A high-efficiency polyethylene catalyst active component with strong anti-toxicity and its preparation method and application

A technology of active components and polyethylene, applied in the field of high-efficiency polyethylene catalyst active components and its preparation, can solve the problems of poor control of production process parameters, complicated preparation process, complex catalyst preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

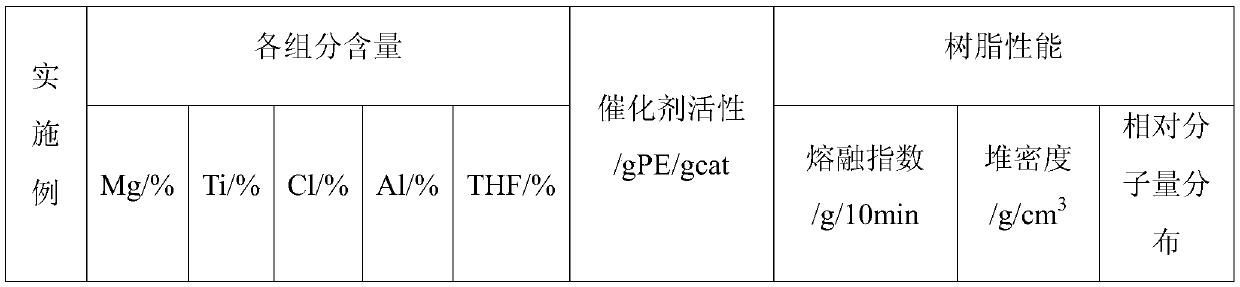

Examples

Embodiment 1

[0067] Add 1000Kg of tetrahydrofuran and 30Kg of titanium trichloride to the reaction kettle and stir for 3.5h, program the temperature to increase the temperature of the stirring kettle to 75°C, stir at high speed (200r / min), observe through the sight glass that all the titanium trichloride is dissolved. Keep the temperature in the reactor at 50-80°C, stir at low speed (100r / min) with agitator, and mix the solution for later use.

[0068] Add 183Kg of magnesium dichloride and 22kg of ethanol to the mother liquor preparation tank of the prepared mixed solution of titanium trichloride and tetrahydrofuran, stir for 0.5h, stir at high speed (200r / min), keep the temperature in the preparation tank at 80°C, and react for 9h.

[0069] After the mother liquor reaction is completed, add 200Kg of fumed silica (with a particle size of 20μm and a surface area of 230m) into the mixing and beating tank 2 / g), stir with agitator at low speed (100r / min), program the temperature to about 60℃, use...

Embodiment 2

[0072] Add 500Kg of tetrahydrofuran and 20Kg of titanium trichloride to the reaction kettle and stir for 2.5h, program the temperature to increase the temperature of the stirring kettle to 75°C, stir at high speed (180r / min), observe through the sight glass that all the titanium trichloride is dissolved. Keep the temperature in the reactor at 50-80°C, stir at low speed (90r / min) with agitator, and mix the solution for later use.

[0073] Add 85Kg of magnesium dichloride and 11kg of ethanol to the prepared mother liquor preparation tank of the mixed solution of titanium trichloride and tetrahydrofuran, stir for 1h, stir at high speed (180r / min), keep the temperature in the preparation tank at 80°C, and react with timing for 7h.

[0074] After the mother liquor reaction is completed, 110Kg of fumed silica is added to the mixing and beating tank, the mixer is stirred at low speed (90r / min), the temperature is programmed to about 60℃, and the temperature of the dry silica gel is heated ...

Embodiment 3

[0077] Add 800Kg of tetrahydrofuran and 15Kg of titanium trichloride to the reaction kettle and stir for 3h, program the temperature to increase the temperature of the stirring kettle to 75°C, stir at high speed (160r / min), observe through the sight glass that all the titanium trichloride is dissolved. Keep the temperature in the reactor at 50-80°C, stir at low speed (80r / min) with agitator, and mix the solution for later use.

[0078] Add 150Kg of magnesium dichloride and 29Kg of 1,4-butanediol to the mother liquor preparation tank of the prepared mixed solution of titanium trichloride and tetrahydrofuran, stir for 2h, stir at high speed (160r / min), keep the temperature in the preparation tank at 80℃, and time to react 8h.

[0079] After the mother liquor reaction is completed, add 150Kg of fumed silica into the mixing and beating tank, stir at low speed (80r / min) with agitator, program the temperature to about 60℃, and use 80℃ temperature-regulating water to heat the dry silica g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com