Anti-blocking device for discharging chute

A chute and anti-blocking technology, used in conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of being easily affected by the external environment, affecting coal carrying, and having limitations, so as to improve the working environment of employees and reduce The effect of coal flow stuffing the machine head and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

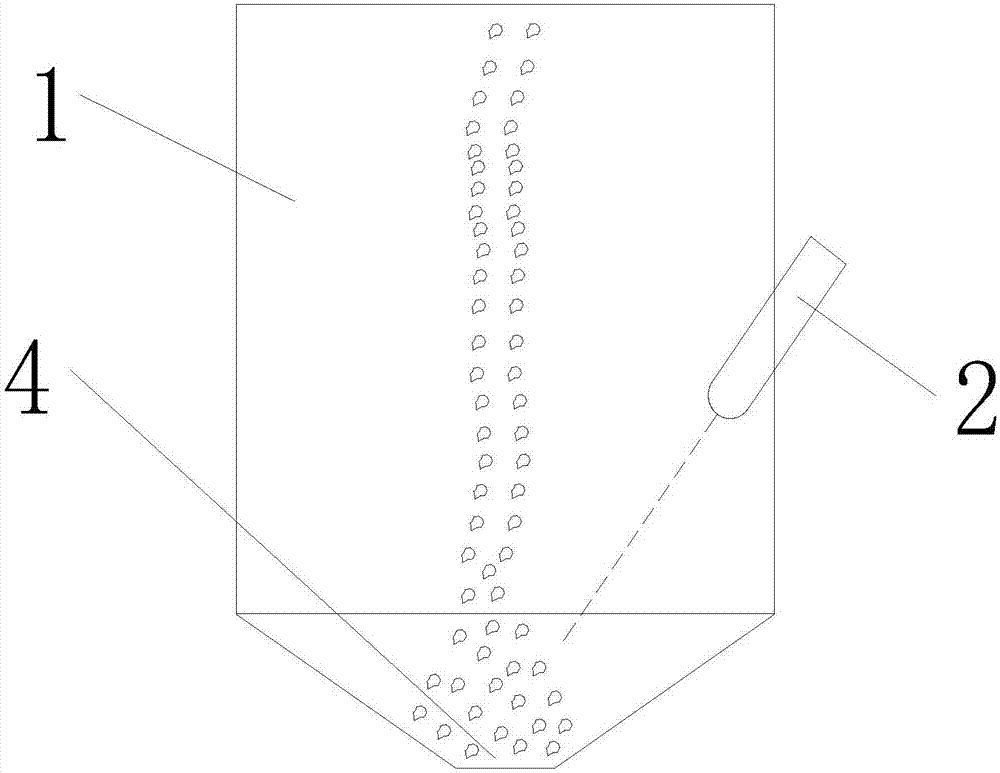

[0017] figure 1 Show the specific embodiment of the present invention: a kind of blanking chute 1 anti-blocking device, this anti-blocking device is arranged on the inside of blanking chute 1, this anti-blocking device is infrared sensor switch 2, the side wall of described blanking chute 1 is set There is a mounting hole 3, the infrared sensor switch passes through the mounting hole 3, and the sensor head of the infrared sensor switch is set toward the discharge port 4 of the feeding chute 1; the distance between the sensor head of the infrared sensor switch and the discharge port 4 is smaller than that of the infrared sensor sensor The sensing distance of the switch.

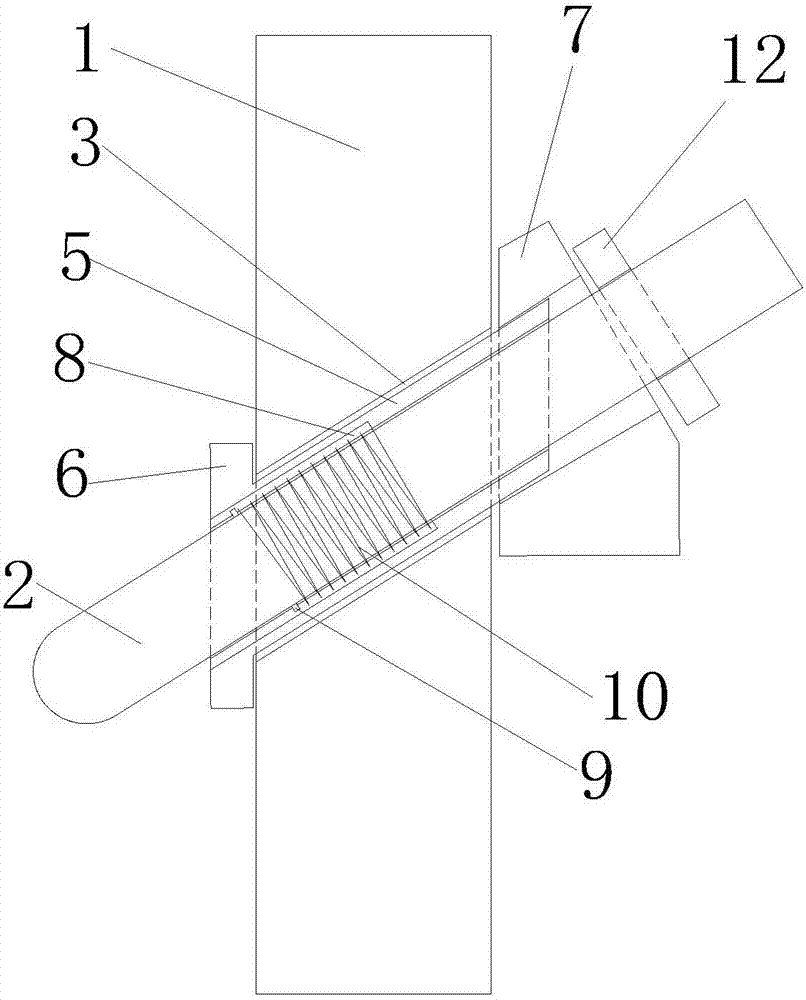

[0018] The installation hole 3 is arranged obliquely, the installation hole 3 is provided with a sleeve 5, and the infrared sensor switch is arranged in the sleeve 5; one end of the sleeve 5 is provided with a positioning plate 6, and the other end is provided with a screw-connected fixing plate 7. When the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com