Polyurethane composite material

A composite material, polyurethane technology, applied in the field of polyurethane composite materials, can solve problems such as difficult to handle, toxicity, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0073] First prepare the mold, and then apply the mixture of the polyurethane reaction system and the rubber granules at a material temperature of 25° C. to the mold. The used isocyanate prepolymer is prepolymer A; the rubber particles are black EPDM rubber particles: the particle size is 1-3mm.

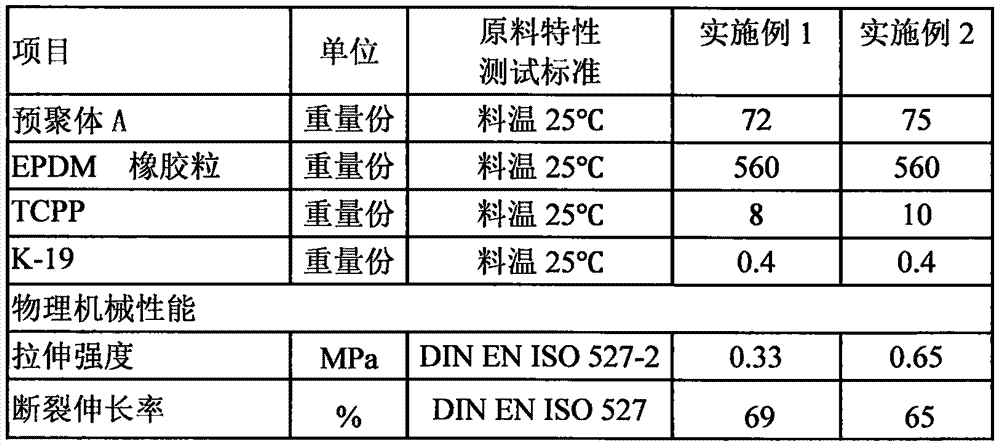

[0074] The above prepolymer A is reacted with the polyurethane reaction system mixed with rubber particles in the mold (about 60°C) to form a composite pad of polyurethane matrix material and rubber particles filled in the polyurethane matrix material, and the cured molded The rubber particle polyurethane composite mat is taken out from the mold to obtain the rubber particle polyurethane composite ballast mat of the present invention. The test mechanical properties are shown in Table 2.

[0075] Table 2: Formula and performance of rubber particle polyurethane composite ballast mat

[0076]

Embodiment 3

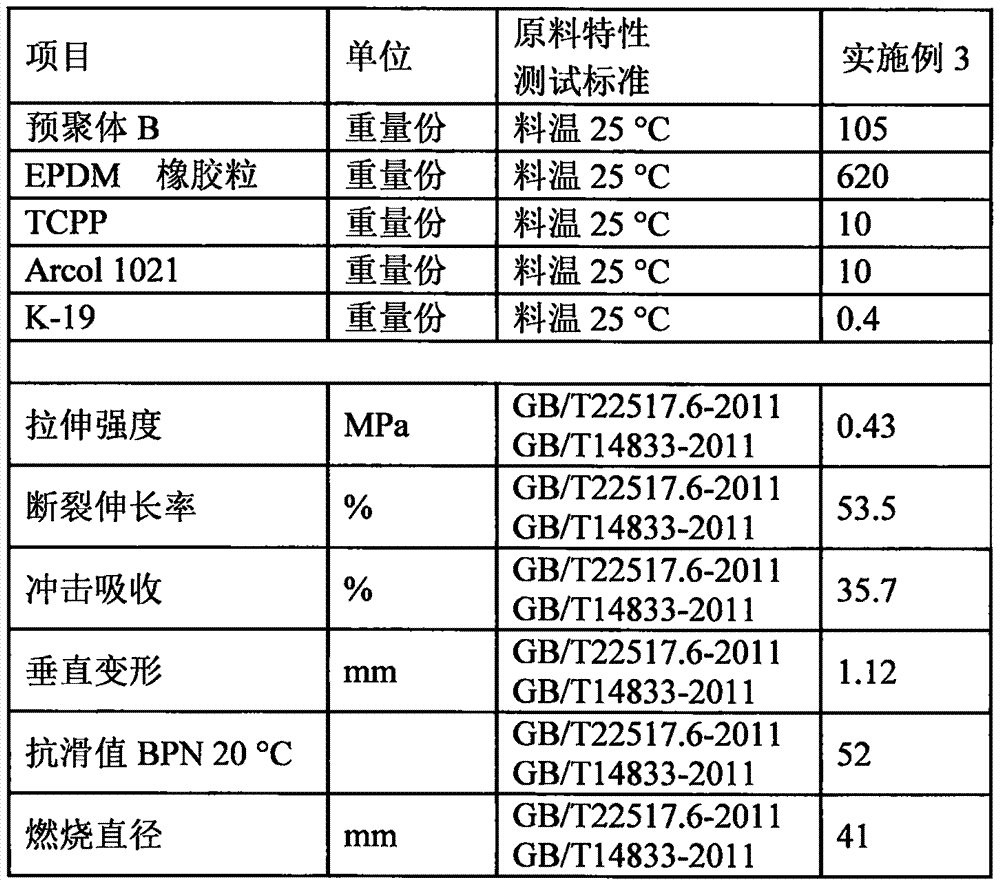

[0078] First prepare the mold, and then apply the mixture of the polyurethane reaction system and the rubber granules at a material temperature of 25° C. to the mold. The isocyanate prepolymer used is prepolymer B; the rubber particles are black EPDM rubber particles: particle size 1-3mm.

[0079] React the polyurethane reaction system mixed with rubber particles in the mold to form a composite pad of polyurethane matrix material and rubber particles filled in the polyurethane matrix material, and take out the rubber particle polyurethane composite pad after curing and molding from the mold to obtain rubber particles Polyurethane composite pad. The properties of the prepared rubber particle polyurethane composite pad are shown in Table 3.

[0080] Table 3: Formula and performance of rubber particle polyurethane composite ballast mat

[0081]

[0082] It can be seen from the performance data of Examples 1-3 that the rubber particle polyurethane composite ballast mat provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com