Organic light-emitting diode (OLED) display panel and display device

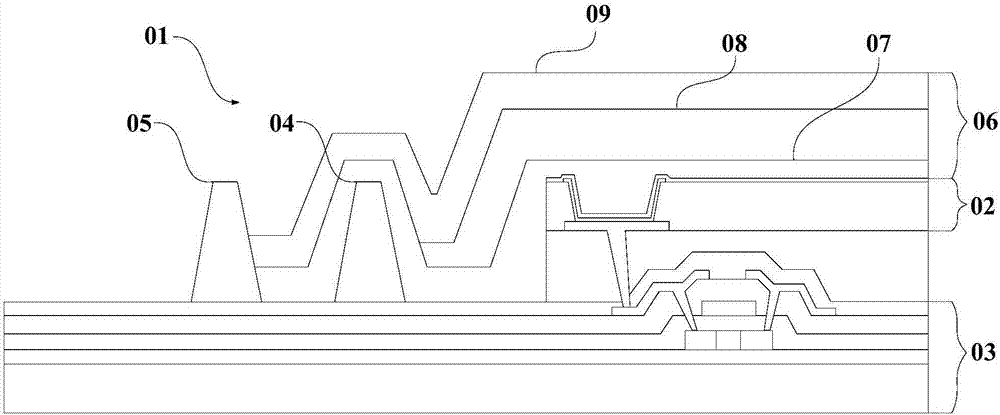

A technology for display panels and display areas, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as cracks, OLED device failure, and thin film encapsulation layer and substrate peeling, and achieves improved bending reliability and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

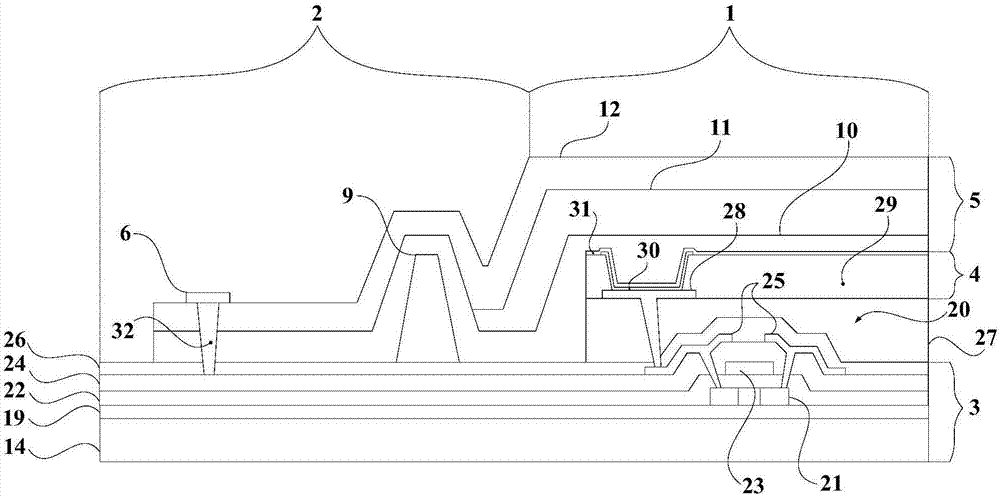

[0050] In order to improve the bending reliability of the OLED display device and prolong the service life of the OLED display device, an embodiment of the present invention provides an OLED display panel and a display device. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

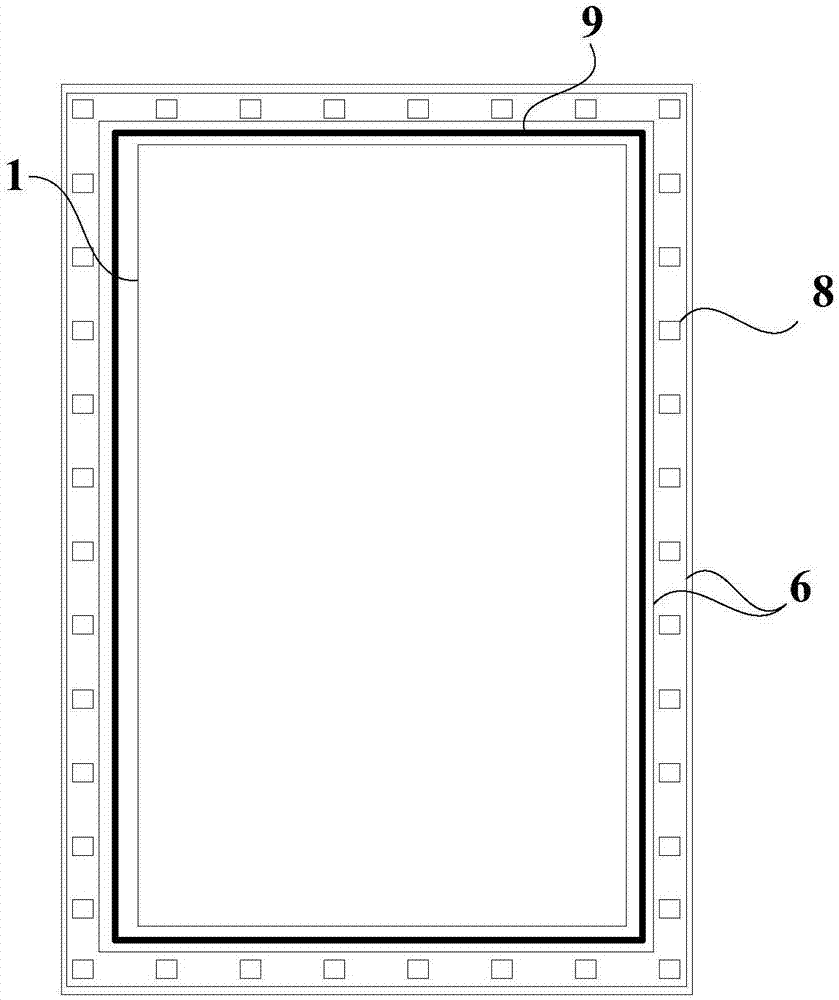

[0051] Such as figure 2 As shown, the embodiment of the present invention provides an OLED display panel, including a display area 1 and a peripheral area 2 outside the display area 1. The OLED display panel includes an array substrate 3, a light emitting unit 4 and The thin film encapsulation layer 5 , and the nail wall structure 6 disposed on the peripheral area 2 , wherein: the nail wall structure 6 penetrates the thin film encapsulation layer 5 and enters the array substrate 3 .

[0052]In the OLED display panel of the embodiment of the present invention, the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com