Electron beam welding method for dissimilar aluminum alloy material

A dissimilar aluminum alloy and electron beam welding technology, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of inability to realize welding of large-thickness alloy materials, single welding structure, and unfavorable wide application, etc. problem, to achieve the effect of energy concentration, smooth and beautiful weld surface, and prevention of oxidation and element burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

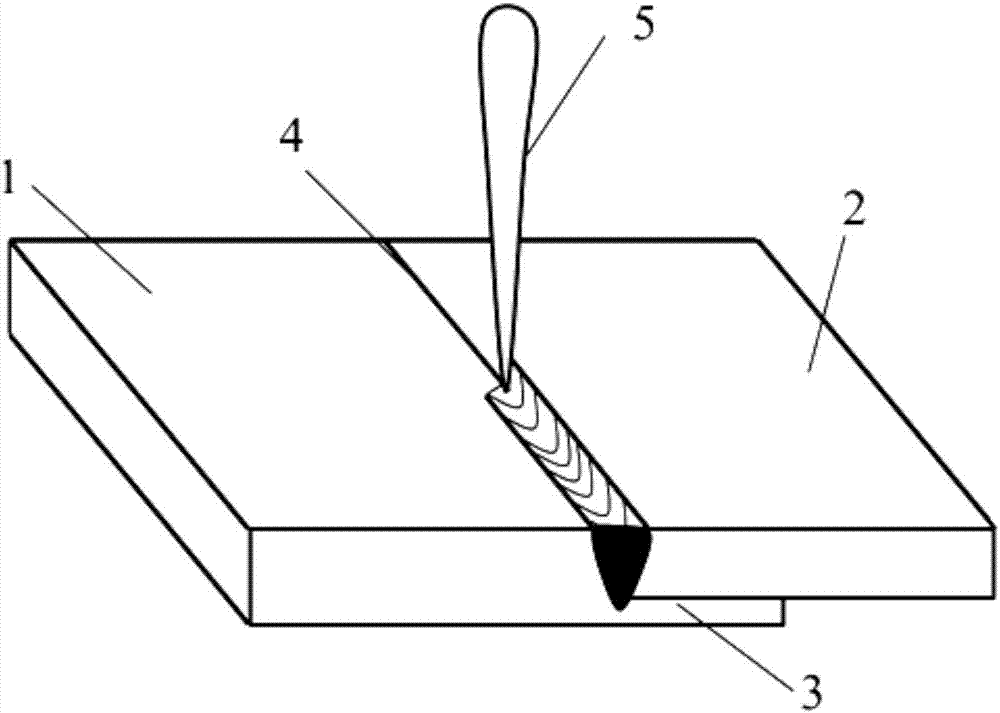

[0052] 5mm thick 5A06 / 6005A dissimilar aluminum alloy plate butt welding. as attached figure 1 As shown, the structure of the joint is butt joint with the bottom of the lock. The model 5A06 aluminum alloy plate has a 2mm lock bottom on one side, and the model 6005A aluminum alloy plate is located on the upper side of the lock bottom.

[0053] Workpiece tack welding, each segment length 25mm, tack welding parameters: working distance 200mm, acceleration voltage 50kV, focusing current surface focus +0.03A, electron beam current 20mA, welding speed 1000mm / s.

[0054] Formal welding, welding parameters: working distance 200mm, accelerating voltage 50kV, focusing current surface focus -0.02A, electron beam current 50mA, welding speed 900mm / s.

[0055] Weld surface modification welding, welding parameters: working distance 200mm, accelerating voltage 50kV, focusing current surface focus + 0.05A, electron beam current 35mA, welding speed 1000mm / s.

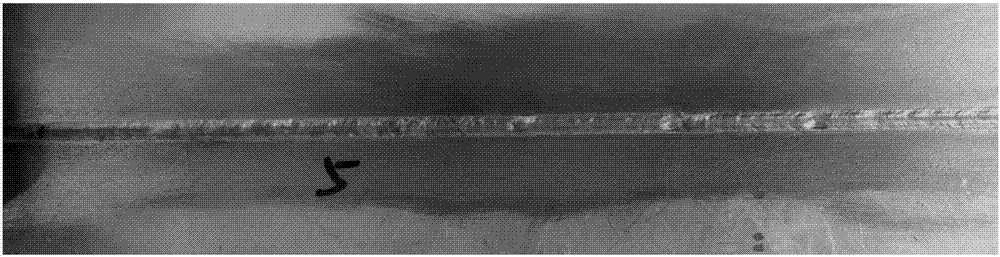

[0056] Such as figure 2 As sho...

Embodiment 2

[0058] Butt welding of 7mm thick 5A06 / 6005A dissimilar aluminum alloy plates. The structure of the joint is lock bottom butt joint, the model 5A06 alloy plate has a 3mm lock bottom on one side, and the model 6005A aluminum alloy plate is located on the upper side of the lock bottom.

[0059] Workpiece tack welding, each section length 30mm, tack welding parameters: working distance 200mm, acceleration voltage 50kV, focusing current surface focus +0.03A, electron beam current 25mA, welding speed 1000mm / s.

[0060] Formal welding, welding parameters: working distance 200mm, accelerating voltage 50kV, focusing current surface focus -0.03A, electron beam current 70mA, welding speed 1000mm / s.

[0061] Weld surface modification welding, welding parameters: working distance 200mm, accelerating voltage 50kV, focusing current surface focus + 0.1A, electron beam current 35mA, welding speed 1000mm / s.

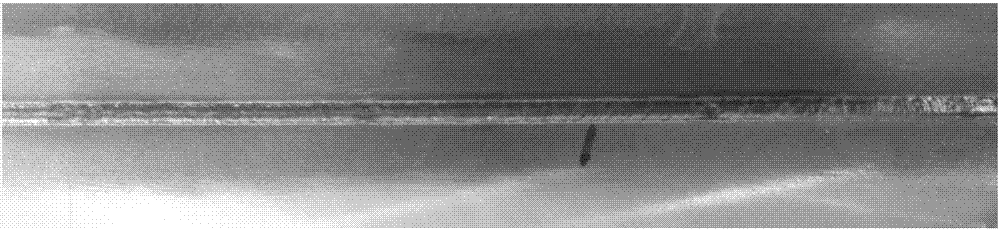

[0062] as attached image 3 As shown, the surface of the flat plate butt weld obtain...

Embodiment 3

[0064] 5mm thick 5A06 / 6005A dissimilar aluminum alloy plate butt welding. The structure of the joint is lock bottom butt joint. The model 5A06 aluminum alloy plate has a 2mm lock bottom on one side, and the model 6005A aluminum alloy plate is located on the upper side of the lock bottom.

[0065] Workpiece tack welding, each section length 20mm, tack welding parameters: working distance 200mm, acceleration voltage 50kV, focusing current surface focus +0.01A, electron beam current 30mA, welding speed 1000mm / s.

[0066] Formal welding, welding parameters: working distance 200mm, accelerating voltage 50kV, focusing current surface focus -0.01A, electron beam current 50mA, welding speed 900mm / s.

[0067] Weld surface modification welding, welding parameters: working distance 200mm, accelerating voltage 50kV, focusing current surface focus + 0.05A, electron beam current 30mA, welding speed 1000mm / s.

[0068] The surface of the flat plate butt weld obtained in this embodiment is sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap