Electric control cabinet assembly and air conditioner system

An air-conditioning system and electric control box technology, applied in heating and ventilation control systems, heating and ventilation safety systems, lighting and heating equipment, etc., can solve the reliability and service life of electrical components, safety hazards, heat dissipation efficiency reduction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

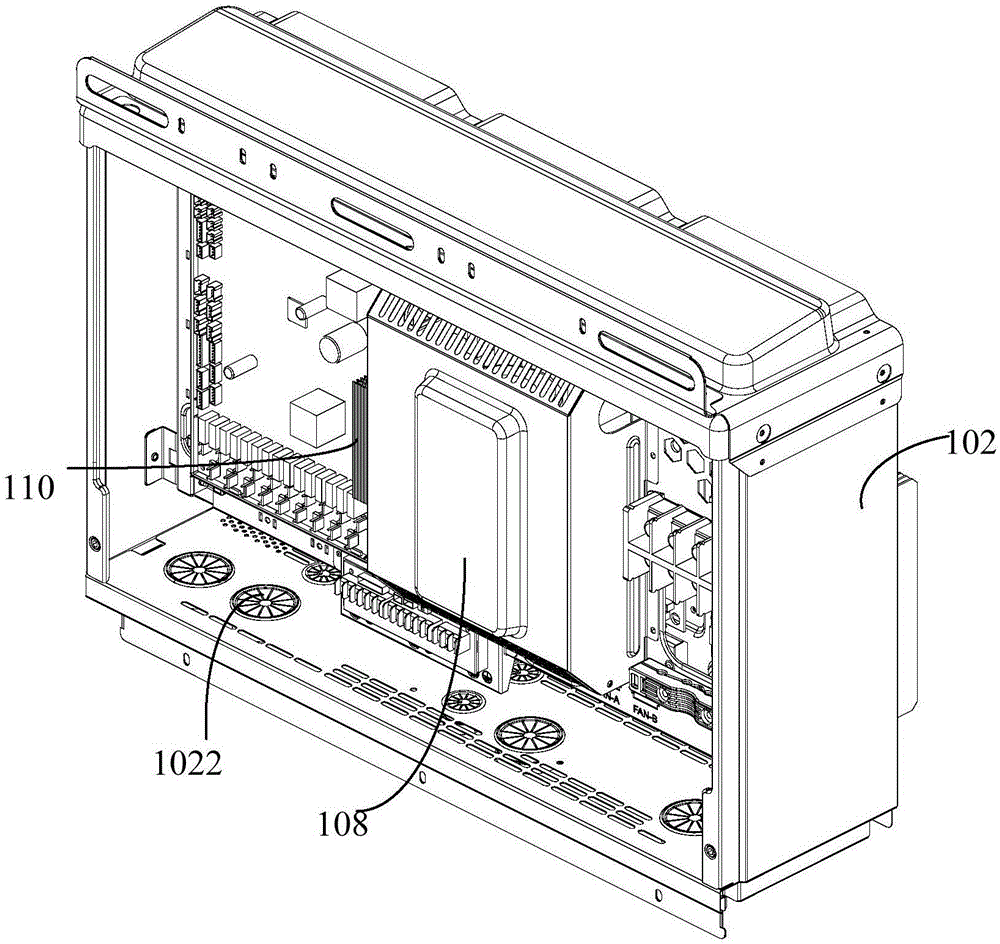

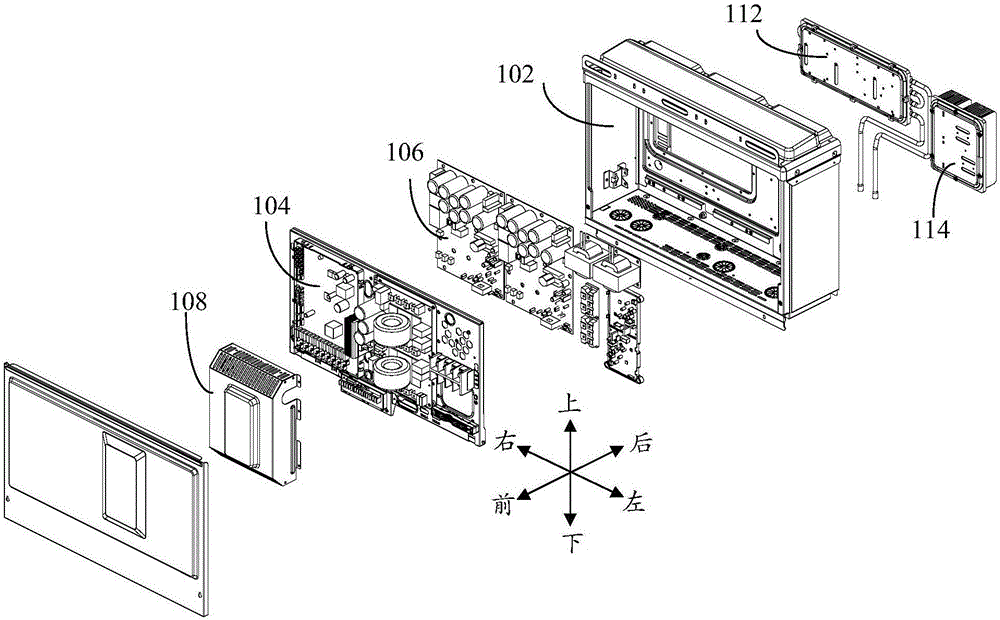

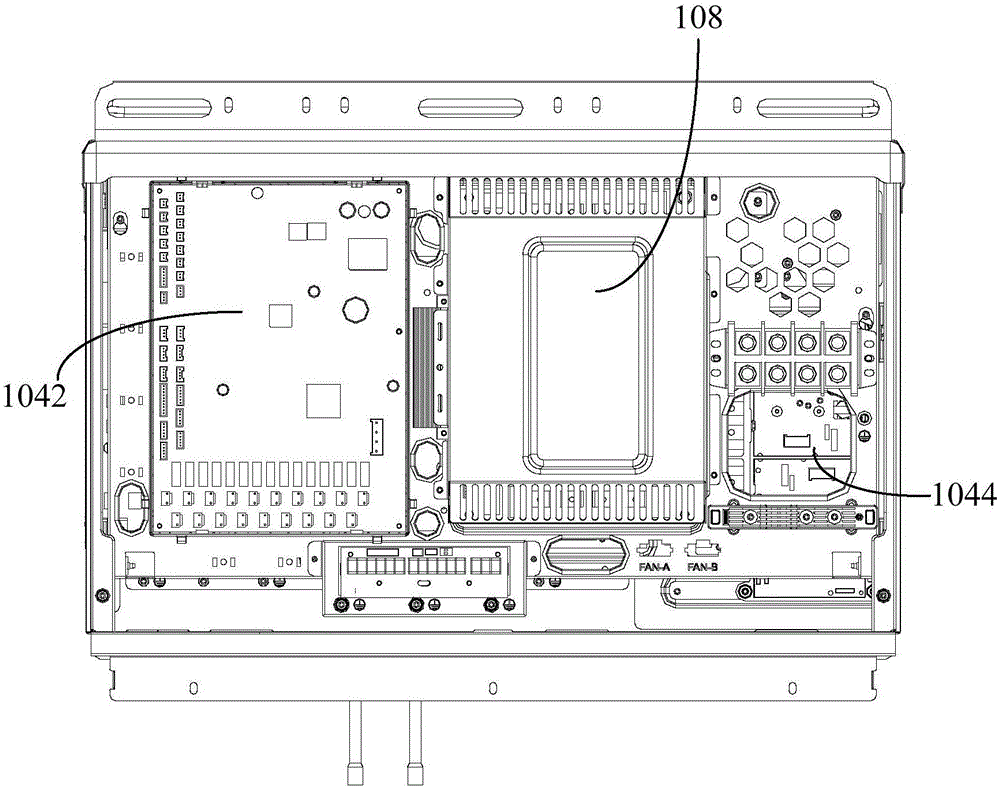

[0060] Such as Figure 1 to Figure 15 As shown, an electric control box assembly according to an embodiment of the present invention is suitable for an air conditioning system. The electric control box assembly includes: a box body 102; at least two electric control panels, which are arranged in layers in the box body 102, at least The two electric control panels include a first electric control panel 104 and a second electric control panel 106; the first electric control panel 104 and the second electric control panel 106 respectively; the main control module 1042 is located on the first electric control panel 104 The driving module is set on the second electric control panel 106, wherein the main control module 1042 is connected to the driving module through a signal line or a wireless communication unit.

[0061] In this embodiment, through at least two electric control panels arranged in layers in the box body 102, the installation space of electrical components is increas...

Embodiment 2

