A rectifier and its control method

A control method and a technology of a rectifier, which are applied to conversion equipment without intermediate conversion to AC, irreversible AC power input conversion to DC power output, and output power conversion devices, etc., which can solve the problem of large output current ripple and high output voltage. , Difficult selection of power tubes and other issues to achieve reliable and stable work and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

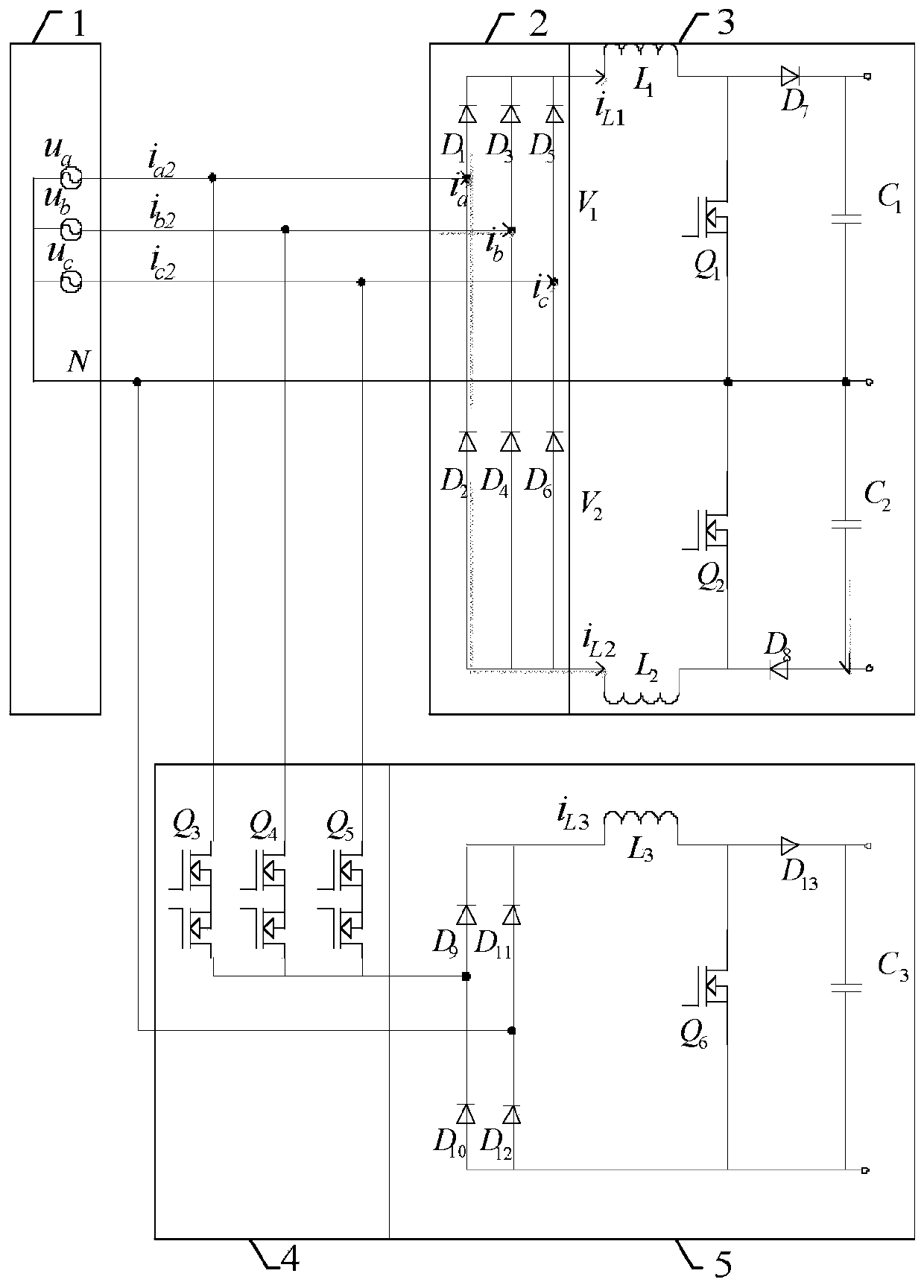

[0032] The invention will be described in further detail below in conjunction with the accompanying drawings.

