Convenient mower and working method thereof

A working method and lawn mower technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems that weeds cannot be completely cleaned up, staff's arms are uncomfortable, and it takes a lot of labor and time to achieve The effect of solving the difficulty of recycling broken grass, solving the discomfort, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

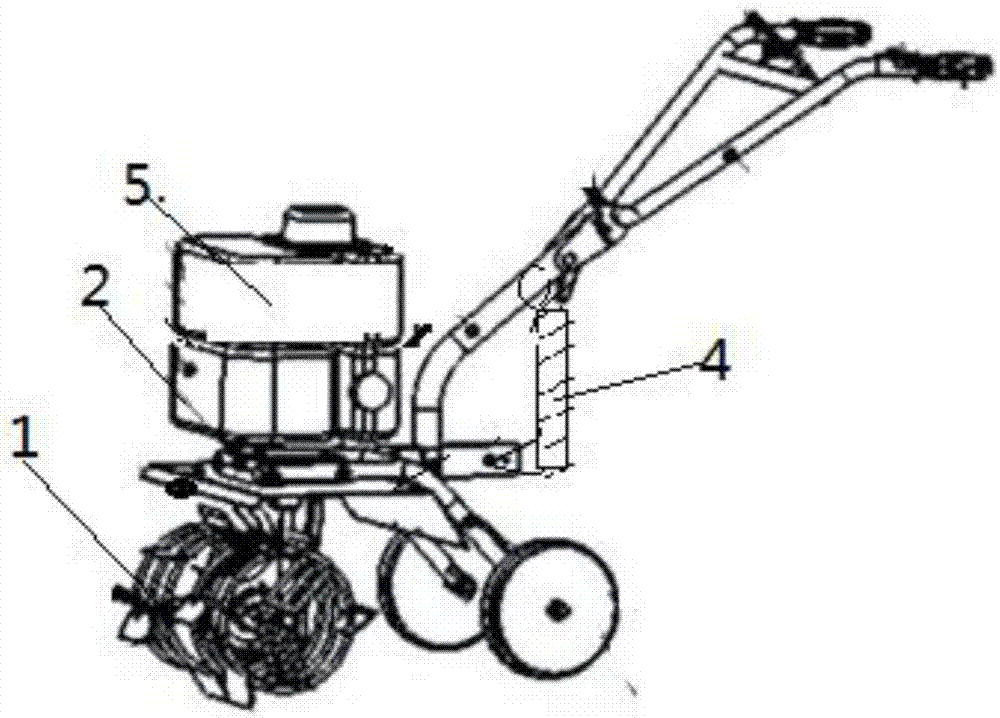

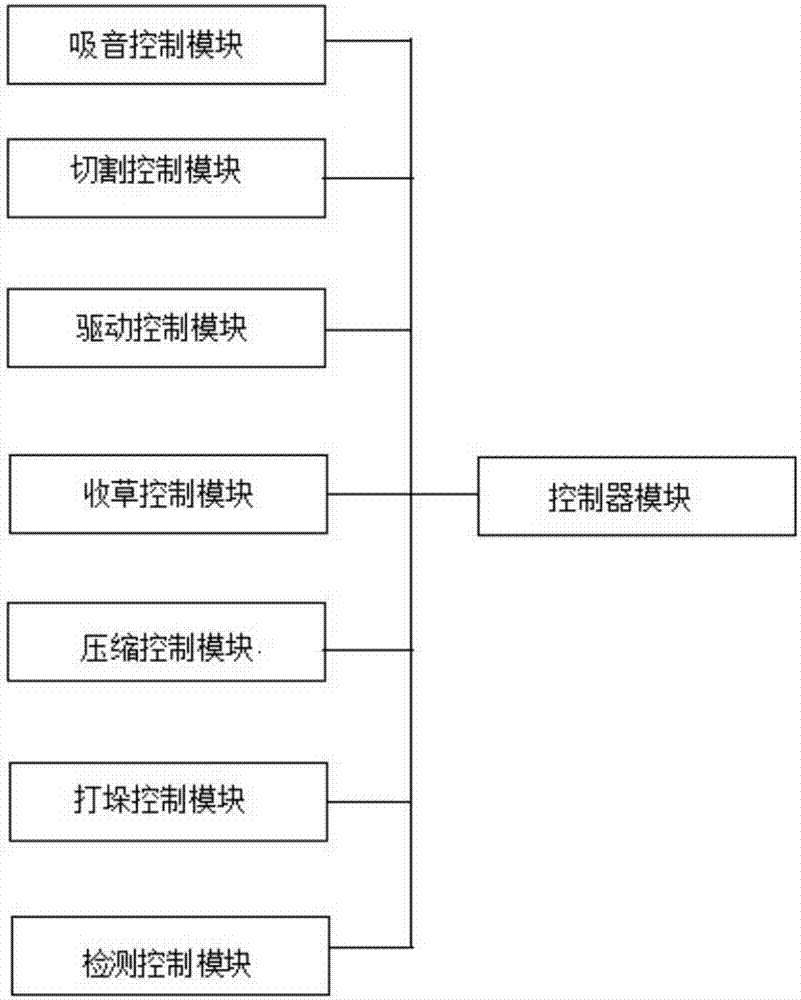

[0034] A working method of a convenient lawnmower as shown in the figure, wherein the lawnmower includes: a lawnmower body, the lawnmower body is provided with a cutting mechanism 1, a driving mechanism 2, a grass harvesting mechanism 3, a cutting mechanism Vibration mechanism 4 and control device 5, wherein, described grass collecting mechanism 3 is provided with compression device 6;

[0035] The relationship between the above components is as follows:

[0036] The input and output ends of the drive mechanism 2 are connected with the cutting mechanism 1 respectively, the grass collecting mechanism 3 is arranged at the rear of the cutting mechanism 1, and the shock absorbing mechanism 4 is arranged on the handrail of the mower, and the cutting mechanism 1. The driving mechanism 2, the grass collecting mechanism 3, the damping mechanism 4 and the compression device 6 are all connected to the control device 5.

[0037] In this embodiment, the compression mechanism 5 is provide...

Embodiment 2

[0045]A working method of a convenient lawnmower as shown in the figure, wherein the lawnmower includes: a lawnmower body, the lawnmower body is provided with a cutting mechanism 1, a driving mechanism 2, a grass harvesting mechanism 3, a cutting mechanism Vibration mechanism 4 and control device 5, wherein, described grass collecting mechanism 3 is provided with compression device 6;

