Hoisting tool and process for large connective corridor steel structure

A hoisting tool, steel structure technology, applied in transportation and packaging, load hanging components, cranes, etc., can solve the problems of danger, low efficiency, difficult hoisting of large-scale connecting beam steel structures, etc., to achieve high reliability, convenient and flexible operation , The effect of high degree of equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

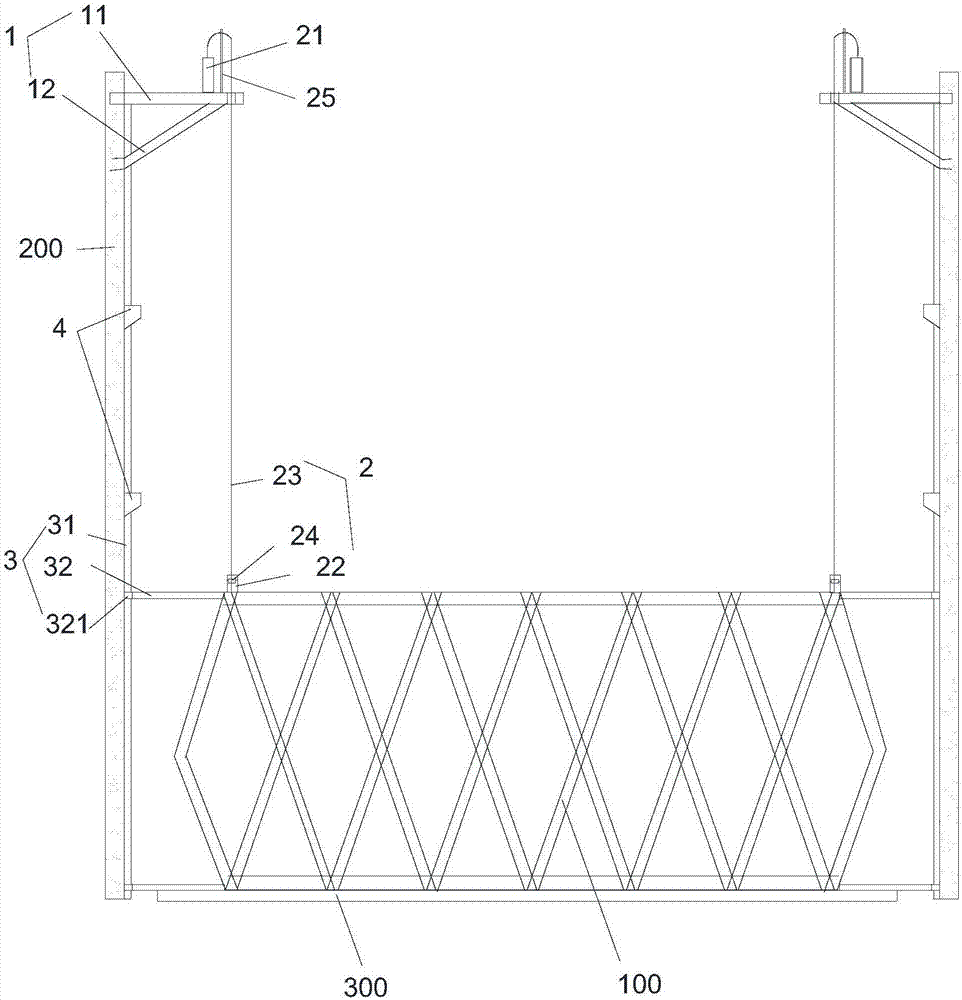

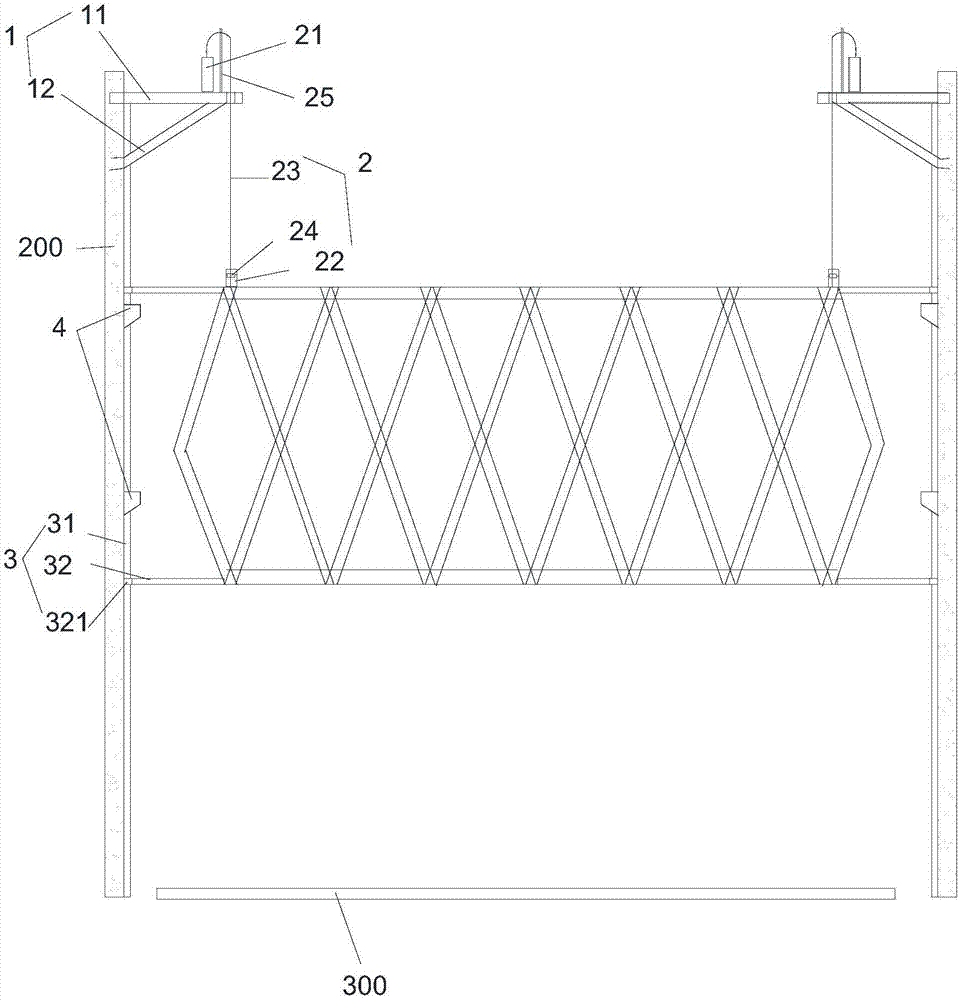

[0043] Such as figure 1 As shown, the present invention provides a hoisting tool for a large-scale corridor steel structure, including a lifting bracket 1, a lifting device 2, a lifting limit device 3 and a control system. The lifting bracket 1 is arranged above the steel structure 100 to be installed; the lifting device 2 is installed on the lifting bracket 1, and the output end of the lifting device 2 is connected to the steel structure 100; the number of lifting limit devices 3 is at least two, and all the lifting limit devices 3 are detachably connected to the steel structure 100 to be lifted ; The control system is electrically connected with the lifting device 2 and the lifting limit device 3 . The lifting limit device 3 is used to limit the steel