Nano-gold self-assembled Si sheet material and application thereof

A nano-gold, self-assembly technology, applied in the direction of nanotechnology, analytical materials, material excitation analysis, etc., to achieve good uniformity and stability, simple and fast method, and good synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

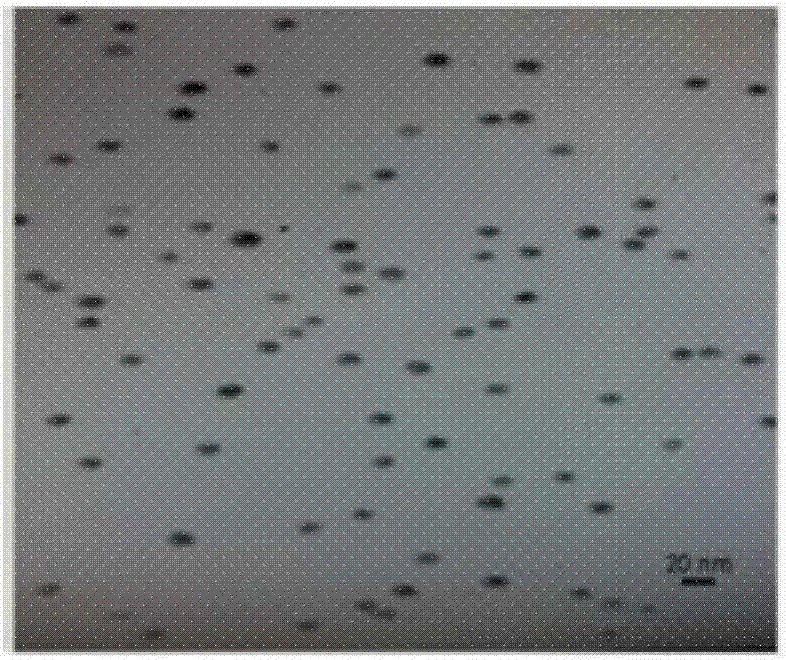

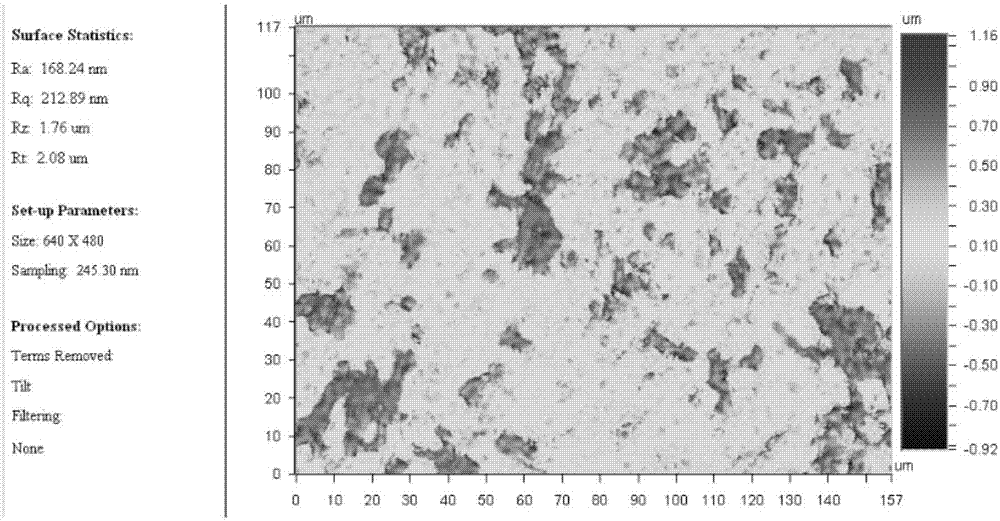

[0027] Embodiment 1 nano-gold self-assembled Si sheet material

[0028] (1) SiO 2 @Si chip cleaning

[0029] SiO 2 @Si slice (i.e. SiO 2 Coated Si wafers (purchased from Zhejiang Lijing Silicon Materials Co., Ltd.) were immersed in acetone, ethanol and deionized water in turn, cleaned by ultrasonic waves at 100W for 15min, and then dried with nitrogen to obtain SiO after cleaning. 2 @Si slice.

[0030] (2) activation

[0031] SiO after step (1) cleaning 2 @Si sheet undergoes activation treatment to form SiO with amino terminal on the surface 2 @Si slice:

[0032] SiO after step (1) cleaning 2 The @Si piece is immersed in 1mol / L NaOH aqueous solution, stirred ultrasonically at 100W for 10min, so that the surface is covered with a layer of hydroxyl group (-OH), take it out and rinse it with deionized water, dry it at room temperature, and then put it in a concentration of 1% Soak in a methanol solution of 3-aminopropyl-trimethoxysilane (APTMS) for 24 hours at room tempe...

Embodiment 2

[0038] (1) SiO 2 @Si chip cleaning

[0039] With embodiment 1.

[0040] (2) activation

[0041] SiO after step (1) cleaning 2 @Si sheet undergoes activation treatment to form SiO with amino terminal on the surface 2 @Si slice:

[0042] SiO after step (1) cleaning 2 The @Si piece is immersed in 2mol / L NaOH aqueous solution, stirred ultrasonically for 20min at 100W, so that the surface is covered with a layer of hydroxyl group (-OH), taken out, rinsed with deionized water, dried at room temperature, and then put into a solution with a mass concentration of 2%. Soak in methanol solution of 3-aminopropyl-trimethoxysilane (APTMS) at room temperature for 12 hours to silanize the surface of the substrate and expose the amino group at the end, take it out and rinse it with deionized water, dry it at room temperature, and then put it in 0.2mol / L Stand in the aqueous HCl solution for 40 minutes to protonate the terminal amino group by electrostatic adsorption, take it out, wash it...

Embodiment 3

[0048] (1) SiO 2 @Si chip cleaning

[0049] With embodiment 1.

[0050] (2) activation

[0051] SiO after step (1) cleaning 2 @Si sheet undergoes activation treatment to form SiO with amino terminal on the surface 2 @Si slice:

[0052] SiO after step (1) cleaning 2 The @Si piece is immersed in a 1mol / L NaOH aqueous solution, stirred ultrasonically at 100W for 10min, so that the surface is covered with a layer of hydroxyl (-OH), taken out, rinsed with deionized water, dried at room temperature, and then put into a solution with a mass concentration of 3%. Soak in methanol solution of 3-aminopropyl-trimethoxysilane (APTMS) for 18 hours at room temperature to silanize the surface of the substrate and expose the amino group at the end, take it out and rinse it with deionized water, dry it at room temperature, and then put in 0.3mol / L Stand in HCl aqueous solution for 60min to protonate the terminal amino group by electrostatic adsorption, take it out, wash it with deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com