Frame-free type novel vehicle manufacturing technique

A frameless, new process technology, applied in bicycles, motor vehicles, passenger bicycles, etc., can solve the problems of rot of attachments of iron structure, complex structure design, and complicated assembly process, so as to ensure safety and reduce production. Cost and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

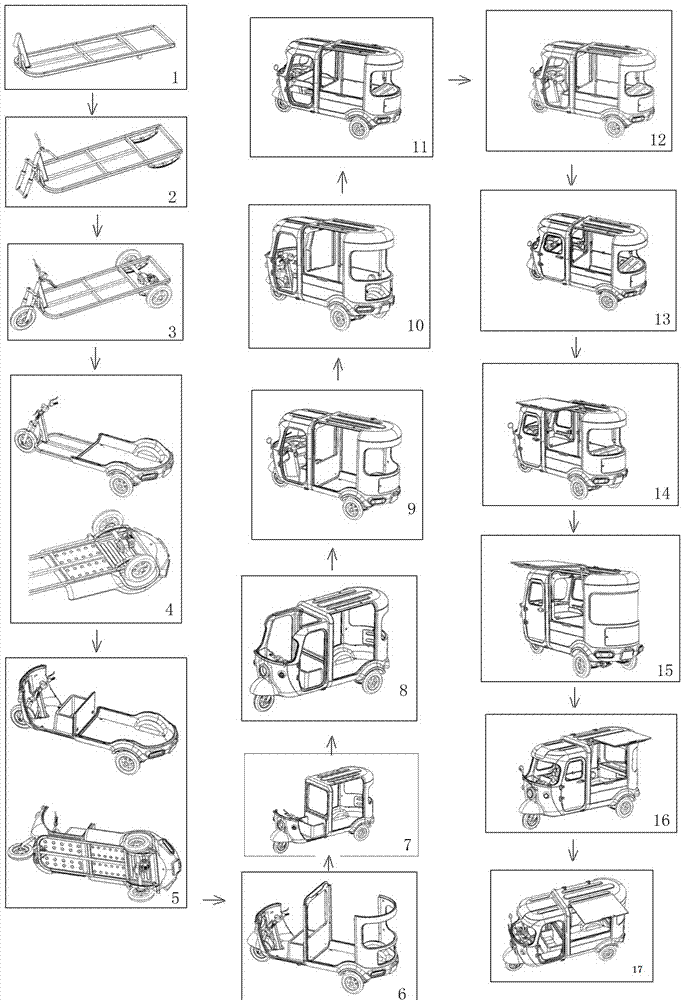

[0048] For ease of description, below in conjunction with accompanying drawing, the frameless type that the invention creates new technique is explained in detail.

[0049] Such as figure 1 as shown in

[0050] A new frameless car manufacturing process is to directly install the car body covering on the car body chassis, and install it layer by layer from bottom to top.

[0051] The entire installation process includes chassis preparation, installation of front forks and leaf springs, installation of rear axles, tires, motors and handlebars, installation of rear compartment pans, installation of front compartment pans, installation of rear compartment front and rear panels and front mudguard tiles, Install the roof of the rear compartment, install the left and right door frames of the front compartment, install the front roof, install the side baffles of the rear compartment, install the interior flap and tailgate, water tank, install the center console, install the doors, i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap