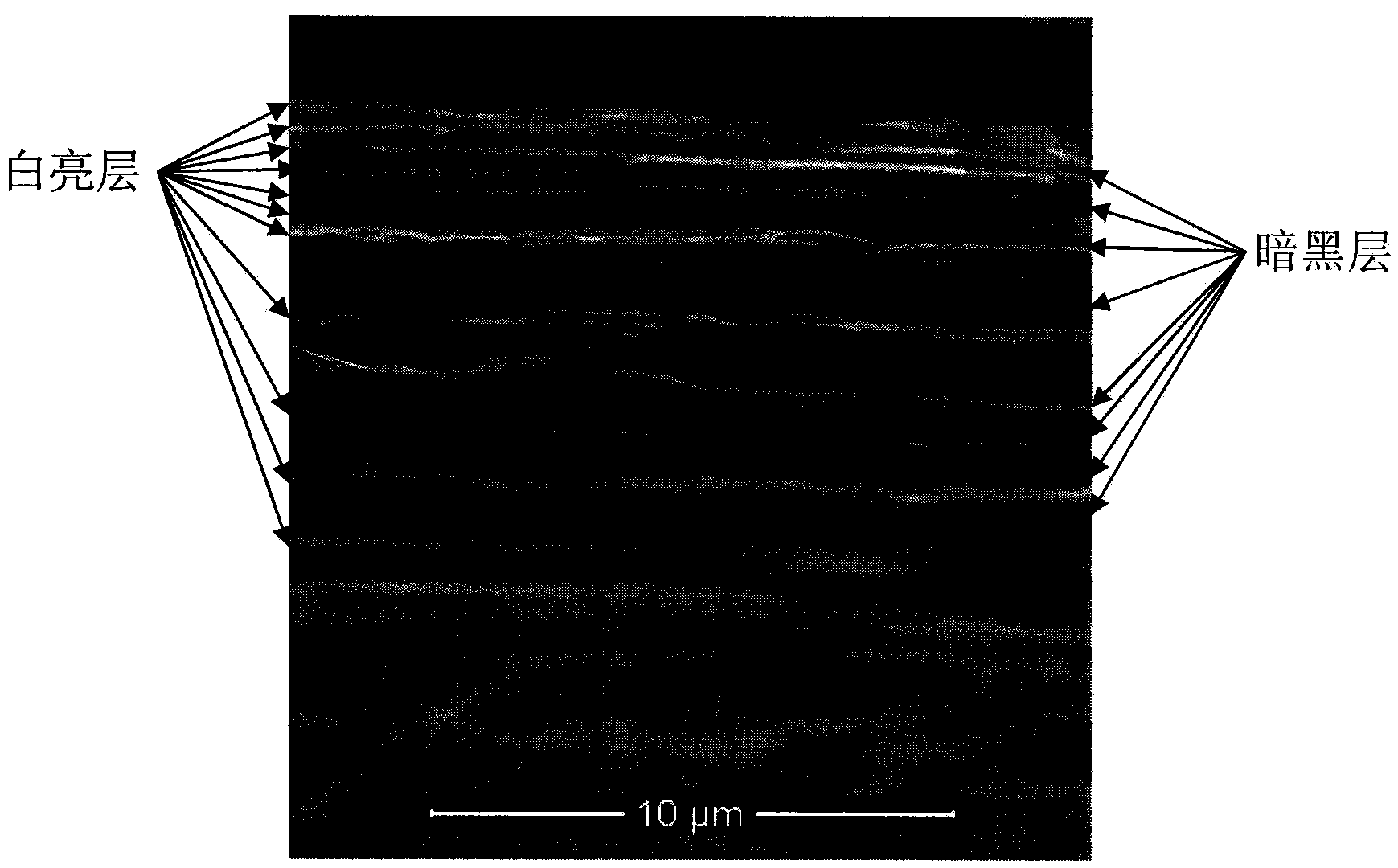

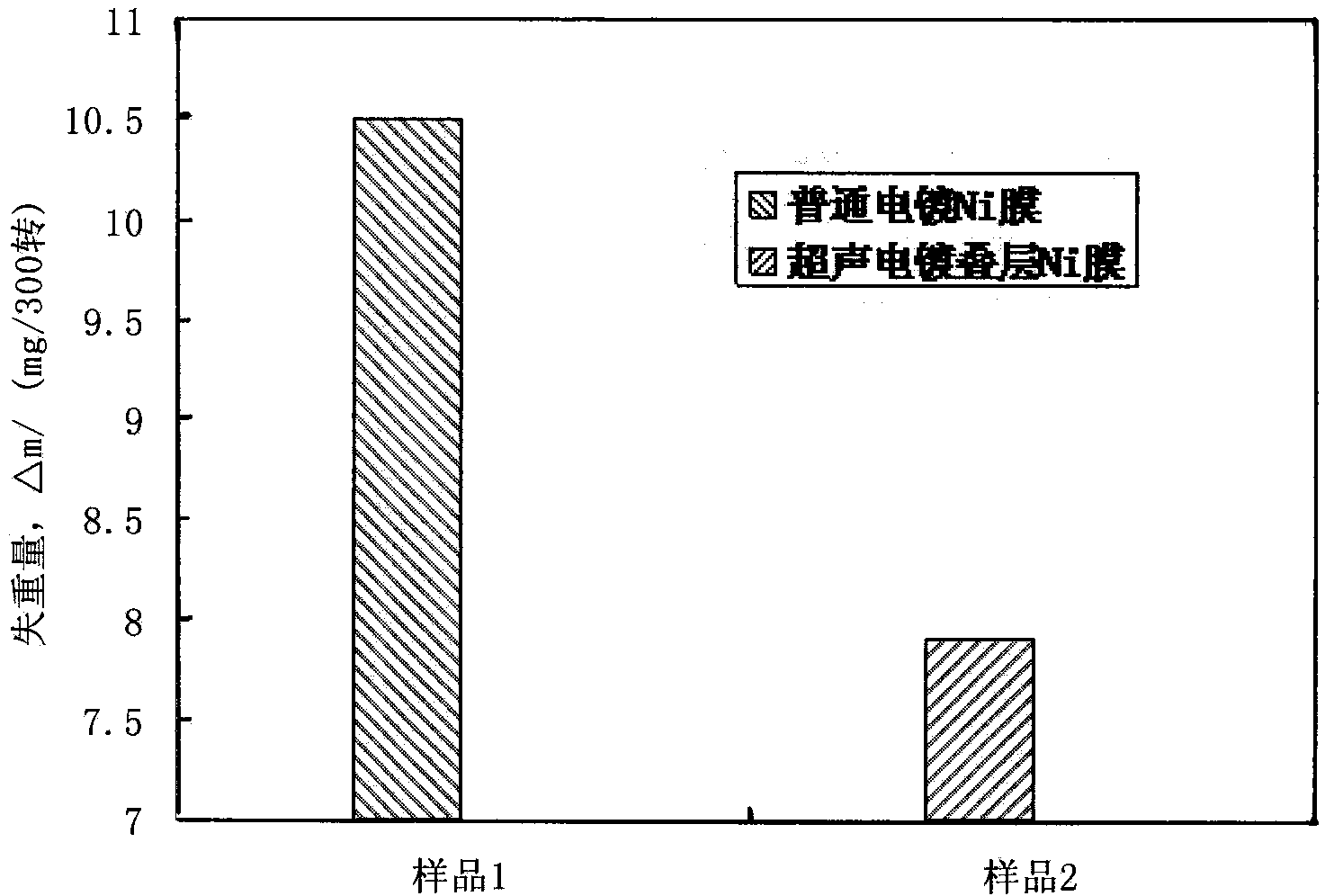

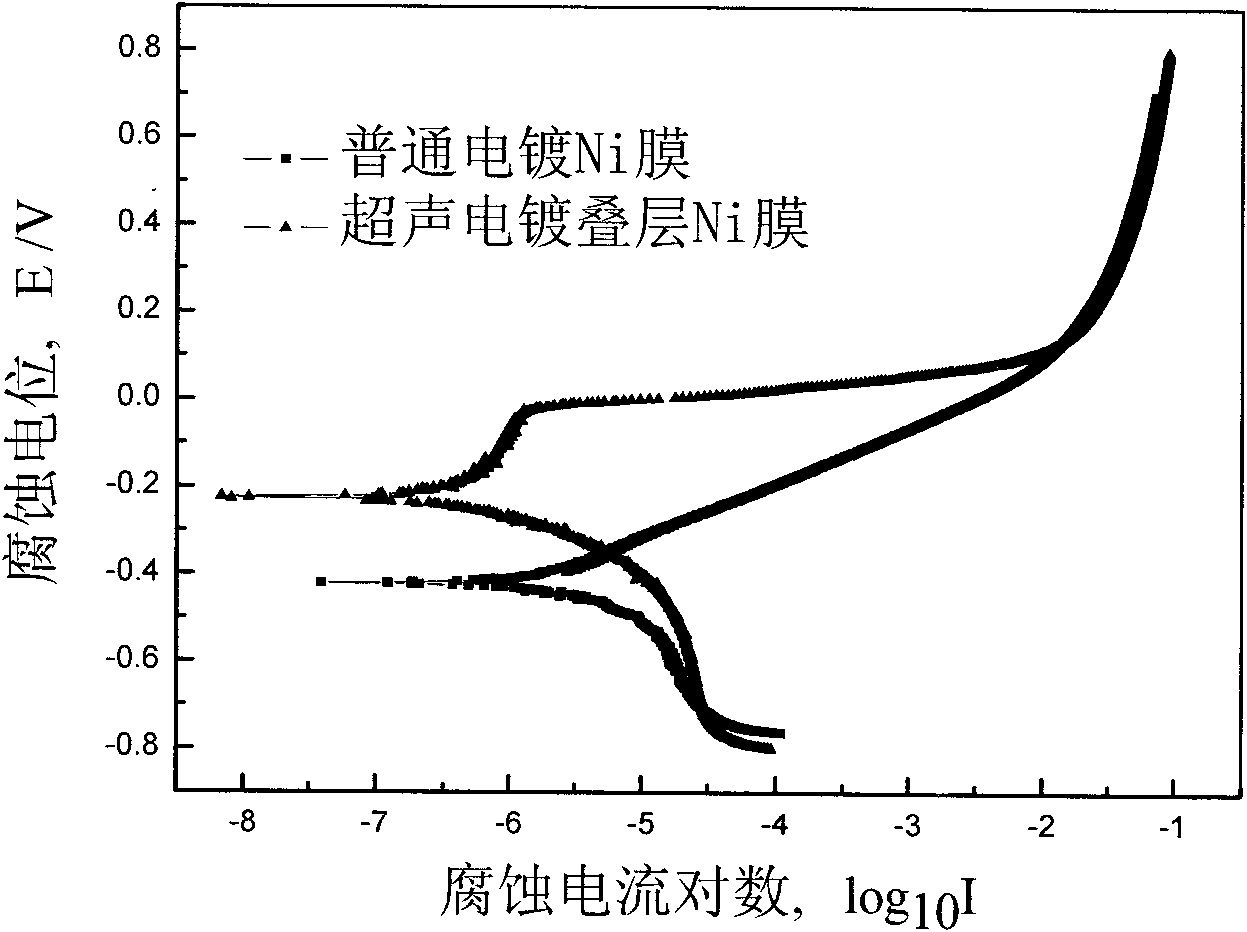

Electroplated Ni stacking membrane and its preparation method

A technology of laminated film and nickel film, which is applied in the field of electroplating Ni laminated film and its preparation, can solve problems such as crack propagation, microcracks, and increased brittleness tendency, and achieves low cost, excellent wear resistance, and simple and easy preparation method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] After the surface is degreased, it is ultrasonically cleaned in an organic trichlorethylene solution for 5 minutes and then acid-etched and washed with water. The cleaned 304 stainless steel base material is connected to the cathode of the electroplating power supply, and the anode is made of pure nickel plate (nickel content 99.9wt) %), start the ultrasonic generator CSF-1A, adjust its current to 100mA, then hang the plated parts into the electroplating solution placed in the ultrasonic cleaning tank to start electroplating, the electroplating solution formula and process parameters are basically the same as those shown in Table 1. The