3D printer capable of preventing powder from blocking spray head

A 3D printer and printer technology, applied in the field of 3D printing, can solve problems affecting customer experience, affecting the use of 3D printers, shortening the life of printer nozzles, etc., to achieve the effect of avoiding powder residue, avoiding damage, and ensuring flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

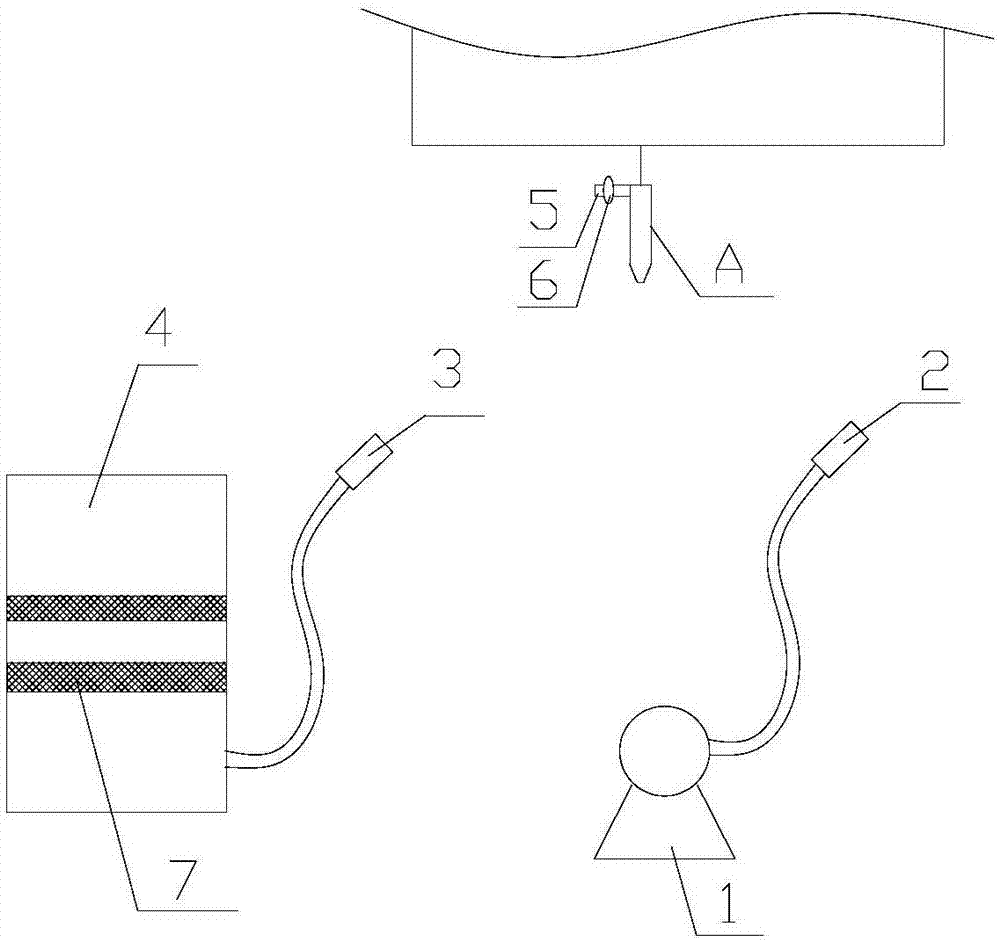

[0018] refer to figure 1 , the present invention proposes a 3D printer for preventing powder clogging nozzles, comprising: an air pump 1 , a first butt joint 2 , a second butt joint 3 and a recovery box 4 .

[0019] The end of the nozzle A of the printer away from the nozzle is provided with a backflush conduit 5, and the backflush conduit 5 is provided with a cut-off valve 6 to prevent the printer nozzle A from leaking through the backflush conduit 5 during normal operation.

[0020] One end of the first pair of joints 2 is connected to the output end of the air pump 1, and the other end is adapted to the outlet of the nozzle A of the printer. One end of the second pair of connectors 3 is connected to the input port of the recovery box 4 , and the other end is adapted to the backwash conduit 5 .

[0021] In this embodiment, the end where the nozzle A of the printer is located is provided with an external thread, and the first pair of joints 2 is provided with an internal thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com