Self-resetting steel framework

A self-resetting, steel frame technology, which is applied in basic structural engineering, building components, building types, etc., can solve the problems of poor self-resetting ability, cannot be repaired automatically, weak seismic performance, etc., and achieves easy construction, convenient connection, and increased consumption. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

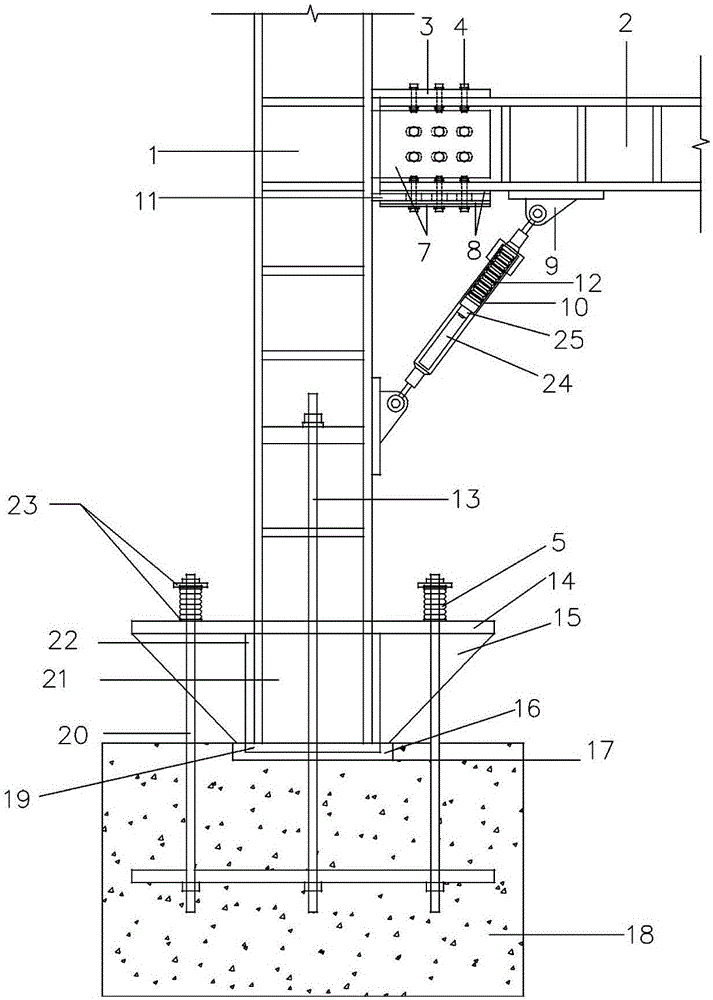

[0042] Such as Figure 1-3 As shown, the present invention provides a self-resetting steel frame, including a steel frame column 1, a steel frame beam 2, a self-resetting column foot and a self-resetting beam-column frictional energy-dissipating node, one end of the self-resetting column foot is connected to the foundation 18, and the The other end of the reset column foot is connected to one end of the steel frame column 1, and the other end of the steel frame column 1 is connected to the steel frame beam 2 through a self-resetting beam-column frictional energy dissipation node.

[0043] The self-resetting column foot includes a base plate 19, a cantilevered plate 14 and a support plate 15. A through hole is provided in the middle of the cantilevered plate 14, and the steel frame column 1 is placed on the base plate 19, the support plate 15 and the cantilevered plate through the through hole. 14, and placed in the limiting groove 17 of the foundation 18 with the bottom plate ...

