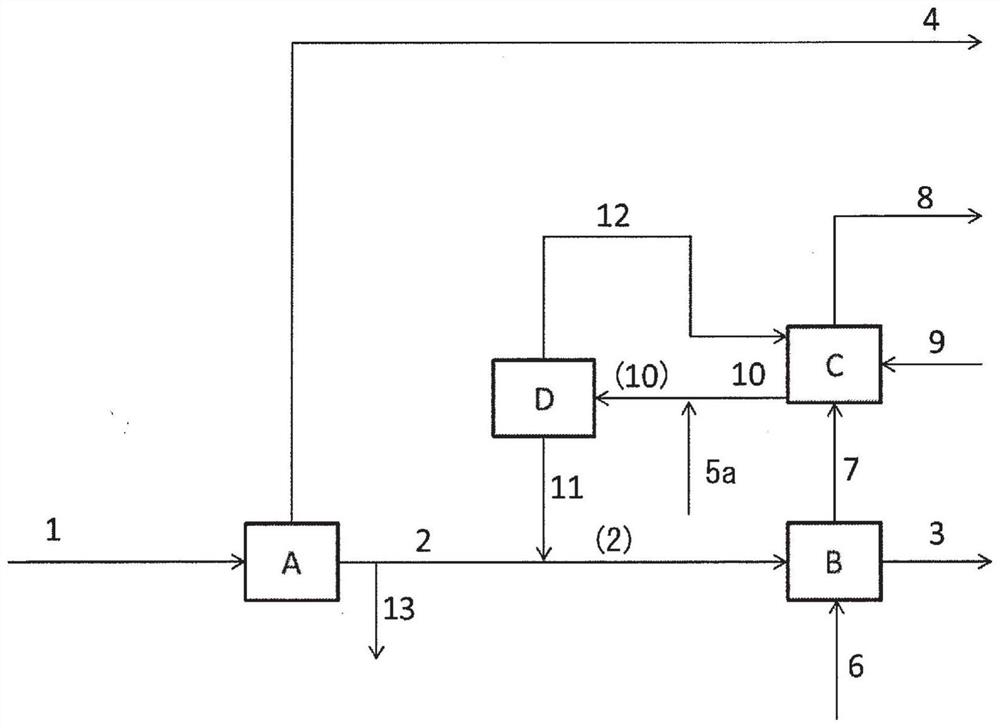

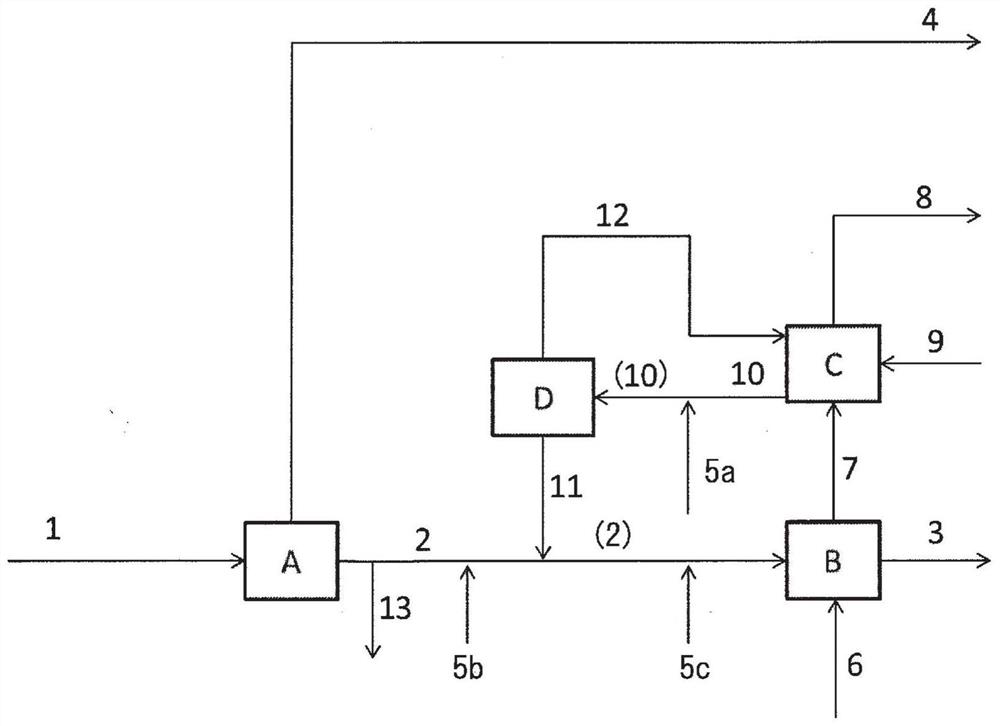

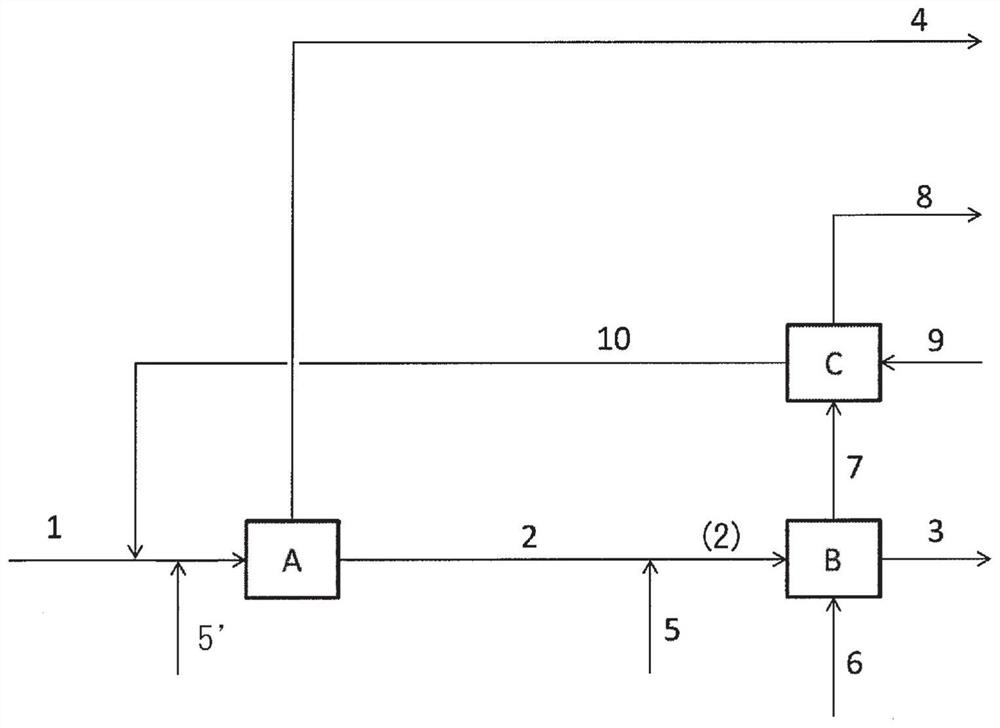

[0046] Then, for figure 1 For the implementation of the method, a specific study was carried out with reference to the material balance in each line. Here, assuming a urea plant equipped with a fluidized and spouted bed type urea granulation device with a production capacity of 3,500 tons / day of solid urea, the calculation is based on figure 1 (Example), image 3 The flow of (Comparative Example) is an approximate value of the material balance of each line. figure 1 In the calculation in the embodiment, the concentrated urea solution of line 13 was not taken out. in addition, image 3 In the comparative example, the additive was added from line 5. First, the example ( figure 1 ) The material balance of each line in ) is shown in Table 1, the comparative example ( image 3 ) The material balance of each line in ) is shown in Table 2.

[0047] [Table 1]

[0048]

[0049] (2)...Line 2 after converging with Line 11

[0050] (10)...line 10 after additive addition (line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com