Wheel flange lubrication control method based on position information

A control method and position information technology, which is applied in the direction of track lubrication, track wetting/lubrication, railway car body parts, etc., can solve the problems of serious wheel rim wear, inaccurate spraying, lubricating oil consumption, etc., and prolong the service life of wheels , Reduce wheel flange wear and noise, reduce wheel-rail noise and running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

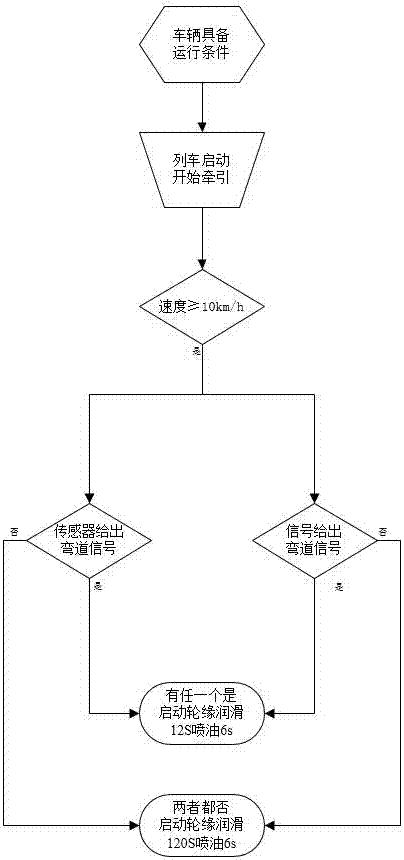

[0024] like figure 1 As shown, a wheel rim lubrication control method based on position information includes the following steps.

[0025] Step 1, subway vehicle running line preset: preset the subway vehicle running line in the vehicle control system VCU in advance, the subway vehicle running line includes all curved turns and the position of each curved turn; each curved turn includes curves and The transition curves located on both sides of the curve; the transition curves are all connected to the curve, and the length of the transition curves is not less than 20m.

[0026] The setting of the above-mentioned transitional curve can carry out injection lubrication at the transitional curve, reduce system delay and reduce the number of false injections.

[0027] Step 2, layout of trackside signaling equipment.

[0028] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com