Automatic back-stranding cable preparation method and preparation equipment employing same

A cable and equipment technology, which is applied in the field of automatic twisted cable preparation, can solve the problems of wasting time, wasting man-hours, and unable to correct cable errors, so as to reduce labor pressure, reduce the rate of defective products, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

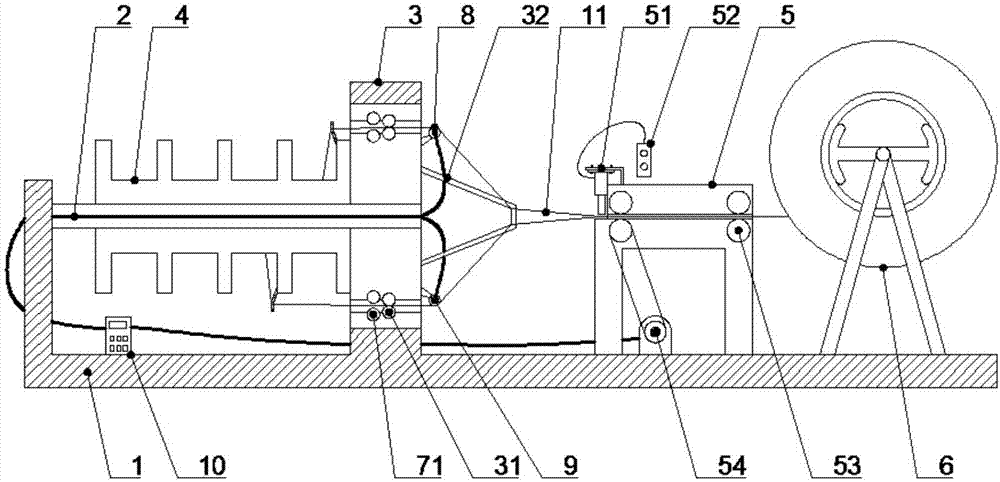

[0034] Such as figure 1 A cable preparation method capable of automatic twisting is shown, including a frame 1, a power shaft 2, a wire splitting turntable 3, a wire splitting rack 4, a wire closing winch 5, a bus rack 6, and a twisting back control mechanism 7 and the product cable 11, including the following steps: 1) The frame 1 is provided with a power shaft 2, the power shaft 2 is connected to the frame 1 through bearings, and the power shaft 2 is provided with a line dividing turntable 3, One side of the splitting turntable 3 is provided with a splitting material rack 4, one end of the frame 1 is provided with a closing winch 5, and one side of the closing winch 5 is provided with a bus rack 6; 2) the splitting A number of through holes are provided on the wire turntable 3, and a tensioning wheel 31 and a twisting control mechanism 7 are arranged in the through holes, and a guide wheel 8 is arranged at one end of the through holes; 3) charging, installing the product cab...

Embodiment 2

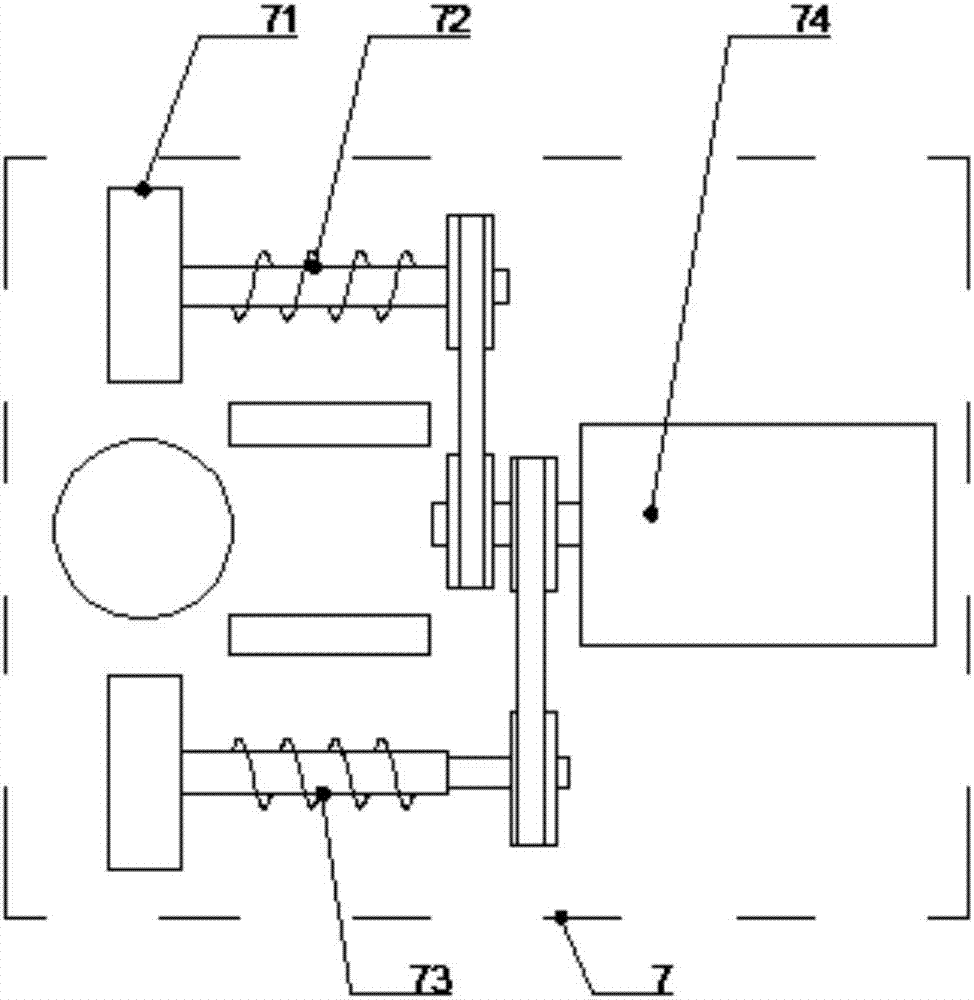

[0042] Such as figure 2A cable preparation method capable of automatic twisting is shown, including a frame 1, a power shaft 2, a wire splitting turntable 3, a wire splitting rack 4, a wire closing winch 5, a bus rack 6, and a twisting back control mechanism 7 and the product cable 11, including the following steps: 1) The frame 1 is provided with a power shaft 2, the power shaft 2 is connected to the frame 1 through bearings, and the power shaft 2 is provided with a line dividing turntable 3, One side of the splitting turntable 3 is provided with a splitting material rack 4, one end of the frame 1 is provided with a closing winch 5, and one side of the closing winch 5 is provided with a bus rack 6; 2) the splitting A number of through holes are provided on the wire turntable 3, and a tensioning wheel 31 and a twisting control mechanism 7 are arranged in the through holes, and a guide wheel 8 is arranged at one end of the through holes; 3) charging, installing the product cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com