Low-dielectric constant high-quality factor LTCC microwave medium material and preparation method thereof

A technology of microwave dielectric material and high quality factor, which is applied in the field of low dielectric high quality factor LTCC microwave dielectric material and its preparation, can solve the problem of high sintering temperature, weak aggregation and recrystallization ability of magnesium aluminum spinel, and high sintering temperature and other problems, to achieve the effect of simple process, good microwave dielectric properties, and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

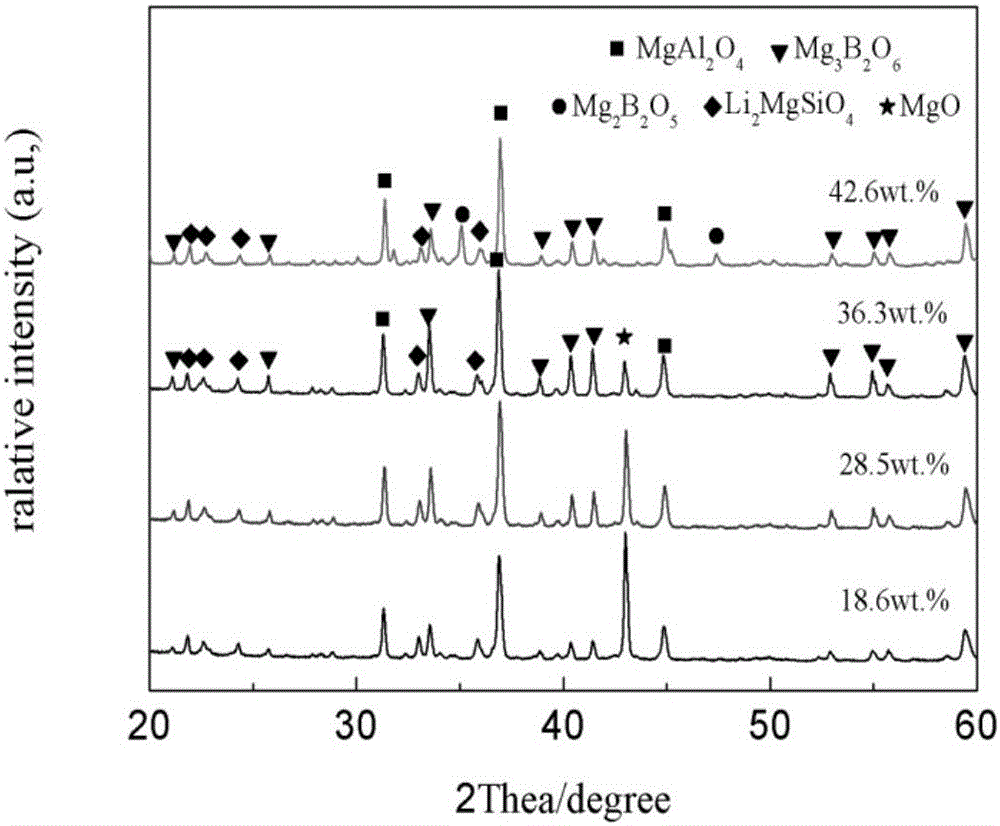

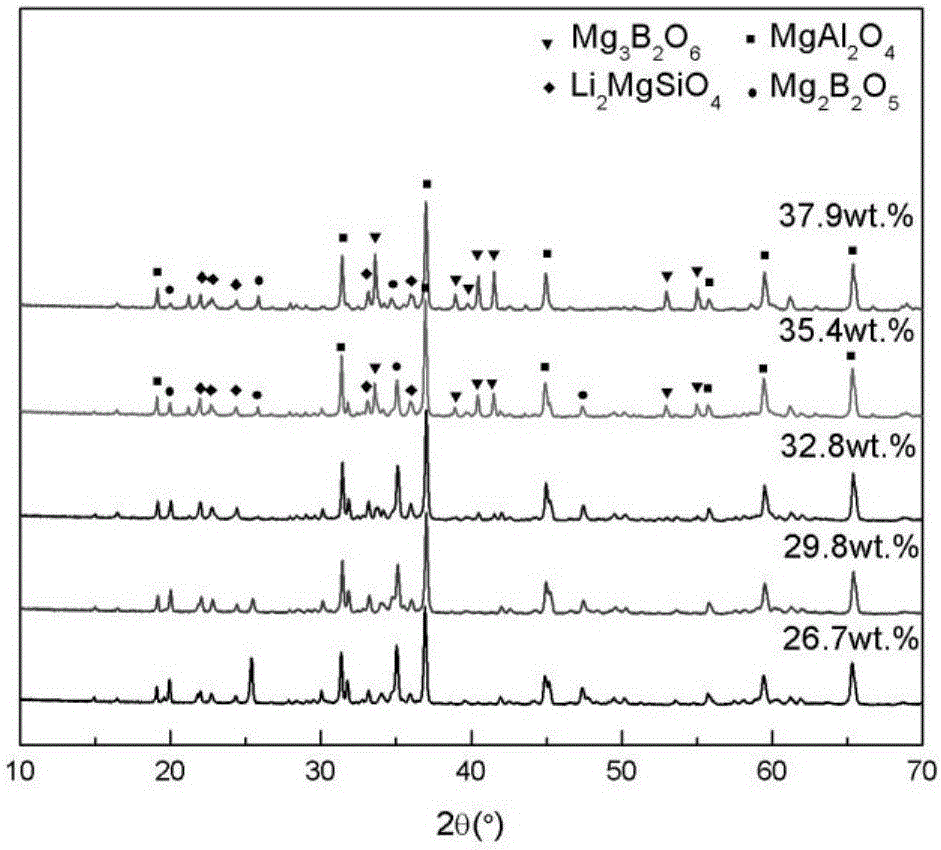

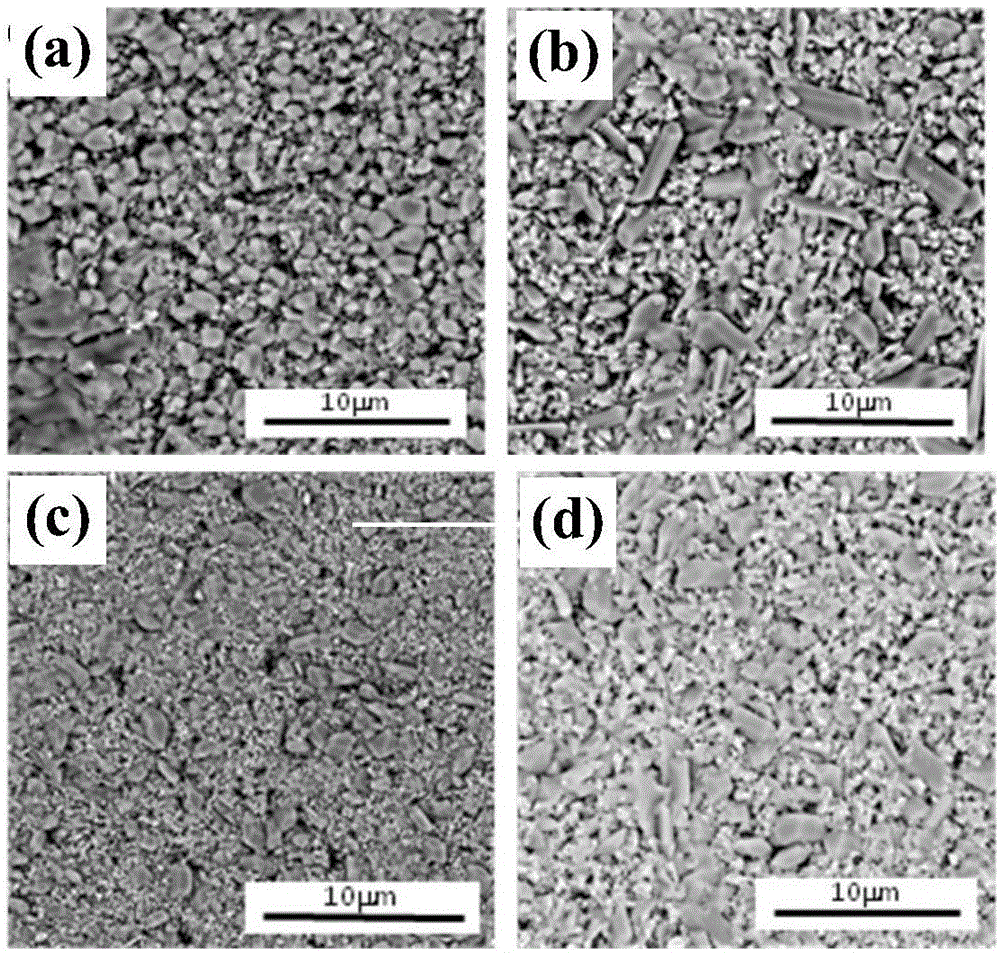

[0027] A low dielectric high quality factor LTCC microwave dielectric material including MgAl 2 o 4 Ceramic and MgAl 2 o 4 Ceramic composite fever reducer, the MgAl 2 o 4 Ceramics are made of MgO, Al 2 o 3 Formed after pre-burning; the composite fever reducer is composed of Li 2 CO 3 、H 3 BO 3 , SiO 2 , ZnO, and MgO are calcined to form Li 2 O-MgO-ZnO-B 2 o 3 -SiO 2 For glass, the mass percentages of each raw material in the composite fever reducer before calcining are: Li 2 CO 3 8.9wt.%-14.2wt.%, H 3 BO 3 18.6wt.%-44.5wt.%, SiO 2 8.3wt.%-13.3wt.%, ZnO 7.2wt.%-11.6wt.%, MgO 26.7wt.%-42.3wt.%; 2 o 4 Ceramics and pre-fired Li 2 O-MgO-ZnO-B 2 o 3 -SiO 2 The glass is mixed by ball milling at a mass ratio of 1:2, granulated, shaped, debinding and sintered to make the final LTCC microwave dielectric material with low order and high quality factor.

[0028] The preparation method of the above-mentioned microwave dielectric material comprises the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com