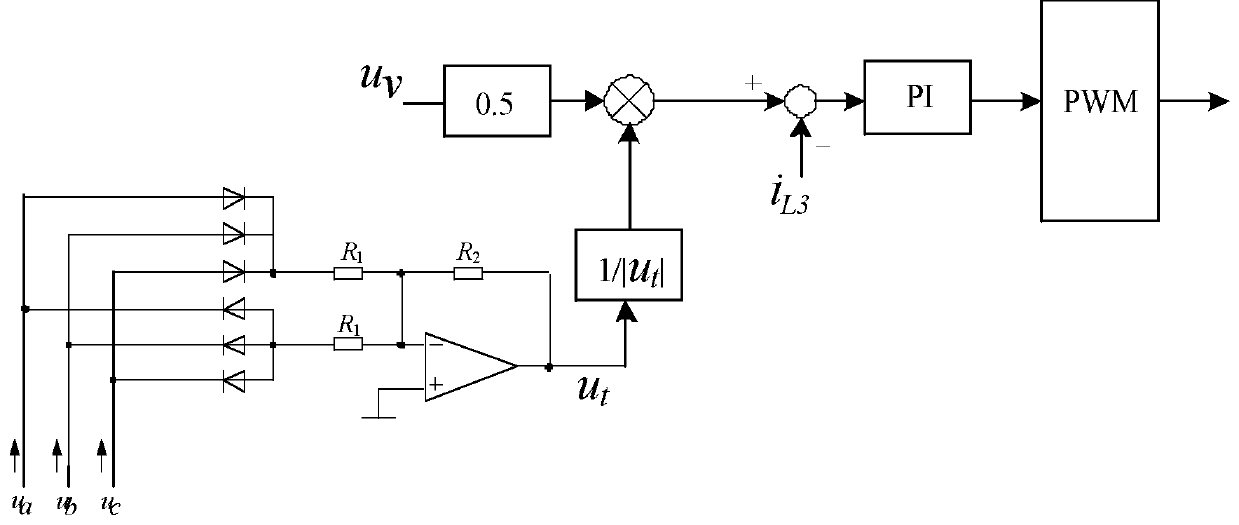

[0033] The three-phase double-half-wave boost PFC power factor correction of the present invention adopts three-phase half-wave rectification combined with two boost switch tubes, the circuit works in the continuous mode of inductive current, and the waveform compensation circuit is input to the three-phase double-half-wave boost PFC power factor correction circuit The middle 2 / 4 part of the current (-30° to 30°, 150° to 210°) is compensated so that the phase input current is a complete sine wave to achieve complete power factor correction.

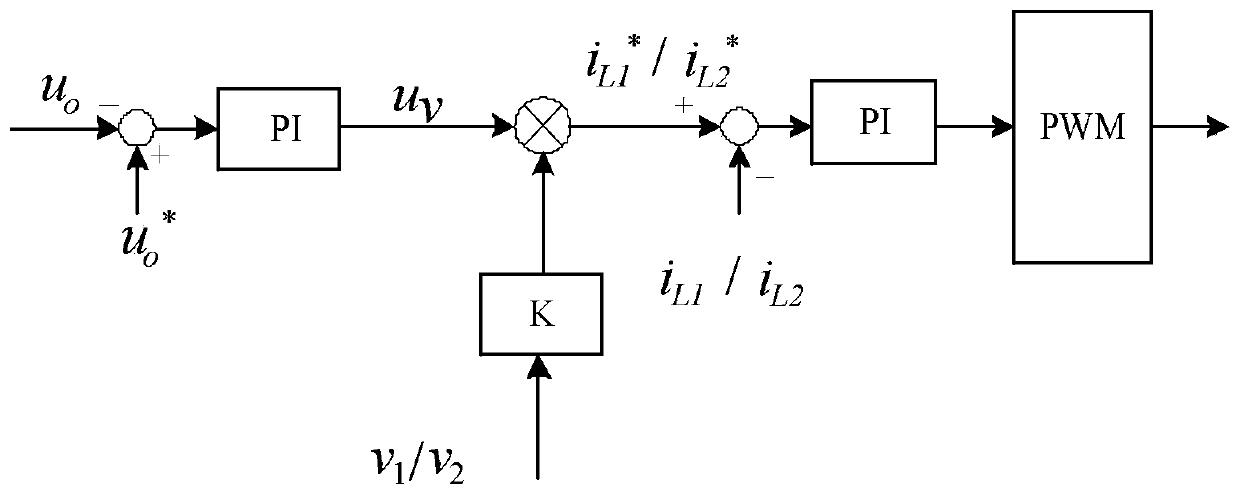

[0034] Such as figure 2 Shown, the output voltage sampling value u 0 and a given value u 0 * After making the difference, it is adjusted by PI to form the inner loop current amplitude signal u v , which is multiplied by the unit half-wave rectified voltage signal to obtain the given signal i of the inner loop L1 * / i L2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com