Method for manufacturing printed products

A technology for printed matter and printing materials, which is applied in the field of manufacturing printed matter and can solve problems such as gloss differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

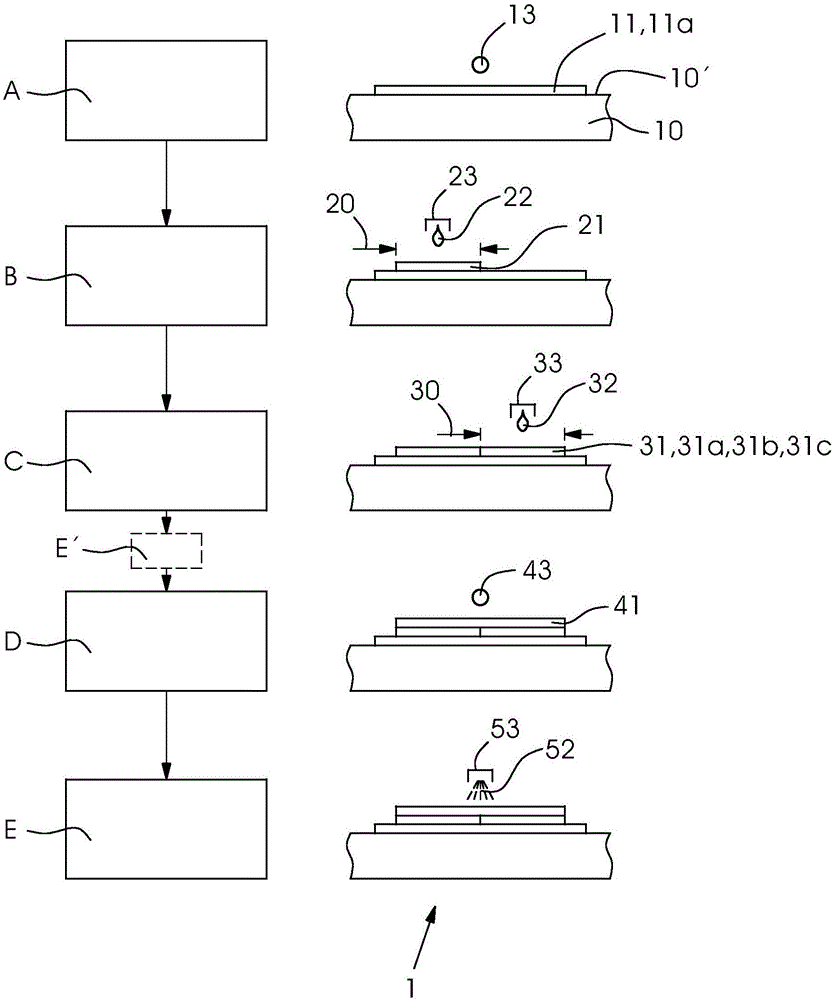

[0029] figure 1 The method steps A to E or E′ of a preferred embodiment of the method according to the invention are schematically shown in a flow diagram. In addition to the individual method steps, it is likewise shown schematically which device technical measures can be used in each case and how the printed matter can be produced in sequence.

[0030] In method step A, first a printing material 10 with a surface 10 ′ is provided. The printing material 10 can be a sheet or a web. The printing material 10 can be made of paper, cardboard or synthetic material. A coating 11 is applied to the printing substrate 10 , comprising an acid 11 a. The coating 11 can be applied, for example, by means of a roller 13 . As an alternative to method step A, provision can also be made to provide a printing substrate which has already been coated with an acid layer.

[0031] In method step B, the printing material 10 or its surface 10 ′ is printed with a water-based ink 21 in the image re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com