nickel solution is the same, and the current density applied to the workpiece is 3A / dm 2 , when the coating reaches 120 seconds, the current of the ultrasonic generator is gradually (uniformly) reduced to 0 within 10 seconds, and then the coating is performed without ultrasound for 40 seconds, and then within 10 seconds, the current of th...

Embodiment 2

[0048] The difference from Example 1 is:

[0049] After the surface is degreased, it is ultrasonically cleaned in an organic solution of trichlorethylene for 8 minutes and then acid-etched and washed with water. The cleaned No. 45 steel base material is connected to the cathode of the electroplating power supply, and the anode is made of pure nickel plate (nickel content 99.9%) wt%), start the ultrasonic generator CSF-1A, adjust its current to 150mA, then hang the plated parts into the electroplating solution placed in the ultrasonic cleaning tank to start electroplating, the electroplating solution formula and process parameters are basically the same as those shown in table 1 The nickel plating solution is the same, and the current density applied to the workpiece is 2A / dm 2 , when the coating reaches 120 seconds, the current of the ultrasonic generator is gradually (uniformly) reduced to 0 within 60 seconds, and then the coating is performed without ultrasound for 120 secon...

Embodiment 3

[0052] The difference from Example 1 is:

[0053] After the surface is degreased, it is ultrasonically cleaned in an organic solution of trichlorethylene for 10 minutes and then acid-etched and washed with water. The cleaned aluminum alloy base material is connected to the cathode of the electroplating power supply, and the anode adopts a pure nickel plate (nickel content 99.9wt) %), start the ultrasonic generator CSF-1A, adjust its current to 200mA, then hang the plated parts into the electroplating solution placed in the ultrasonic cleaning tank to start electroplating, the electroplating solution formula and process parameters are basically the same as those shown in Table 1. The nickel solution is the same, and the current density applied to the workpiece is 12A / dm 2 , when the coating reaches 300 seconds, the current of the sonotrode is gradually (uniformly) reduced to 0 within 60 seconds, and then the film is coated for 300 seconds without adding ultrasound, and then wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com