[0046] The relationship between the above components is as follows:

[0047] The input and output ends of the drive mechanism 2 are respectively connected with the cutting mechanism 1, the grass collecting mechanism 3 is arranged at the rear of the cutting mechanism 1, and the damping mechanism 4 is arranged on the handrail of the mower, and the cutting mechanism 1. The driving mechanism 2, the grass collecting mechanism 3, the damping mechanism 4 and the compression device 6 are all connected to the control device 5.

[0048] In this embodiment, the compression mechanism 5 is provided with a ...

Embodiment 3

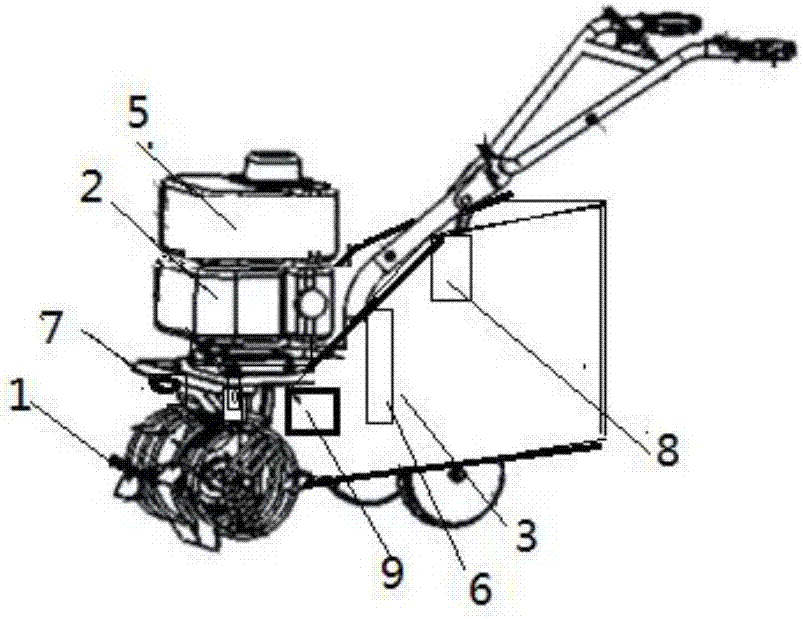

[0057] A working method of a convenient lawnmower as shown in the figure, wherein the lawnmower includes: a lawnmower body, the lawnmower body is provided with a cutting mechanism 1, a driving mechanism 2, a grass harvesting mechanism 3, a cutting mechanism Vibration mechanism 4, noise reduction device 9 and control device 5, wherein, described grass collecting mechanism 3 is provided with compression device 6;

[0058] The relationship between the above components is as follows:

[0059] The input and output ends of the drive mechanism 2 are respectively connected with the cutting mechanism 1, the grass collecting mechanism 3 is arranged at the rear of the cutting mechanism 1, and the damping mechanism 4 is arranged on the handrail of the mower, and the cutting mechanism 1. The driving mechanism 2, the grass collecting mechanism 3, the damping mechanism 4 and the compression device 6 are all connected to the control device 5.

[0060] In this embodiment, the compression mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com