Visual automatic detection system and detection method thereof

An automatic detection and automatic control system technology, applied in the direction of optical testing flaws/defects, analyzing materials, instruments, etc., can solve problems such as low detection efficiency, inconsistent standards, and inadequate assembly, so as to achieve high detection efficiency and ensure factory quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

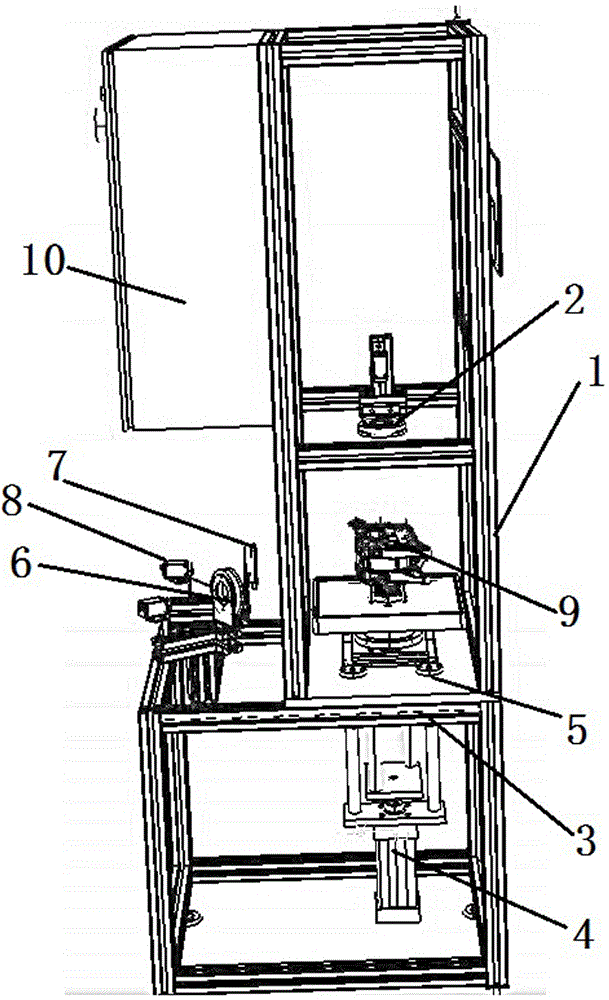

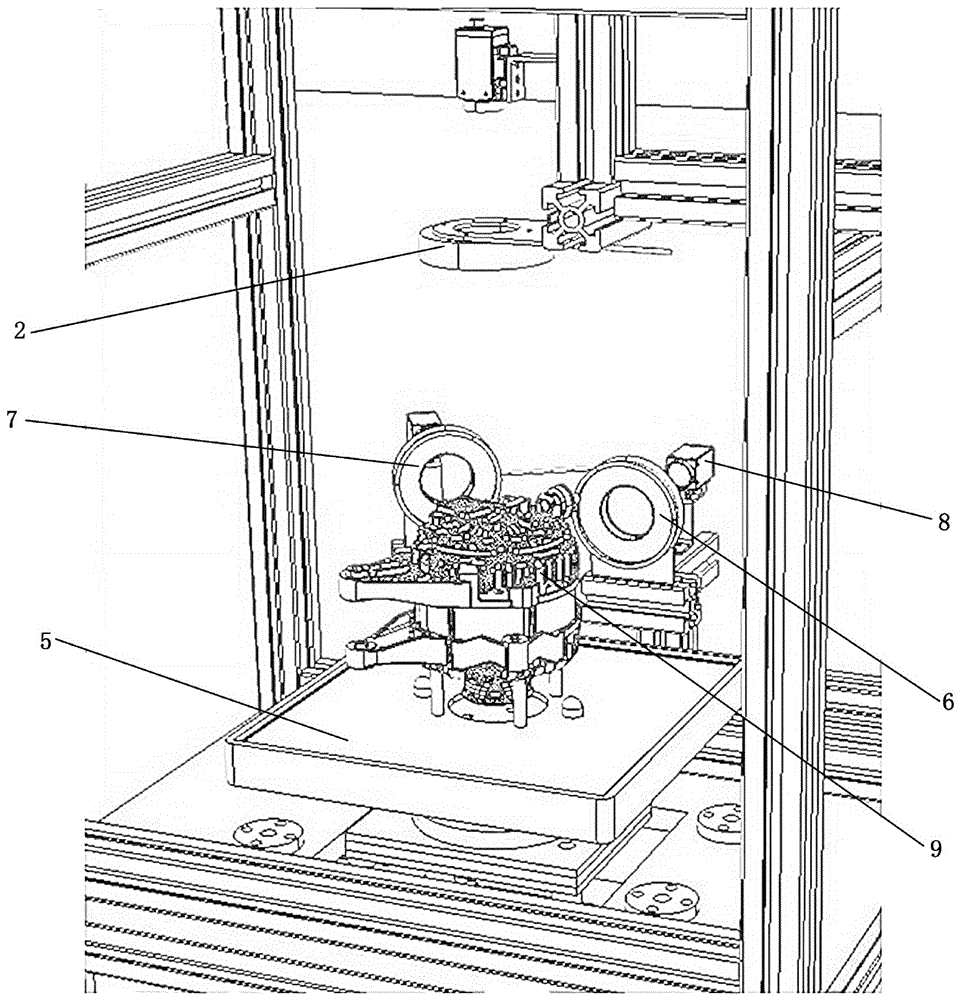

[0032] See figure 1 , figure 2 , a visual automatic inspection system, comprising a visual automatic inspection device body 1, said device body 1 including a first camera 2 arranged on the top of the device body for taking photos of bridge solder joints for detection and arrangement, an electrical cabinet 10 is arranged above the first camera, The controller and the PLC automatic control system are installed in the electrical cabinet 10. The bottom of the device body 1 is provided with a jacking and rotating device 3 that lifts and rotates the workpiece to be detected. The jacking and rotating device 3 includes a lower jacking cylinder 4 and a The upper rotating platform 5 is equipped with a second camera 6 for detecting whether the bolts are tightened in place and a third camera 7 for detecting whether the generator belts are mixed. The first camera 2, the second Camera 6 and the 3rd camera 7 rear parts are all provided with the light source 8 that is used to promote the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com