[0065] Such as Figure 14 As shown, the second electric control panel 106 is installed on the inner side of the backboard of the box body 102, and the electric control box assembly also includes: a first rotating member 118, which is symmetrically arranged on the inner side surfaces of the two side plates of the box body 102 ; The second rotating member 120 is arranged on the first electric control panel 104 and is arranged in cooperation with the first rotating member 118 for movably connecting the first electric control panel 104 and the box body 102 .

[0066] In this embodiment, the space utilization rate is further improved by installing the second electric control panel 106 on the inner side of the backboard of the box body 102. The first rotating part 118 and the second rotating part 120 arranged on the first electric control panel 104 in cooperation with the first rotating part 118 realize the flexible connection between the first electric control panel 104 and the box...

Embodiment 3

[0086] Such as figure 2 and Figure 4 As shown, two compressor driving modules 1062 and two fan driving modules 1064 are arranged on the second electric control panel 106, wherein the two compressor driving modules 1062 are arranged side by side on the left side of the electric control box assembly, and the two Two fan drive modules 1064 are arranged side by side on the right side of the electric control box. In addition, a reactor can also be arranged on the second electric control panel 106, which further improves the space utilization rate of the second electric control panel 106, making the second electric control panel 106 more efficient. The electrical components on the panel 106 have compact structure, scientific routing, good heat dissipation performance, and less mutual interference.

[0087] Such as Figure 1 to Figure 15 As shown, in any one of the above embodiments, preferably, the second radiator 112 is a refrigerant type radiator, and the third radiator 114 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com