Transportation industrial robot with high working efficiency

A technology for industrial robots and work efficiency, applied in the field of transportation robots, can solve problems such as material loading and unloading troubles, affecting use, time-consuming and labor-consuming, etc., and achieves the effects of high practical performance, easy fixing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

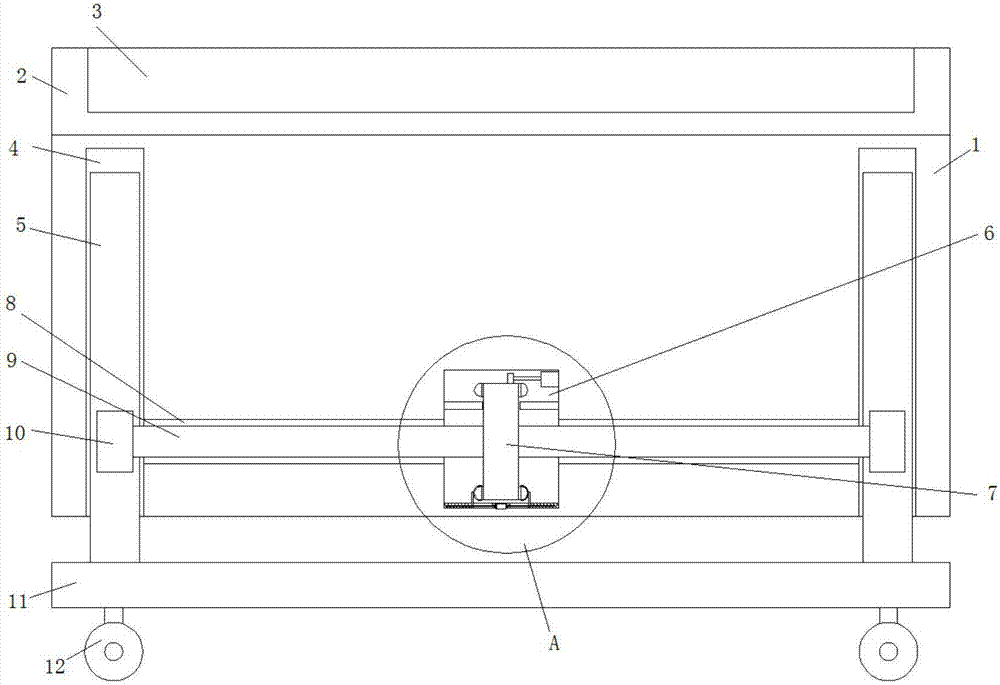

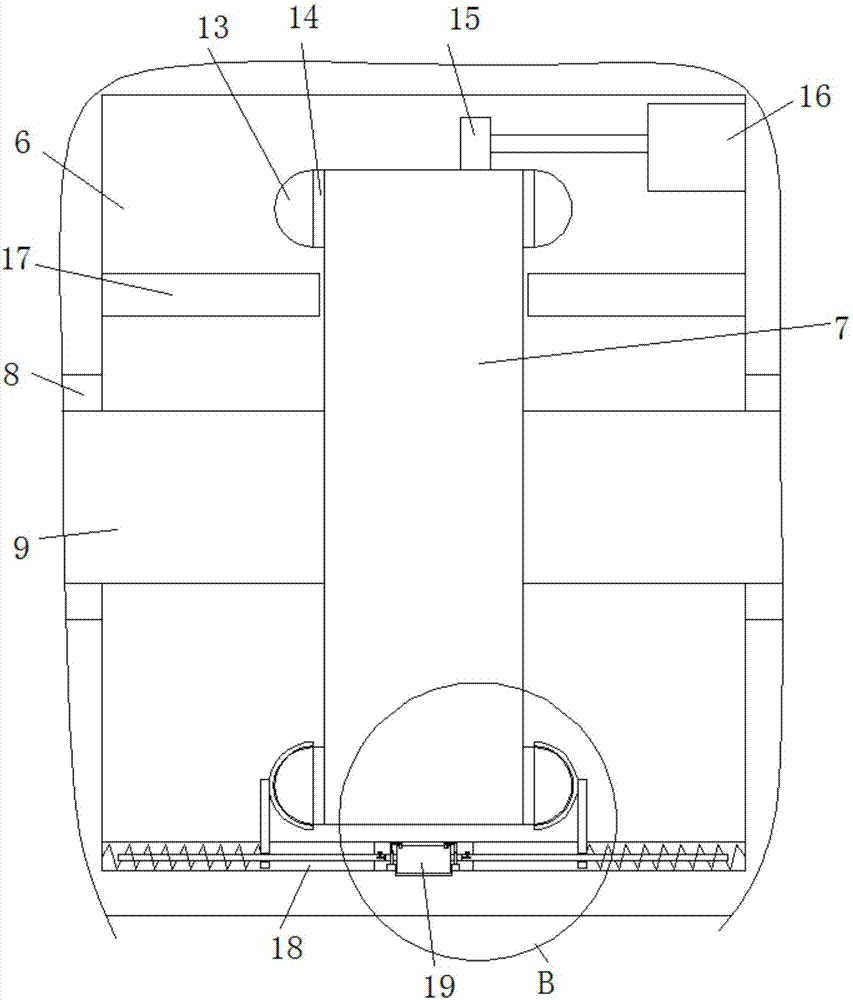

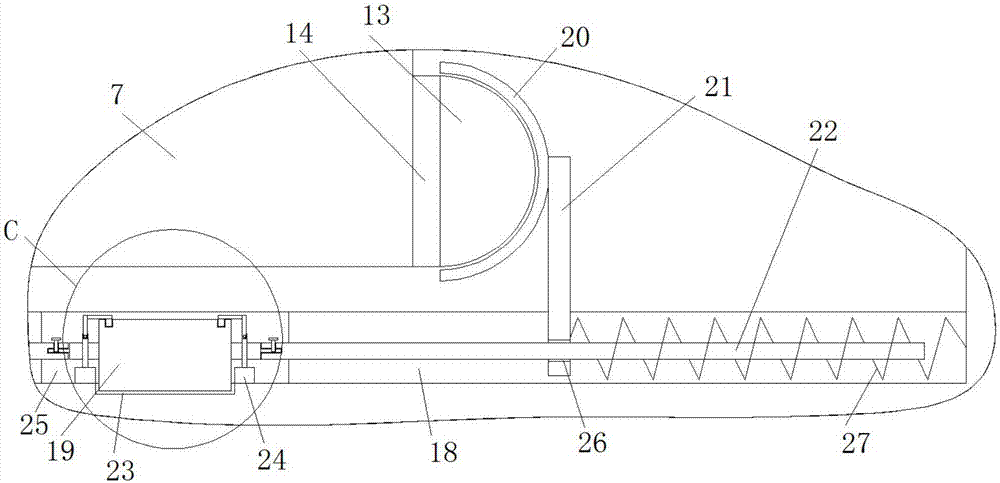

[0025] refer to Figure 1-5In this embodiment, a high-efficiency transportation industrial robot is proposed, including a robot body 1, the top of the robot body 1 is welded with a loading platform 2, and the top of the loading platform 2 is provided with a loading slot 3, and the robot body 1 The bottom of the robot is provided with two symmetrically arranged limiting grooves 4, and the limiting columns 5 are slidably installed in the limiting grooves 4. The bottom ends of the two limiting columns 5 both extend to the bottom of the robot body 1 and are welded with the same flat plate 11. , the four corners of the bottom of the flat plate 11 are all rotatably equipped with rollers 12, the robot body 1 is provided with a drive adjustment mechanism, the drive adjustment mechanism cooperates with the limit post 5, the drive adjustment mechanism includes a rotation cavity 6 provided on the robot body 1, and the rotation The cavity 6 is located between the two limiting grooves 4, a...

Embodiment 2

[0029] A high-efficiency transport industrial robot, comprising a robot body 1, the top of the robot body 1 is welded with an object stage 2, the top of the object stage 2 is provided with a loading slot 3, and the bottom of the robot body 1 is provided with two symmetrical The set limit groove 4, the limit column 5 is slidably installed in the limit groove 4, the bottom ends of the two limit columns 5 all extend to the bottom of the robot body 1 and are welded with the same flat plate 11, the bottom four corners of the flat plate 11 are A support rod is fixedly connected, and a roller 12 is installed on the support rod for rotation. The robot body 1 is provided with a drive adjustment mechanism, which cooperates with the limit post 5. The drive adjustment mechanism includes a rotation chamber 6 opened on the robot body 1. , the rotating chamber 6 is located between the two limiting grooves 4, the rotating chamber 6 is equipped with a disc 7, and the inner walls on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com