Two-degree-of-freedom flapping wing mechanism

A technology with degrees of freedom and dynamic mechanism, applied in the field of bionic flapping-wing aircraft, can solve the problems of intermittent vibration of inner groove cam commutation, avoid additional dynamic load and impact, reduce impulse damage, and improve the effect of air lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

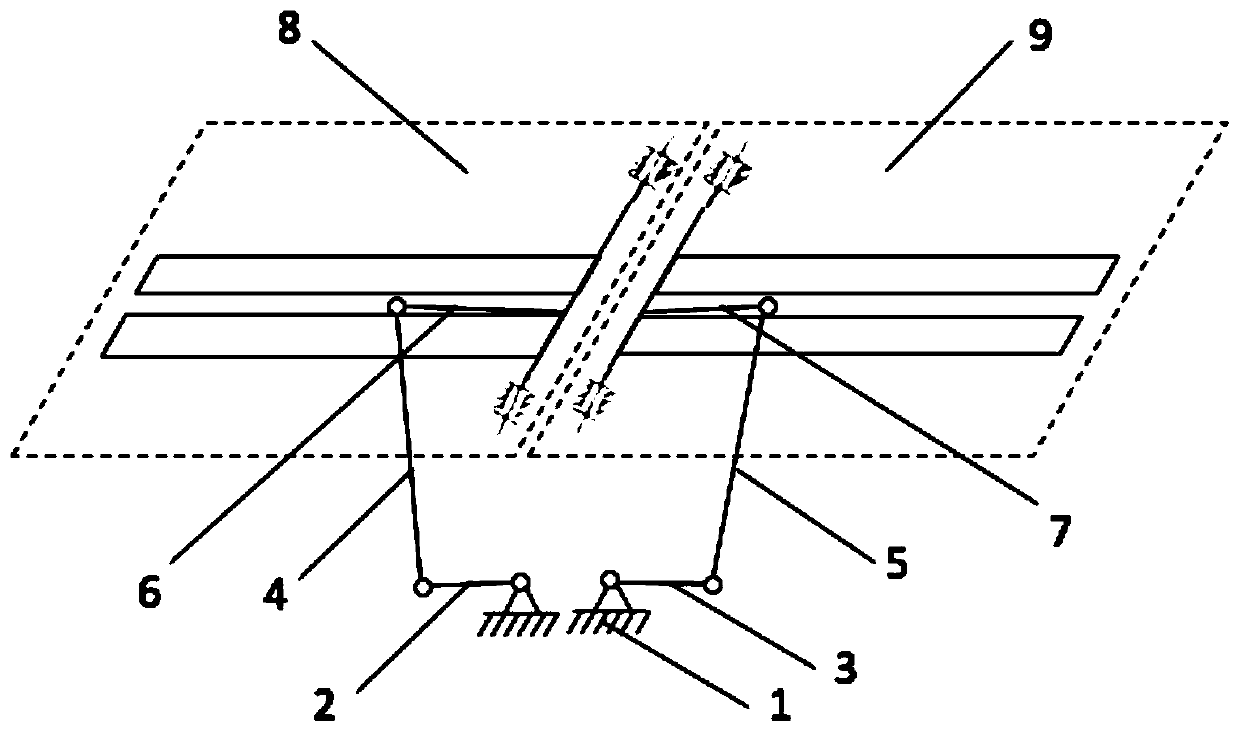

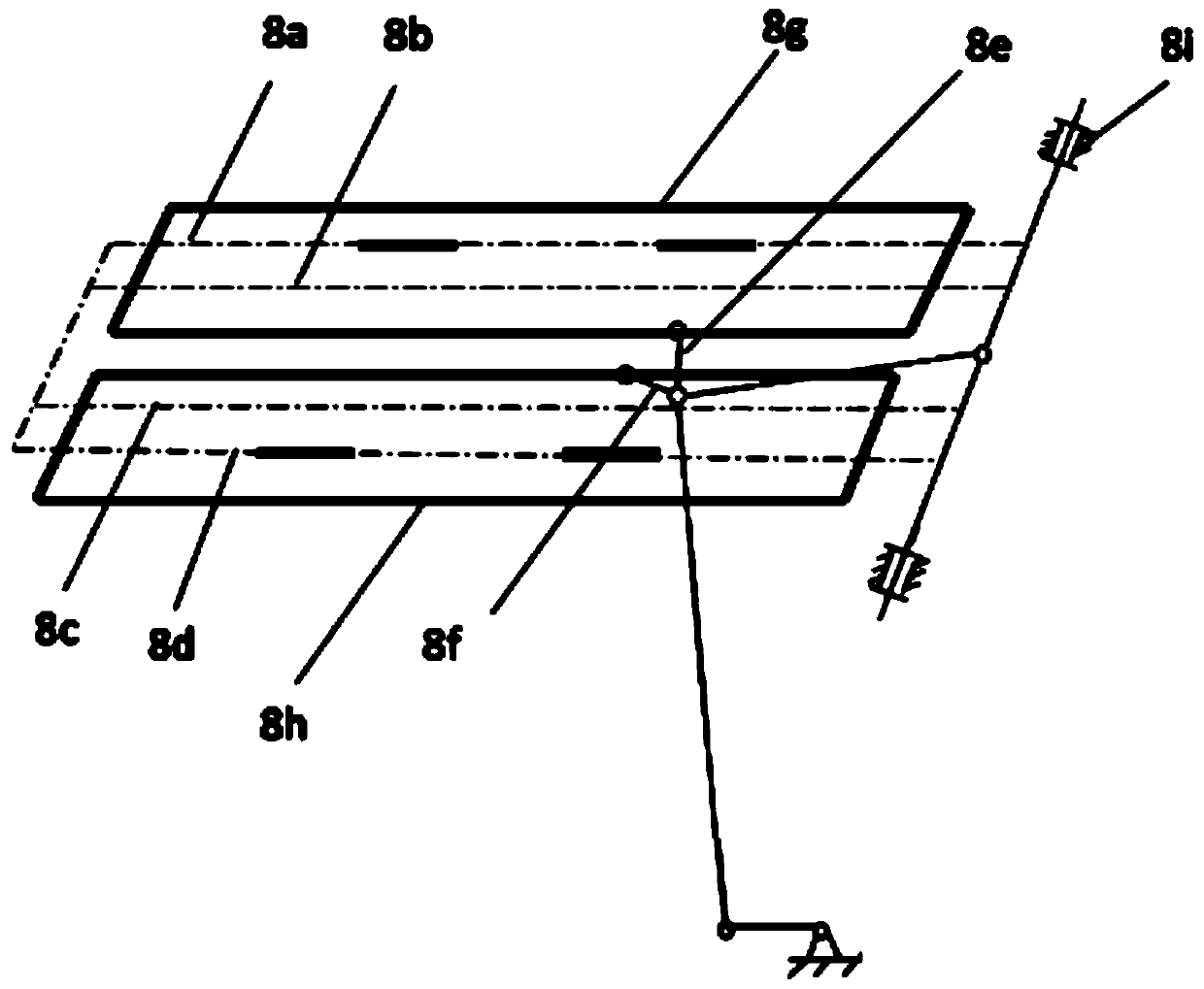

[0020] Such as figure 1 and figure 2 As shown, a two-degree-of-freedom flapping wing mechanism includes: a flapping mechanism and a wing surface rotation mechanism; the described flapping mechanism includes a crank, a connecting rod and a rocker, and the described wing surface rotation mechanism includes structurally symmetrical Left wing surface rotating mechanism 8 and right wing surface rotating mechanism 9.

[0021] The crank includes a first crank 2 and a second crank 3, the connecting rod includes a first connecting rod 4 and a second connecting rod 5, and the rocker includes a first rocker 6 and a second rocker 7 The frame 1 is connected together with the left wing surface rotation mechanism 8 through the first crank 2, the first connecting rod 4 and the first rocker 6 in turn, and the first crank 2, the first connecting rod 4 and the first The rocking rods 6 are connected by rotating pairs, so that the first crank 2, the first connecting rod 4 and the first rocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com