Embodiment 2

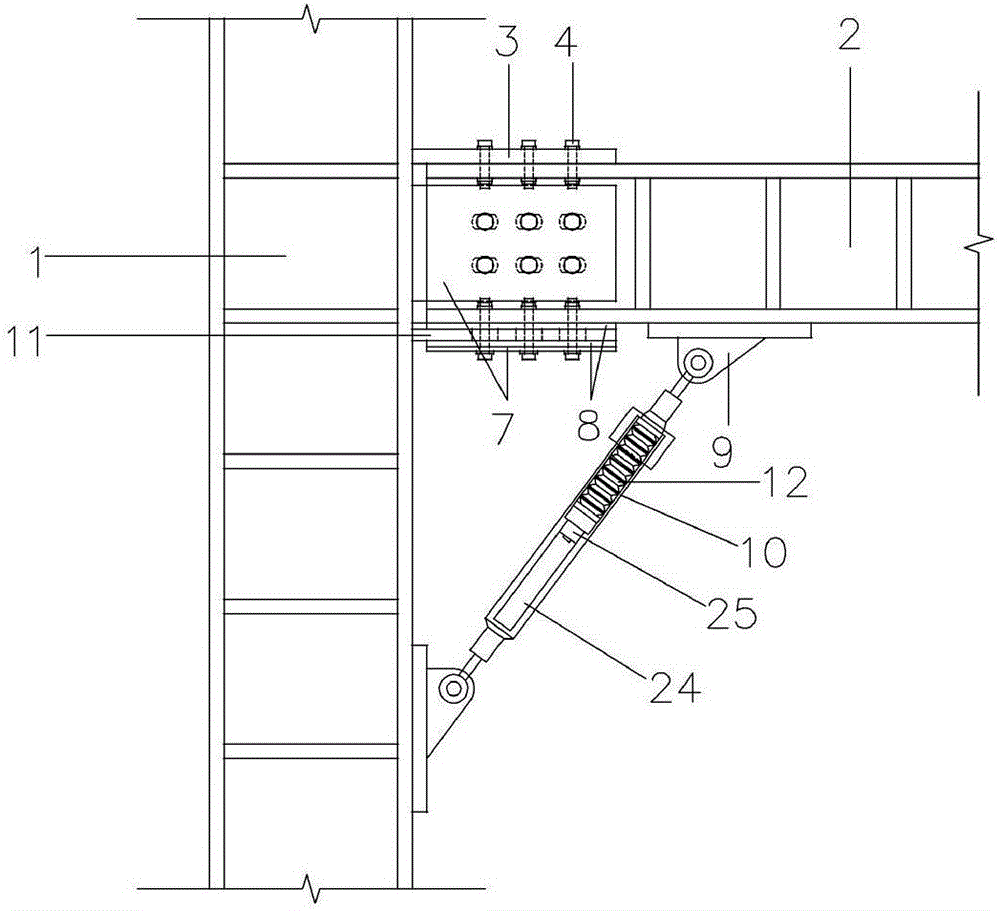

[0051] Such as Figure 4-5 As shown, a friction backing plate 8 is provided between the contact surface of the upper flange plate 3 and the steel frame beam 2, and a friction backing plate 8 is also provided between the contact surface of the upper flange plate 3 and the head of the high-strength bolt 4; A steel plate 7 is arranged between the plane where the friction pad 8 contacts the head of the high-strength bolt 4 . The connection position between the lower flange plate 11 and the steel frame beam 2 is not provided with a friction backing plate 8, and other parts are the same as in the first embodiment.

Embodiment 3

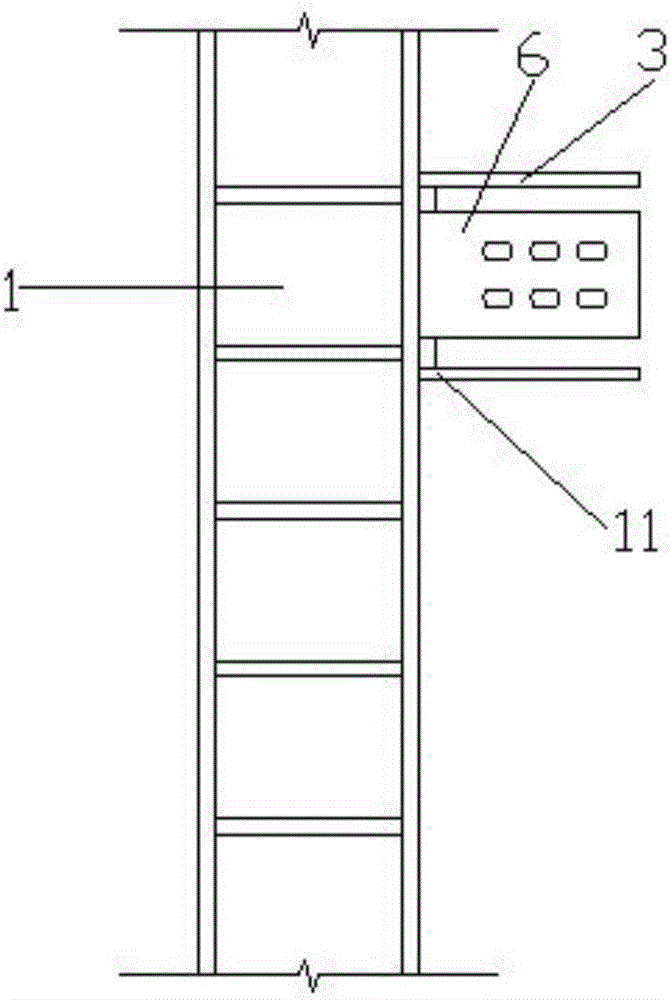

[0053] Such as Figure 6-7 As shown, the flange stiffener 22 is located inside the flange of the steel frame column 1 . Other parts are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com