Different quality water supply system

A technology for water supply by quality and water supply system, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems affecting water quality, secondary pollution, etc., to prevent secondary pollution Secondary pollution and bacterial growth, water quality protection, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

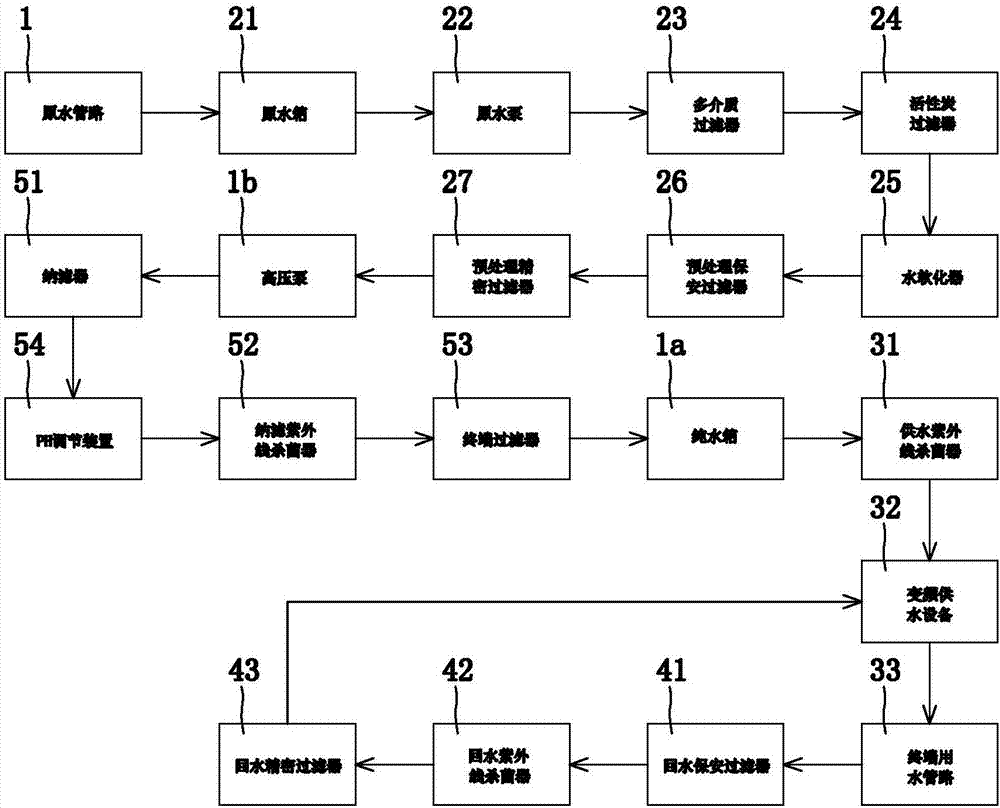

[0022] Embodiment 1: as figure 1 In the shown embodiment, a kind of qualitative water supply system comprises

[0023] Pretreatment system, terminal water supply system, return water quality assurance system, pure water tank 1a and high-pressure pump 1b for sending water treated by the pretreatment system into the pure water tank;

[0024] The pretreatment system includes sequentially connected raw water pipeline 1, raw water tank 21, raw water pump 22, multimedia filter 23 and activated carbon filter 24, and the terminal water supply system includes sequentially connected water supply ultraviolet sterilizer 31, frequency conversion water supply equipment 32 And terminal water pipeline 33;

[0025] The backwater quality assurance system includes a backwater security filter 41, a backwater ultraviolet sterilizer 42 and a backwater precision filter 43 connected in sequence, and the backwater ultraviolet sterilizer, backwater precision filter and pure water tank are connected in...

