Ultra-low temperature and ultra-high pressure liquid hydrogen pump

An ultra-high pressure, ultra-low temperature technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve problems such as poor adaptability and poor sealing effect, and achieve good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

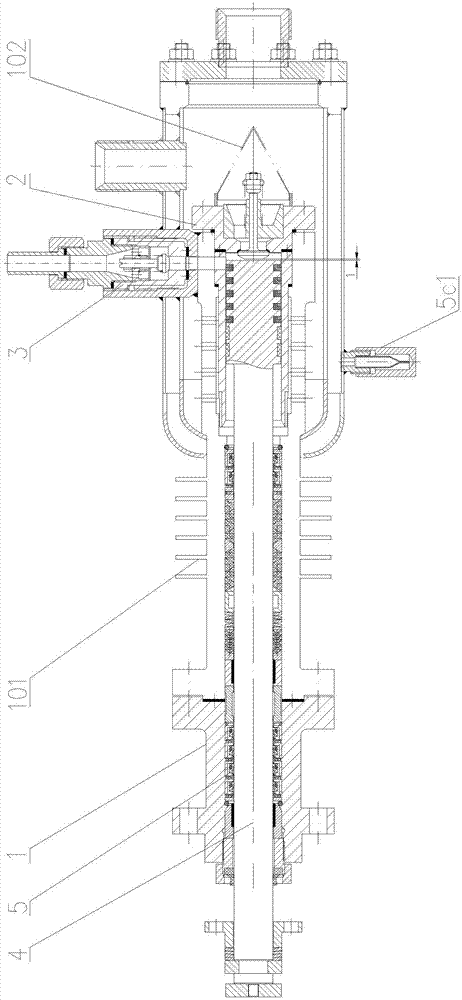

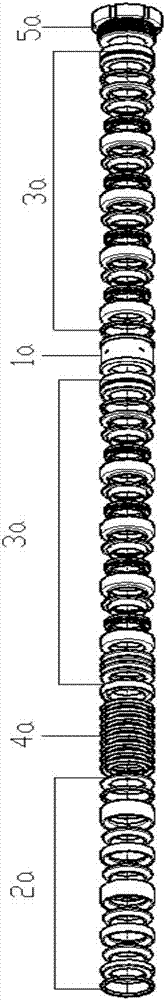

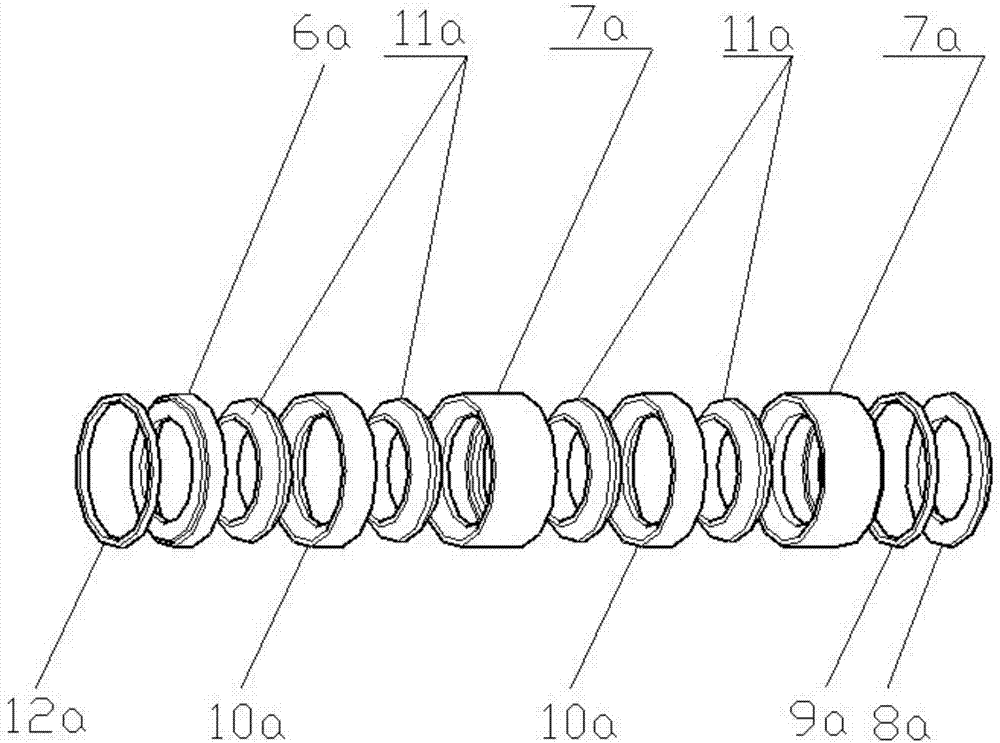

[0027] Ultra-low temperature and ultra-high pressure liquid hydrogen pumps, such as Figure 1-Figure 10 As shown, the pump body 1 is included. The pump body 1 is provided with a liquid inlet valve 2 and a liquid outlet valve 3. The pump body 1 is also provided with a piston rod 4 for controlling the liquid discharge. The piston rod 4 is provided with a sealing structure 5. The sealing structure 5 includes a sealing bushing 5a1, at least one air-filling hole 5b1 is opened on the sealing bushing 5a1, an inflation tube 5c1 matched with the sealing bushing 5a1 is arranged on the pump body 1, and the left end of the sealing bushing 5a1 is sequentially arranged from left to right. There are sealing assembly 1 2a, sealing assembly 2 3a, the right end of the sealing shaft sleeve 5a1 is provided with sealing assembly 2 3a, a butterfly spring 4a is arranged between the sealing assembly 1 2a and the sealing assembly 2 3a at the left end of the sealing sleeve 5a1, and the sealing sleeve T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com