structure 100 in the horizontal direction to prevent the steel structure 100 from shaking in the air. The large-scale corridor steel structure 100 is installed between two buildings. The number of lifting brackets 1 is an even...

Embodiment 2

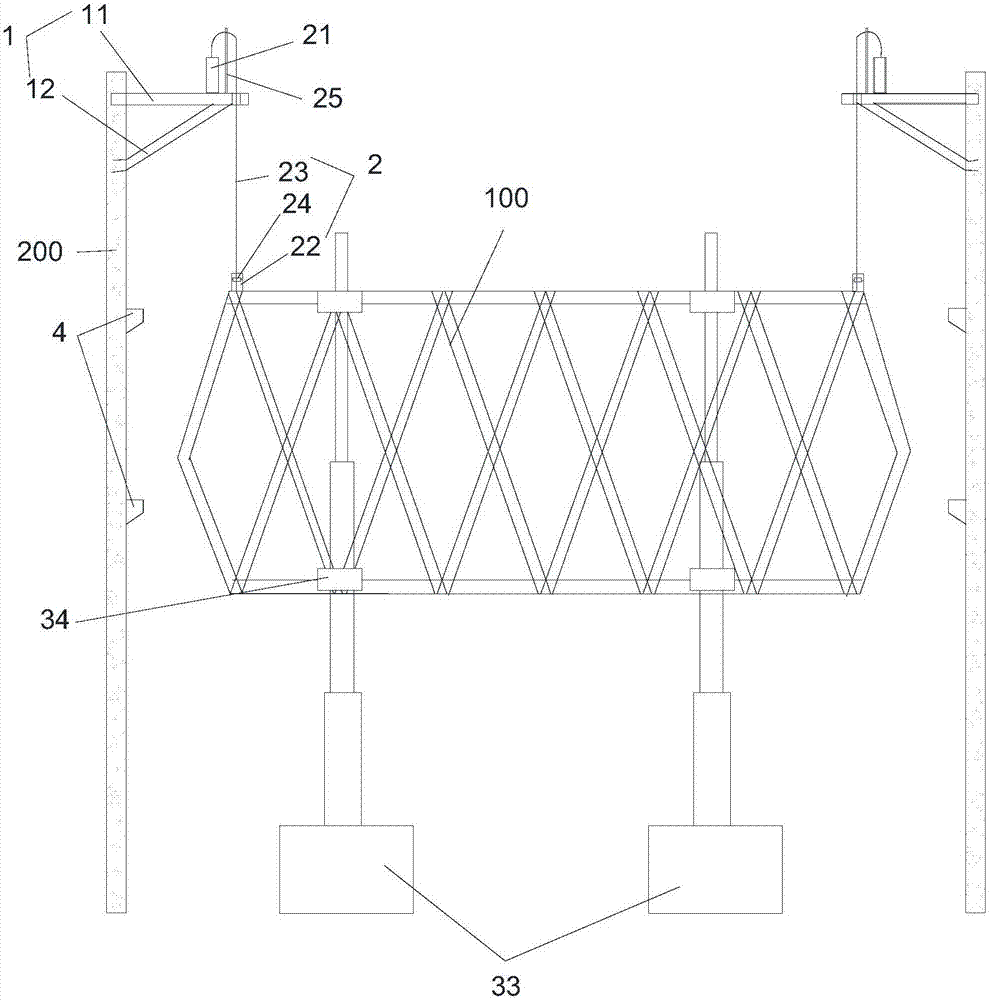

[0070] Such as image 3 As shown, compared with Embodiment 1, the present embodiment differs only in the structure of the lifting and limiting device. The lifting and limiting device 3 is installed on the front and rear sides of the steel structure 100 on the side perpendicular to the plane of the building. The lifting limit device includes an electric telescopic column set on the ground and a limit sleeve set on the steel structure. There are multiple telescopic joints of the electric telescopic column; when all the telescopic joints of the electric telescopic column are extended, The height of the electric telescopic column is the same as that of the lifting bracket from the ground, and the limit sleeve is a hollow cylindrical structure, and the limit sleeve is set on the electric telescopic column. When carrying out hoisting operations, the electric telescopic column is set on the ground, and then the sleeve is set on the telescopic joint rod of the electric telescopic colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com