Cross bar type precast brick for cement kiln vertical walls

A cross-bar type, cement kiln technology, applied in the field of refractory materials, can solve the problems of large defects in pouring quality, frequent replacement of refractory linings, short service life, etc., and achieves improved thermal shock resistance, erosion resistance, low thermal conductivity, good alkali resistance. Aggressive, easy-to-position and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

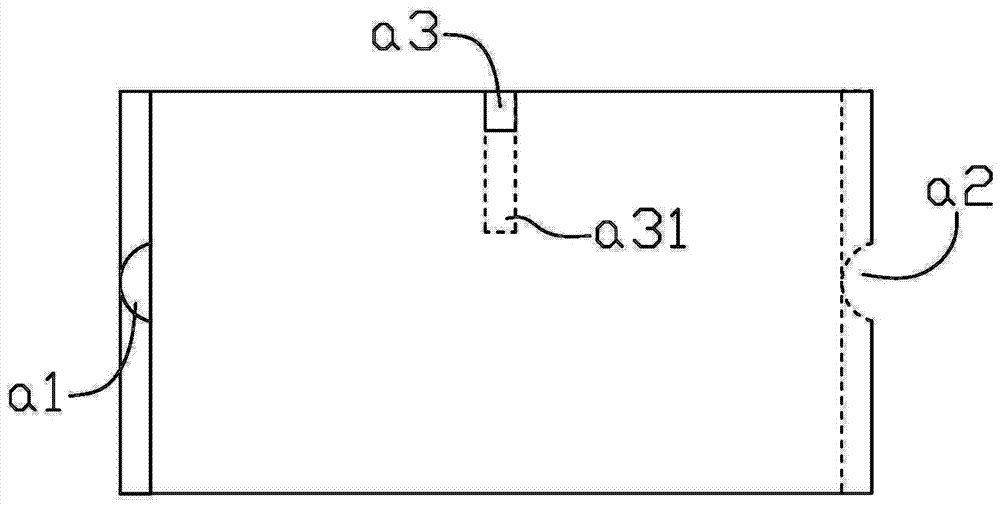

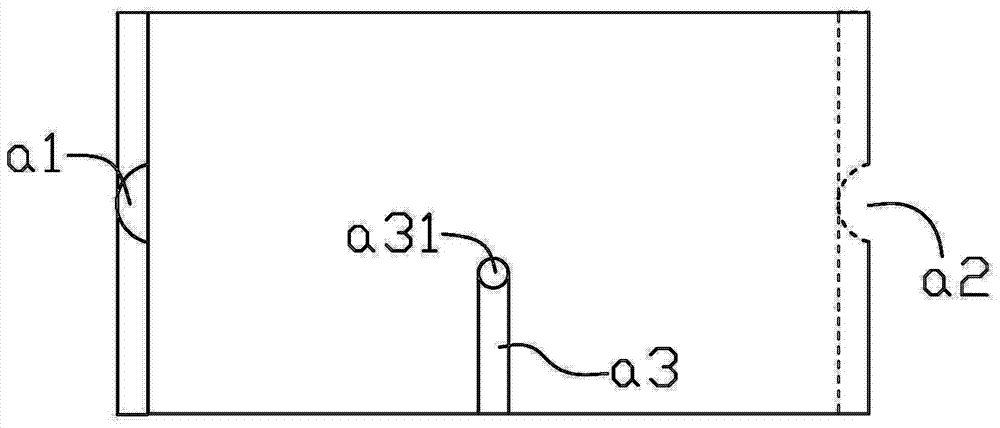

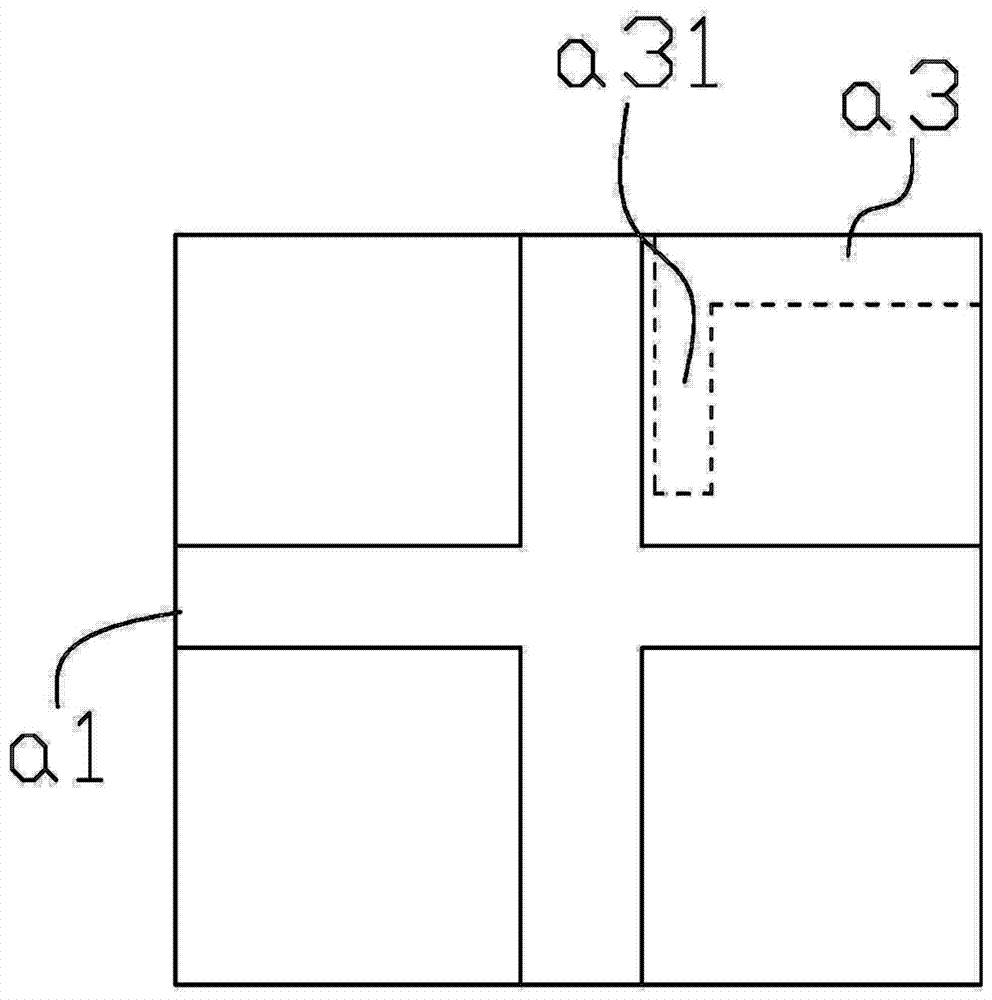

[0061] Example 1: Reference Figure 1~Figure 4 , a prefabricated brick for a cross-bar type cement kiln vertical wall, which is a body of a cube structure, one side of the body is provided with a cross-shaped snap-on protrusion a1, and the opposite side of the side where the snap-on protrusion a1 is located is provided with the same cross-shaped the snap-fit groove a2, the snap-fit protrusion a1 and the snap-fit groove a2 are both arc-shaped and compatible in outline;

[0062] The clamping protrusion a1 includes two staggered ridges, which are respectively parallel to the two sides of the rectangular surface, and the clamping groove a2 includes two staggered grooves, respectively penetrating the rectangular surface where it is located.

[0063] One side of the main body is provided with a steel drill slot a3, the surface where the steel drill slot a3 is located is perpendicular to the surface where the clamping projection a1 is located or the surface where the clamping g...

Embodiment 2

[0064] Example 2: Reference Figure 5 , a prefabricated brick for a vertical wall of a cross-bar type cement kiln, the difference from Embodiment 1 is that one side of the prefabricated brick is provided with a stepped card table, and its opposite side is provided with a contour matching it. card table.

[0065] The prefabricated brick preparation process of embodiment 3~embodiment 6 is as follows:

[0066] ①Mixing: Prepare the main ingredients according to the formula, put them in the mixer for stirring, then add the external ingredients and water, and continue to stir. ②Shaping: Add the stirred mixture into the mold, spread it out by the self-weight and surface tension of the mixture, and wipe off the excess mixture on the surface;

[0067] ③Maintenance: Put the mold with the mixture into a constant temperature environment of 25℃, demould after hardening, and leave it for 48 hours after demoulding;

[0068] ④Drying: Place the cured bricks in an electric kiln for drying at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com