An analytical method for detecting catalase activity in textile printing and dyeing industry

A catalase, textile printing and dyeing technology, applied in the direction of material analysis by optical means, analysis of materials, preparation of test samples, etc., can solve the problems of large system error, increased test time, and high requirements for operators' technical level. , to achieve high accuracy and repeatability, reduce system errors, and save test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

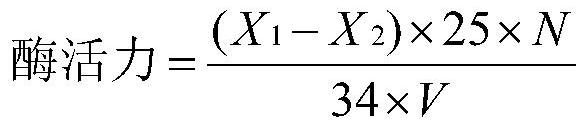

[0040] An analytical method for detecting catalase activity in the textile printing and dyeing industry, comprising the following steps:

[0041] (1) Drawing of calibration curve

[0042] Accurately draw 0.00mL, 0.25mL, 0.50mL, 0.70mL, 1.00mL, 2.5mL, 5.00mL, 7.00mL and 10.00mL of 20mg / L hydrogen peroxide standard solution into a 25mL stoppered colorimetric tube, add 5mL concentration It is 5g / L titanium dioxide-sulfuric acid solution, dilute to 25mL, shake well, after standing for 10min, measure the absorbance at 430nm with a 1cm cuvette;

[0043] According to the absorbance and the corresponding hydrogen peroxide content, draw a calibration curve.

[0044] (2) Determination of samples

[0045] (2-1) Add 5mL, 20mg / L hydrogen peroxide substrate solution in three 25mL colorimetric tubes, dilute the enzyme solution to be tested with pH=7.0 buffer solution to obtain the enzyme dilution solution to be tested, Put the hydrogen peroxide substrate solution and the enzyme dilution t...

Embodiment 2

[0064] The analytical method of catalase activity in the detection textile printing and dyeing industry of the present embodiment is basically the same as that of Example 1, the difference is that the H added in the step (2-2) and the step (2-3) of the present embodiment 2 SO 4 The volume is 2mL.

Embodiment 3

[0066] The analytical method of catalase activity in the detection textile printing and dyeing industry of the present embodiment is basically the same as that of Example 1, the difference is that the H added in the step (2-2) and the step (2-3) of the present embodiment 2 SO 4 The volume is 7mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com