Embodiment 2

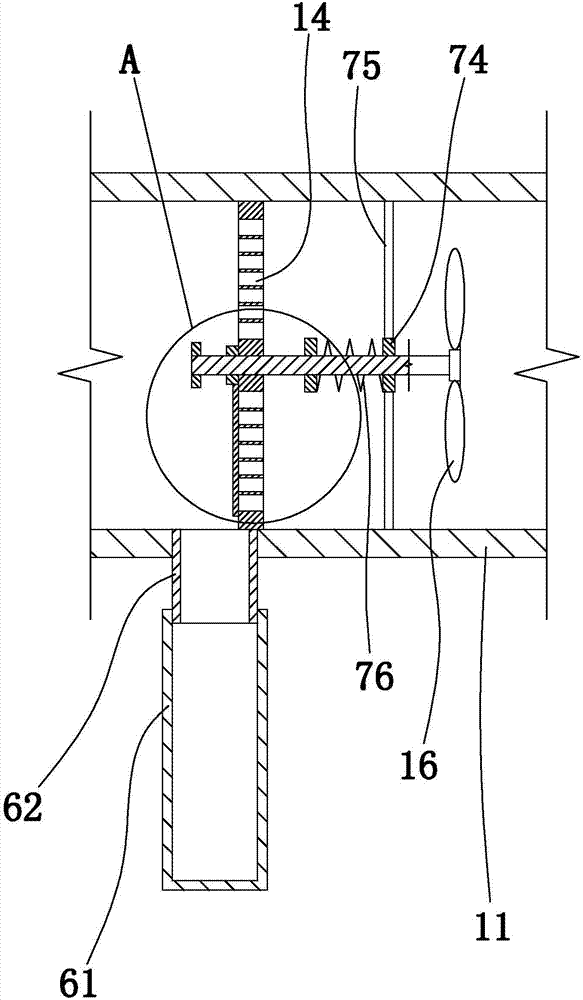

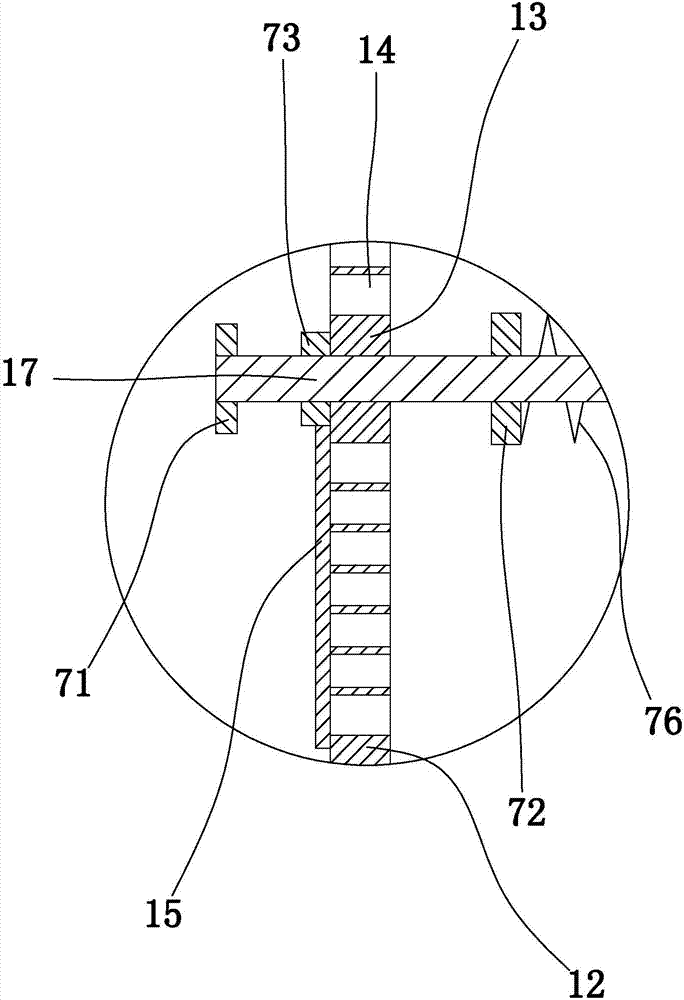

[0034] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 2 to Figure 3As shown in , the raw water pipeline includes a water inlet pipe and a water filter pipe 11, the water inlet pipe, the water filter pipe and the raw water tank are connected in sequence, the axis of the water filter pipe is horizontal, the outer fixed ring 12 and the inner fixed ring 13 are arranged in the water filter pipe, and the water filter pipe , the outer fixed ring and the inner fixed ring are coaxially arranged, the inner fixed ring is in the center hole of the outer fixed ring, and an annular coarse filter screen 14 is arranged between the inner fixed ring and the outer fixed ring, and the annular coarse filter screen and the outer fixed ring are fixed , the annular coarse strainer is fixed with the inner fixed ring, and the outer fixed ring is sealed with the inwall of the water filter pipe, and the water fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com