Cast-in-situ thermal-insulation integrated slope roof structure and construction method

A sloping roof and integrated technology, which is applied in the field of cast-in-place thermal insulation integrated sloping roof structure and construction, can solve the problems of difficult roof detail processing, complex construction technology, complex decoration structure, etc. The effect of firm connection and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

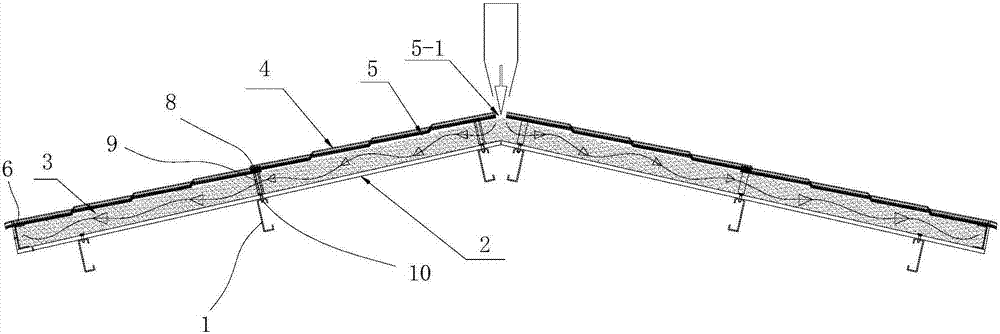

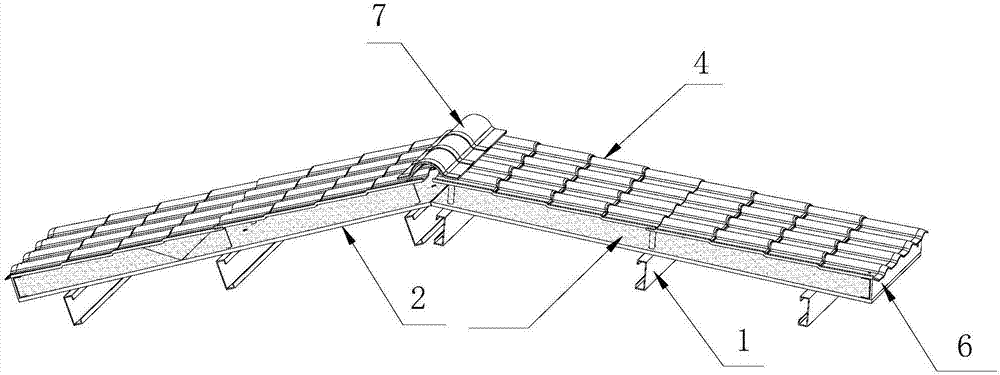

[0035] Example 1, see figure 1 and 2 , a cast-in-place thermal insulation integrated sloping roof structure, comprising purlins 1, an interior decoration carrier 2, an insulation layer 3 and roof tiles 4; the interior decoration carrier is fixedly connected to the purlin 1, above the interior decoration carrier Roof tiles 4 are installed through support members, the decorative carrier and roof tiles are at least equal to the span between two adjacent purlins in the length direction, and an insulation layer accommodation cavity 5 is formed between the interior decoration carrier and roof tiles, A plugging plate 6 is fixedly installed between the bottom of the insulation layer accommodation cavity and between the side roof tiles and the interior decoration carrier. The upper part of the insulation layer accommodation cavity is an open structure, forming a cast-in-place insulation layer pouring port 5-1, and the pouring is completed. Finally, the roof ridge cover plate 7 is fixe...

Embodiment 2

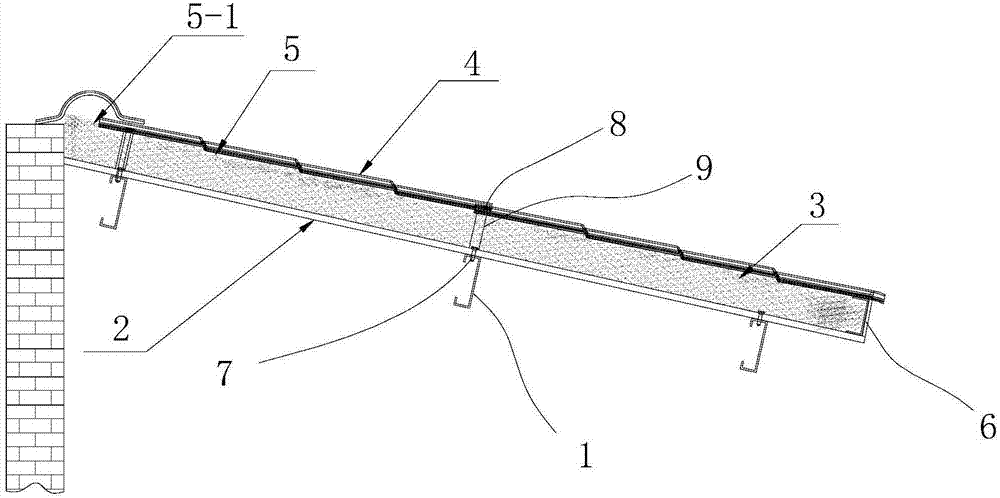

[0039] Embodiment 2, this embodiment is also suitable for mono-pitch roofs, such as image 3 .

Embodiment 3

[0040] Example 3, see Figure 4 , preferably in this embodiment, the interior decoration carrier 2 is installed on the lower surface of the purlin 1 through the third fastening screw 11; the upper surface of the purlin is laid with roof tiles 4, and the roof tile is passed through the fourth The fastening screw 12 is fixedly connected with the purlin 1 . All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com